Application of High Pressure Soft Start on Compressor Load

Abstract: The high-voltage and high-power motor has a relatively large impact on the load and the power grid when starting. Thyristor series high-voltage soft starters are widely used for their superior starting performance and other advantages. This article analyzes its working principle through the application of high-voltage soft starter to the load of high-power compressor on site, introduces the starting function, and makes a more comprehensive introduction to the high-voltage soft start of thyristor series connection.

Keywords: thyristor, motor, trigger, soft start

1. Introduction

AC asynchronous motors have been widely used in my country's coal mines, petroleum, chemical, steel, power generation, water supply, cement and building materials with their simple structure, extremely high operational reliability, strong environmental adaptability and excellent drag performance. . But the fatal disadvantage of AC asynchronous motors is that they have a large starting shock, which will have an adverse effect on the system. The main impact is reflected in two aspects:

(1) Electrical problems:

It can reach 5-7 times the rated current when starting, causing the motor winding to overheat due to the current, thereby accelerating its insulation aging, causing voltage fluctuations in the power supply network, and affecting the normal operation of other equipment under the same power grid.

(2) Mechanical problems:

Excessive starting torque produces mechanical shock, which will cause a large impact on the driven equipment, shorten the service life, and affect accuracy. Such as damage to the coupling, torn belt, etc. Causes abnormal wear and impact of mechanical transmission components, accelerates aging, shortens life and increases maintenance workload.

This problem was encountered in the air compressor of the nitrogen production line of Shougang Cold Rolling Plant. Due to the relatively large motor power (10KV/3730KW and 10KV/2250KW), the mechanical impact on the motor and compressor during the starting process is relatively large. This increases the workload for system maintenance; secondly, the power grid drops severely when the motor is directly started, and other equipment cannot work normally when the grid voltage drop reaches 85%. In view of the above reasons, it was decided to use the PowerEasy type thyristor soft start device.

2. The composition and principle of thyristor series high voltage soft start

2.1 Main circuit composition

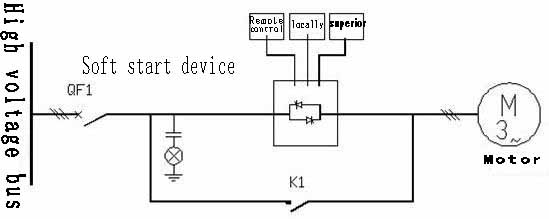

The thyristor series soft starter is a fully digital and intelligent starting device that combines power electronic technology, photoelectric technology control technology and micro-processing technology. The wiring diagram of the main circuit of the thyristor series soft starter is shown in Figure 1. It is mainly composed of a high-voltage thyristor series valve group and a bypass contactor. The high-voltage thyristor series valve group is the power conversion executive component, which consists of multiple thyristors It is composed of series and parallel connections, supplemented by absorption and voltage equalization clamping circuits to ensure its reliability in high-voltage environments. When the incoming line terminal is powered, the AC three-phase power supply is chopped by controlling the conduction angle of the thyristor to control the amplitude of the output voltage. After the start process is completed, the bypass contactor is closed, the soft start device is switched to the bypass state, and the thyristor is closed at the same time.

Figure 1 Wiring diagram of the main circuit of soft starter in series with thyristor

2.2 Control circuit

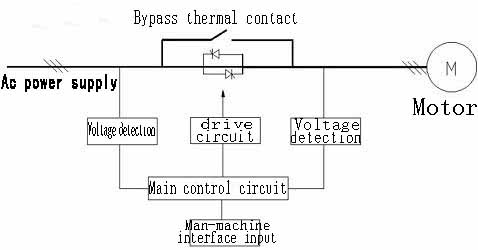

As shown in Figure 2, the control circuit of the thyristor series high-voltage soft starter is generally composed of a main control circuit, a trigger device, a signal acquisition circuit and a man-machine interface.

Figure 2 Block diagram of soft start control

2.2.1 Main control circuit

The main control circuit is mainly composed of a digital circuit composed of a DSP microprocessor and a large-scale CPLD gate array. Its main function is to generate a pulse command to trigger the thyristor, and the trigger command of the thyristor is issued through a digital signal processor (DSP). The main control circuit can adjust the conduction angle of the thyristor according to the voltage and current signals collected by the signal acquisition circuit, so as to achieve the function of adjusting the motor current and realize the closed-loop control of the motor, that is, the current limit start. While sending out the trigger pulse, it can monitor the running status of the motor and the soft starter itself through feedback signals such as voltage, current and temperature, so as to protect the entire system and ensure the safe operation of the system.

2.2.2 Trigger system

The trigger system is a key part of the system's stability and reliability. It must have the ability to resist noise interference and be able to turn on the thyristor in a timely and accurate manner. There are mainly two technical problems here:

1. The trigger pulse can trigger the thyristor timely and accurately

The thyristor is a current-controlled bipolar semiconductor component. It requires the gate drive unit to be similar to a current source, which can provide a particularly steep spike current pulse to the thyristor to ensure accurate and reliable triggering at any time Thyristor. Therefore, the gate trigger pulse characteristics of the thyristor have a very strong influence on the normal operation of the thyristor.

When the thyristors are used in series, we require the thyristors connected in series to be turned on together as much as possible, because the slower turn-on may withstand overvoltage and damage the components. At this time, the turn-on time difference of the thyristors in the same group in series is required to be as small as possible.

The turn-on speed of the thyristor is mainly related to the amplitude of the gate trigger pulse and the steepness of the rising edge of the pulse. That is to say, the greater the amplitude of the gate trigger pulse, the steeper the rising edge of the pulse, and the shorter the turn-on time of the thyristor. Therefore, in the field of motor soft start, most manufacturers use strong triggering to trigger the thyristor. That is, the current amplitude of the trigger pulse IG is greater than or equal to 10IGT, and the pulse rising edge time tr≤1μs. In short. In order to ensure the reliability of the thyristor valve string, IG is much larger than IGT.

2. Trigger method of trigger thyristor

There are three trigger systems for high voltage isolation, pulse transformer, direct light trigger and fiber optic trigger. The pulse transformer has a simple structure and low cost, but its electromagnetic compatibility is poor, and it is not suitable for use in a high-voltage environment; although the direct light trigger system is reliable and accurate, it is expensive and rarely used; the optical fiber trigger system has good reliability, although compared with direct light The trigger system adds some complexity to the circuit, but the relative cost is much lower and the trigger is accurate and reliable, so it is the first choice for high-voltage applications. At present, the trigger systems of high-voltage soft starters on the market basically use optical fiber trigger systems.

In the high-voltage soft start, the working power of the trigger system is generally obtained by high-level power, that is, the working power of the trigger circuit board is supplied by the capacitor on the dynamic voltage equalization (ie RC absorption circuit), so as to avoid the use of high withstand voltage transformers. The high cost comes, and electrical isolation is realized to avoid interference of the trigger signal. It should be pointed out that this method of high energy extraction is only applicable during the soft start process, and in the soft shutdown process designed for some pump loads, because the current in the main circuit is getting more and more in the second half of the stop process. If it is small, it will affect the acquisition of electric energy on the trigger board, thereby affecting the triggering of the thyristor. Therefore, the thyristor soft starter of some manufacturers will separately provide additional power to the trigger system when producing products with soft stop function, which increases the cost. And the soft starter of some foreign companies such as AB has relatively perfect technology in this respect. They use a technology called low-level energy extraction, that is, a low-voltage high-power transformer is used on the low-voltage side, and a low-voltage high-power transformer is used on the trigger board. A set of current sensing device, passing the wire of the transformer through the current sensing device on the trigger board to obtain the induced current on the trigger circuit board to act as a power source, so that the trigger board can obtain enough power to continue triggering in the late stage of soft parking The thyristor can make the late parking process of soft parking more stable and reduce the impact of the water hammer effect of the pump load on the pipeline and the impeller.

2.2.3 Signal acquisition circuit and man-machine interface

The main function of the signal acquisition circuit is to collect various signals and preprocess them, and then feed the processed signals back to the main control circuit. At present, there are two main types of collected signals, voltage signals and current signals. Some soft start manufacturers also collect temperature and speed signals. Voltage and current signals are generally collected through transformers, and fed back to the main control circuit after processing. The operating status of the motor and soft starter is judged based on the feedback data, and trigger pulses are sent out or judged by the feedback signal when the overall system operation is abnormal. Fault and issue a protection command.

The man-machine interface circuit is generally composed of a liquid crystal screen and a keyboard, which is used to complete the user's parameter setting, select the starting mode and display the operating status of the system. In some working conditions that require remote control, some soft starters are also equipped with remote communication modules.

3. Starting method of thyristor soft start

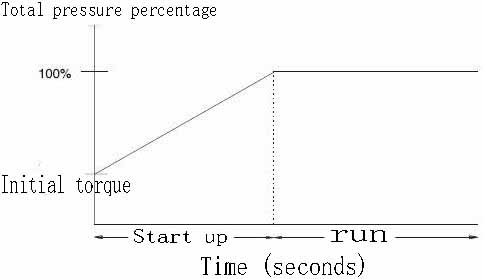

3.1 Full pressure start

In this state (Figure 3), the soft starter is equivalent to a solid-state contactor, and the motor is the same as a direct starter, withstands all current and torque shocks. In general, the thyristor full open time is controlled within 0.25s:

Figure 3 Full pressure start

3.2 Voltage ramp start

This mode is a long-term starting mode. By reducing the impact of the starting torque, it realizes the smooth and continuous stepless acceleration of the start of the motor, thereby minimizing the friction of gears, couplings and belts. The user can adjust the initial torque of the motor. During the acceleration ramp time, the input voltage of the motor rises linearly from the voltage corresponding to the set initial torque. The traditional step-down starting is changed to stepless, which can make the motor smooth Start, reducing the mechanical impact.

Figure 4 Voltage ramp start

3.3 Current limit start

Current limiting starting, as the name implies, is to limit the starting current to below a certain set current value during the motor starting process. It is mainly used for relatively light load starting and certain requirements for grid impact. Its input voltage increases rapidly from zero until its current reaches the preset current limit, and then it is ensured that the output current is not greater than the current In the case of the limit value, change the conduction angle of the thyristor and gradually increase the voltage until the rated voltage. At the same time, the speed of the motor is gradually increasing, reaching the rated speed. The advantage of this kind of starting is that the starting current is small, the impact of the motor starting on the power grid can be minimized, and the current limit value can be set as required. But when setting the current limit, it must be set according to the initial torque of the motor, otherwise the setting will fail to start or burn the motor if the setting is too small. The starting time of this starting mode is relatively long.

Figure 5 Current limit start

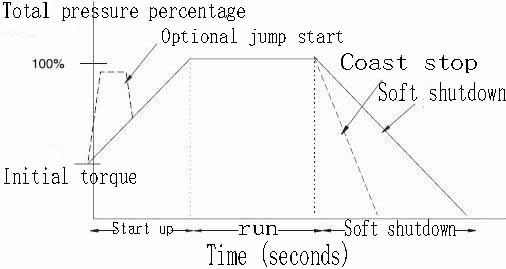

3.4 Kick start

This starting method is mainly used in a relatively heavy work environment. On the basis of torque control, a sudden jump torque is used to overcome the static torque of the load at the moment of starting, and then the torque gradually rises until the motor reaches the normal working state. The advantage of this starting method is that it can shorten the starting time and start a heavier load, but it will have a certain impact on the power grid when starting, and affect the work of other loads on the same power grid.

Figure 6 Sudden jump start

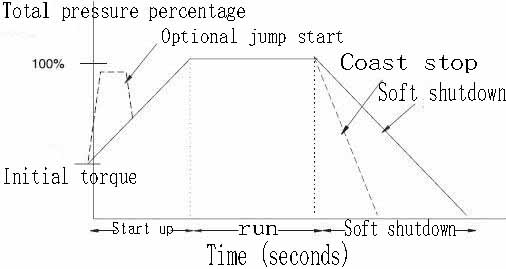

3.5 Soft parking

The soft stop is actually equivalent to the opposite soft start process. The main function is to eliminate the anti-inertia impact of the system. For pump loads, it overcomes the "water hammer" effect. The main process is that the bypass contactor of the soft starter is disconnected when the motor is soft-stopped, and the thyristor starts to work at the same time, so that the voltage of the motor is gradually reduced and the speed is reduced to achieve the effect of soft-stop. (Figure 7)

Figure 7 The whole process of soft start and soft stop

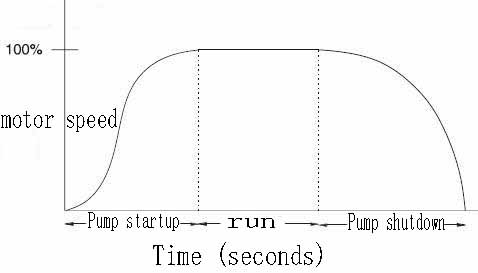

3.6 Pump control start and stop

Due to the relatively special mechanical characteristics of water pump loads, some soft start manufacturers have specially designed pump-controlled starting and stopping methods for the characteristic curve of pump loads. This starting method can smoothly accelerate and decelerate the motor to make the centrifugal pump operate Reduce water hammer impact during start and stop. The main control circuit analyzes various operating parameters of the motor by collecting signals, and at the same time controls the state of the motor by changing the conduction angle of the thyristor, so as to reduce the possibility of the system being impacted by surge. (Picture 8)

Figure 8 Pump control start and stop process

4. Application effect of soft start in compressor load

In the high-voltage and high-power compressor load system (10KV/3730KW and 10KW/2250KW) of the Shougang Cold Rolling Plant, the direct start of the motor will not only impact the power grid, but also put forward high requirements for the mechanical maintenance of the entire system. After using PowerEasy soft start, the effect is good and the expected purpose is achieved. The main application effects are reflected in the following aspects:

1) Compared with the on-site 10KV/3730KW compressor, its rated current is 253A, and the current will reach about 7 times the rated current when directly started. After using the

PowerEasy soft starter, according to the on-site working conditions, the starting mode is set to current limit start, the current limit multiple is 3.2 times, the current is about 810A when starting, and the current control is accurate and stable.

This not only reduces the impact of the motor starting on the power grid, but also improves the safe operation of the power grid. From another aspect, it relatively reduces the power grid capacity, reduces investment costs, and shortens the construction period.

2) While reducing the impact of the compressor directly on the motor itself, it also reduces the mechanical impact on the bearings, piping and the entire system. Because the motor directly starts and accelerates too fast, it is a very severe test for the life and reliability of the transmission system. The soft start process is smooth and stable, which can effectively eliminate the adverse effects on the transmission system and pipelines, reduce maintenance workload, and extend working life.

3) The main circuit of the PowerEasy soft starter adopts imported thyristors in series, with good consistency of power components and sufficient margin in the design. The temperature rise is relatively small when starting 3 to 5 times continuously. High reliability can be guaranteed under the working environment.

4) The PowerEasy soft starter mainly uses the current closed loop method to control and monitor the motor and the entire system. The starting process has good consistency under reasonable voltage fluctuations. And the soft start itself has a relatively complete protection system, which can protect and monitor the entire system at any time according to the feedback signal, which fully guarantees the safe operation of the system.

5) During the commissioning process, various protection parameters and starting parameters can be set according to the on-site working environment, which can better adapt to the on-site working conditions.

6) The volume is relatively small, the mechanism design is reasonable, and the noise is low.

5. Concluding remarks

Thyristor series high-voltage soft starter can effectively change the starting characteristics of the motor and reduce the starting current in the application of square torque loads such as compressors. With its superior performance, it can provide comprehensive services for the motor and ensure the entire transmission system. Reliability of operation. While reducing the overall maintenance workload of the system, the thyristor soft starter itself can be maintenance-free, which reduces the overall production cost, has a better return on investment and social benefits, and meets the requirements of the progress of the times, which is an inevitable technological development. trend.