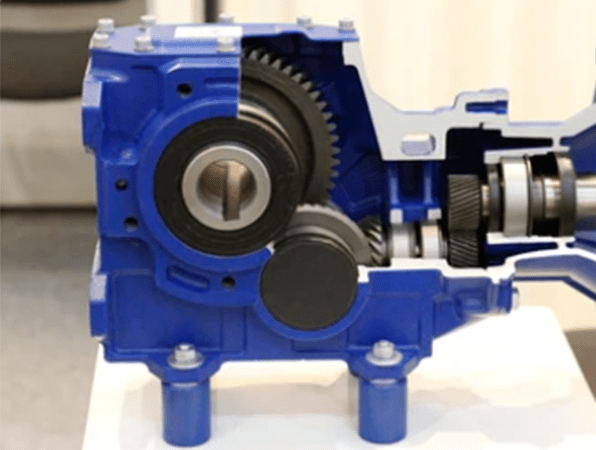

Figure 1: Cross section of the gearbox.

The following will introduce some problems that may occur in the use of gearboxes and the reasons for such problems.

Abnormal Sound of Gearbox

1.Sound caused by bumps in gear teeth surface

Reason: there are bumps in the assembly process. And due to errors in company’s quality test, there are a small number of gearboxes with such problems.

Solution: specific location of abnormal sound can be determined by by calculating the relationship between speed of low-speed shaft and frequency of abnormal sound. According to analysis result, you should carefully look for bumps on related gear teeth surface, and wipe out oil on surface, so as to avoid affecting touching feeling. Bumps mainly exist in two sides of gear crest and gear profile.

2.Abnormal sound caused by bearing itself

When sound drones with fast frequency, gear teeth are normal, and calculated speed ratio proves that there is no problem with gear, it is likely that bearing has some problems.

Reason: dents on inner raceway and roller surface of bearing cause unstable operation, resulting abnormal sound.

Solution: careful inspection should be taken on track and roller of bearing. Replace bearing, if there is a problem.

There are other reasons of abnormal sound, such as excessive circular pitch error of gear itself, friction interference, and rust for long-term non-use.

Figure 2: Damaged gear.

High Oil Temperature in Gearbox

1.Possible faults in air cooler

(1)Air cooler itself has faults, such as short circuit, broken circuit, motor burnout, etc., which cause fan to stop working.

(2)Dust influences heat dissipation of air cooler. Extensive coverage of dust on cooling fin affects heat dissipation of air cooler, resulting in insufficient cooling of the lubricant.

(3)Wiring error of air cooler causes the fan to be reversed, which will cause the wind to be in the opposite direction and affect heat dissipation.

Solution: Check whether the air cooler is faulty, and properly clean the dust on the air cooler.

2.Oil pipe from lubricating system to oil distributor and cooler is connected in reverse.

The two outlets of filter indicate which is to go to the gearbox or to the cooler respectively. When in low temperature, it directly enters into the oil distributor, and when in high temperature, it enters into the cooler.

Solution:If oil pipe is connected in reverse, high temperature oil uncooled by cooler must cause oil temperature to be high. It can be solved by installing oil pipe in accordance with correct requirements.

Figure 3: Air cooler.

3.Faults in pressure valve or temperature control valve of lubricating system.

Under the condition that filter and gearbox oil pipe are connected correctly, when oil temperature exceeds 55 Celsius degree, and flowing oil still exists in the pipe from filter to oil distributor still, it means that there is a problem with temperature control valve of filter.

Solution: you can consult manufacturer or technical department of lubricating system to replace the temperature control valve.

4.Problem with overflow valve

Overflow valve, as a pressure relief element, only works in gearbox with low oil temperature and high pressure. At present, it has been found that there is still flowing oil existing in overflow valve in high oil temperature, so that the amount of cooled oil will be reduced, and part of the oil will be directly returned to the gearbox without cooling, resulting in insufficient overall cooling and high oil temperature.

Solution: If overflow valve opens again in high oil temperature and low pressure, you should contact the manufacturer of lubricating system as soon as possible to address it.

High Temperature of High-speed Shaft Bearing

1.Insufficient oil inflow of bearing

Open the observation cover of the rear box to check the oil output of the bearing. If the oil output is very little, it means that the oil inflow of the bearing is insufficient. Check whether it is the following reasons according to the actual situation, and deal with it accordingly.

(1)Oil inflow hole is too small to get sufficient oil.

(2)Oil inflow pipe of box body and oil inflow ring / tank are dislocated.

(3)Oil hole is clogged with impurities, resulting in reduced oil volume

(4)Oil passage of oil inflow hole is not drilled through

Figure 4: Steel gears and rolling bearing.

2.Small bearing radial clearance

Bearing operation must ensure certain radial clearance. When radial clearance is small, roller and track will become stiff operation, and temperature will rise due to a large amount of heat.

Solution: This situation is relatively rare, and a feeler gauge can be used to detect the radial clearance at the upper end of the bearing.

3.Oil temperature too high or too low

In the case of insufficient cooling, the temperature of the high-speed shaft cannot be effectively reduced under the high oil temperature, resulting in the bearing temperature being too high.

Low oil temperature is prone to too high bearing temperature of high-speed shaft. The viscosity of the lubricating oil is very high at low temperature, and the oil passing through the oil inflow hole will become very little. Moreover, the oil with high viscosity has poor fluidity and thermal conductivity, resulting in higher and higher bearing temperatures, forming a vicious circle.

4.Other reasons accounting for too high bearing temperature: insufficient gear oil injection, bearing damage, friction, etc.

Related Info

What is a Blend Door Actuator?How to Replace a Blend Door Actuator?

What is the Gearbox?

The Composition and Working Principle of Reduction Gearbox

Pros and Cons of Pneumatic, Electric and Hydraulic Actuators