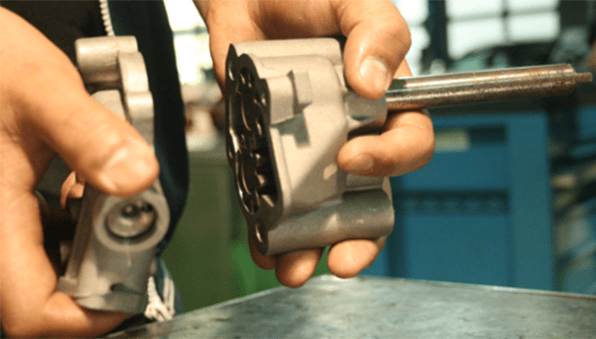

Figure 1: The inside structure of reduction gearbox.

1. Instruction to Select Gearbox Model

When you select Gearbox model, four factors should be given comprehensive consideration.

First, the requirements of working machine on structure and dynamic parameters of the gearbox include dimension, quality, power, speed, transmission ratio, and load characteristics of transmission structure, etc.

Second, the requirements of working machine on performance of gearbox include reliability, working life, noise, vibration, temperature, transmission accuracy, etc.

Third, gearbox is produced with advanced technology, and reasonable price that is accessible and universally interchangeable.

Forth, gear products are low-cost, high-efficient, high-precise, and reliable.

Figure 2: Two different types of gearbox models.

2. Gear Installation Requirements and Notices

Unpacking: unpacking work must be done by sophisticated professional staff with their expertise. Packages of gearbox should be carefully unpacked, including all protective devices during transportation, whether all gearbox spare parts are in good condition should be checked. If there is any problem, please contact the manufacturer as soon as possible.

Remove oil and preservative. Prior to gearbox installation, the first thing to do is to remove residual oil (deposited in box body due to anticorrosion) and antirust from manufacturing surface.

Grease and dust should be removed from the inner hole of planet carrier and surface of main shaft. Shrink disc disassembled from gearbox does not need be separated and be put on lubricating grease in center before installation. If it is in a pretty adverse circumstance, it is necessary to carry clean and spread grease for protection. It will be very easy to install main shaft of planet carrier, if it is heated during installation. It must be done one by one, when you get the screws to turn tightly.

High-speed shaft, tube shaft, and planet carrier of gearbox are not allowed to be knocked or hit during the installation, and external axial force and radical force cannot be exerted on these parts without the consent of company, because these actions are likely to cause gearbox damage.

Lubricate: if lubricating system of gearbox is provided separately, it must be checked whether lubricating system is installed and pipeline connection is in good condition before adding lubricant. Meanwhile, please do not mix other matters into gearbox when adding lubricant.

Figure 3: A sophisticated professional staff unpacks the gearbox.

3. Gearbox Maintenance

3.1 Change Oil

After its first six month’s operation, you should change the oil, and rinse out gearbox. Generally, lubricant should be replaced every year, at least not more than 15 months. After six month’s operation, check the oil quality as follows, and change it if one of the following appears:

Check whether there are sediments at the bottom of box body.

Check whether there are water or emulsion.

Check the viscosity, and if difference exceeds 20%, compared with original one, it proves that the oil is no longer effective.

Check insoluble matter, and if it exceeds 0.2%, the oil should be changed or filtered.

Test for demulsification capacity is conducted to check whether the oil is deterioration.

At the beginning of operation, please pay attention to observe whether there are obvious changes. If so, pinpoint the reason and cope with in time.

3.2 Take Operation and Maintenance Record

Working load, speed, lubricant temperature, and bearing temperature should be recorded every day. If there is any abnormal change, it should be analyzed and studied in time to find the problem as soon as possible.

3.3 Maintenance and Check

After its 48-hour’s operation, all gearbox fasteners should be checked once for looseness. Recheck the axis alignment. Schedule regular inspections in the future.

Ventilation hood on gearbox should be rinsed out once a year.

3.4 Routine Inspection

Every day: check for oil leakage, abnormal vibration, noise and bearing temperature.

Every week: check for rinse.

Every month: check whether the foundation bolts are loose, supplement lubricant in time, and check the working conditions of each instrument.

Every six months:

Conduct laboratory analysis of oil quality. If the oil quality is up to standard, it is suggested to drain the oil from the lubricating system, carry out precipitation filtration, and reuse it. If the oil quality has deteriorated, the recommendation is to drain the oil and inject new oil.

Check the alignment of and wear of coupling.

Check conditions of gear teeth contact and bearing.

When it is not used for a long time, the gearbox should be run 10 minutes every week, otherwise, it should be oil-sealed according to the long-term storage method.

Figure 4: Regular maintenance of gearbox manipulated by staff with intimated knowledge of it.

4. Gearbox Rinsing Notice

4.1 Disassembly

Clean the ground around the gearbox before disassembly. Prepare wooden blocks or backing plate to place spare parts, so as not to damage the surface of the parts.

Pay attention to assembly marks of the spare parts.

4.2 Reassembly

Rinse out spare parts, carefully check for damage of parts, and replace if necessary. It is necessary to replace damaged bolts, nuts, and washers.

Pay attention to original assembly marks.

Apply sealant on the split surface and end cap to avoid oil leakage.

After assembly, gearbox shall be put into operation with help of hand drive without any abnormal or jamming actions.

Figure 5: A staff is rinsing gearbox with powerful water gun.

Related Info

Installation and Maintenance of GearboxHow to Replace a Blend Door Actuator?

What is the Gearbox?

The Composition and Working Principle of Reduction Gearbox

Common Problems and Causes of Gearboxes