Butterfly valve, which dated back in 1930s, is a common valve type. It is easy to be combined with various driving devices, with good durability and reliability. Its working principle is that the butterfly plate is driven by the valve rod. If the plate is turned 90 °, once opening and closing are completed. Changing the deflection angle of the butterfly plate can control the medium flow.

Figure 1: Various butterfly valves are widely applied in the chemical factory.

According to the Driving Mode

There are mainly divided into electrical butterfly valve, pneumatic butterfly valve, hydraulic butterfly valve, manual butterfly valve.

Electrical butterfly valve: electrical butterfly valve is a kind of electrical valve and adjusting valve. The main connection ways include flange type and wafer type; its main sealing forms include rubber sealing and metal sealing.

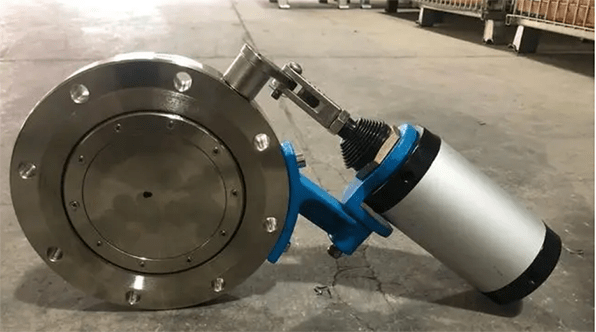

Pneumatic butterfly valve: pneumatic butterfly valve is composed of pneumatic actuator and butterfly valve. It can be divided into stainless steel pneumatic butterfly valve, hard sealing pneumatic butterfly valve, soft sealing pneumatic butterfly valve, and carbon steel pneumatic butterfly valve.

Figure 2: The diagram of pneumatic butterfly valve.

Hydraulic butterfly valve: hydraulic butterfly valve is widely used in blast furnace gas pipe network system in metallurgical industry. In case of dangerous working conditions of the system, the emergency valve closing can be implemented within half seconds to realize the reliable cut-off of the pipeline. This action effectively prevents the backflow of steam and condensate at the tail of the steam turbine, and protect the safety of the steam turbine unit.

Manual butterfly valve: manual butterfly valve, having the characteristics of simple structure, small size, and light weight, consists of several parts. Besides, only rotating 90 degrees can quickly open and close it, and the operation is simple. Meanwhile, the valve has good fluid control characteristic.

According to the Sealing Structure

Central sealing butterfly valve

The structure of this valve features that the valve stem axis, butterfly plate center and body center are in the same position. It has the advantages of simple structure and convenient manufacturing. Common rubber lined butterfly valves fall into this category. The disadvantage is that it is because the butterfly plate and valve seat are always in the state of extrusion and scraping that it has large resistance distance and easy wear.

Single eccentric sealing valve

The structure of this valve features that valve stem axis is eccentric from butterfly plate center, in which upper and lower ends of plate are no longer axis of rotation, which decentralizes and reduces over-extrusion between upper and lower ends of plate and valve seat.

Double eccentric sealing valve

This valve, also called high performance butterfly valve, is mainly applicable to the drainage of water plants, power plants, steel mills, smelting, chemical industry, water source engineering, environmental facilities construction and other systems, especially applicable to the waterway pipeline as the adjusting and closure equipment.

Triple eccentric sealing butterfly valve

Its butterfly plate is installed in diameter direction of pipeline. In the cylindrical channel of the butterfly valve body, the disc-shaped butterfly plate rotates around the axis. The rotation angle is between 0 degree and 90 degrees. When reaching 90 degrees, the valve is fully open.

Figure 3: The structural frame diagram of triple eccentric sealing butterfly valve.

According to the Sealing Surface Material

Soft sealing butterfly valve

Sealing pair is composed of non-metallic soft materials.

Sealing pair is composed of metallic hard materials and non-metallic soft materials.

Hard sealing butterfly valve

Sealing pair is composed of metallic hard materials.

Figure 4: The diagram of hard sealing butterfly valve.

According to the Sealing Form

Compulsory sealing butterfly valve:

Elastic sealing butterfly valve: sealing specific pressure is generated by the elasticity of the valve seat or valve plate when the valve is closed.

Torque sealing valve: sealing specific pressure is generated by torque applied to valve shaft from externals.

Pressurized sealing butterfly valve: sealing specific pressure is generated by the pressure of elastic sealing elements on the valve seat or valve plate.

Automatic sealing butterfly valve: sealing specific pressure is automatically generated by media pressure.

According to the Working Pressure

Vacuum butterfly valve: its working pressure is below to standard atmospheric pressure.

Figure 5: The diagram of G5 series high vacuum butterfly valve.

Low pressure butterfly valve: nominal pressure is lower than 1.6MPa.

Medium pressure butterfly valve: nominal pressure is ranging from 2.5MPa to 6.4 MPa.

High pressure butterfly valve: nominal pressure is ranging from 10.0 MPa to 80.0MPa.

Ultrahigh pressure butterfly valve: nominal pressure is higher than 100MPa.

According to Working Temperature

High temperature butterfly valve:its working temperature is higher than 450 Celsius degrees.

Medium temperature butterfly valve: its working temperature is ranging from 120 Celsius degrees to 450 Celsius degrees.

Normal temperature butterfly valve: its working temperature is ranging from minus 40 Celsius degrees to 120 Celsius degrees.

Low temperature butterfly valve: its working temperature is ranging from minus 100 Celsius degrees to minus 40 Celsius degrees.

Figure 6: The diagram of electrical low temperature butterfly valve.

Ultralow temperature butterfly valve: its working temperature is lower than minus 100 Celsius degrees.

According to the Connection Mode

Wafer butterfly valve

Flange butterfly valve

Lug butterfly valve

Welded butterfly valve

Figure 7: The diagram of flange butterfly valve type.

Related Info

The Structure, Characteristics, and Notices for Use of Butterfly ValveWorking Principle of Butterfly Valve and Emergence of New Butterfly Valve

What is the Gearbox?

The Composition and Working Principle of Reduction Gearbox

Common Problems and Causes of Gearboxes