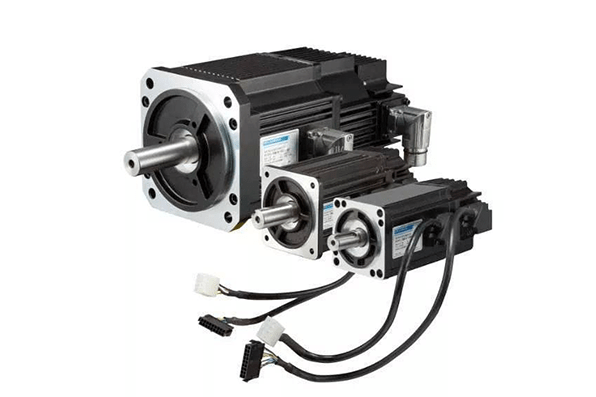

Servo drive is a commonly used motor control device, commonly used in various automated production equipment and robot control systems. Servo drive failure will cause the motor to fail to operate normally, thus affecting the normal operation of the entire automation system.

Therefore, we need to understand common servo drive faults and their solutions in order to troubleshoot faults in time and ensure the stability and reliability of the equipment. The following are common servo drive failures and their solutions.

1. Servo Drives: Common Fault Types and Solutions

1.1 Power Supply Failure

Servo drive power supply failure causes the servo drive to fail to work properly. Power supply failure may be caused by problems with the power supply itself or problems with the external factors.

Common servo drive power supply failures include:

1. Abnormal power supply voltage: It means that the voltage output by the power supply is unstable or exceeds the acceptable range of the servo drive. This may cause the servo drive to fail to work properly or damage the servo drive.

Solution: Check whether the voltage output by the power supply meets the requirements of the servo drive. You can use a multimeter or oscilloscope to detect it. If the voltage is unstable, consider replacing the power supply or using a stabilized power supply.

2. Power supply overload or overheating: When the servo drive workload is too heavy or the ambient temperature is too high, the power supply may be overloaded or overheated. This may cause the power supply to be damaged or the servo drive to not function properly.

Solution: Check whether the workload of the servo drive exceeds the rated load range of the power supply. You can consider increasing the power supply or using a more efficient cooling device to reduce the ambient temperature.

3. Incorrect power supply wiring: It may cause the servo drive to fail to work properly or damage the servo drive. For example, wiring errors may cause the power supply to output too high or too low a voltage, or prevent the power supply from functioning properly.

Solution: Check whether the power wiring is connected correctly and firmly. If the wiring is incorrect, the power supply should be reconnected.

4. Power supply failure may be caused by problems with the power supply itself. For example, power supply damage, short circuit, open circuit and other problems may cause the servo drive to fail to work properly.

Solution: Check whether the power supply is damaged. You can use a multimeter or replace the power supply for detection. If the power supply is damaged, it should be replaced.

5.Power line interference: It may cause the voltage output of the power supply to be unstable or generate noise, which may interfere with the normal operation of the servo drive.

Solution: Install power line filters or use anti-interference power lines and other measures.

1.2 Drive Failure

This type of failure is mainly caused by component damage, overheating or overload inside the drive. The drive is a device that amplifies the control signal and outputs it to the motor. If it has a failure, it will cause problems such as failure to start, abnormal speed or alarm.

Troubleshooting methods include checking and replacing damaged components, reducing temperature or load, resetting or removing alarms, etc.

Specific methods:

1. Regularly check the operating status and performance of the drive so that faults can be discovered in time and necessary measures can be taken.

2. Using high-quality and reliable drives can reduce the occurrence of failures.

3. Proper use and maintenance of drives can extend the service life of the drive and reduce the failures.

4. Clean the surface and interior of the drive regularly to avoid dust and other debris from entering.

5. Avoid overheating the drive, and do not use it in a poorly ventilated environment.

6. Avoid voltage fluctuations and electrical interference, such as using a stable power supply and preventing the drive from being close to other electronic devices.

7. Replace aging drive components in time, such as capacitors, resistors, etc.

1.3 Motor Failure

Motor failure is one of the common problems that servo drives may encounter, and may be caused by a variety of reasons, such as motor coil short circuit, open circuit, overload, overheating, damage, etc.

The following are some common motor faults and corresponding solutions:

Short circuit in motor coil: usually caused by damaged or worn insulation in the coil. Solutions include replacing the insulation material or replacing the motor.

Open circuit in motor coil: usually caused by broken or corroded wires in the coil. Solutions include replacing wires or replacing the motor.

Motor overload: It may be caused by excessive load or unreasonable motor design. Solutions include reducing the load or replacing the motor with a suitable one.

Motor overheating: It may be caused by overheating of the use environment or unreasonable motor design. Treatment methods include improving the use environment or replacing it with a suitable motor.

1.4 Encoder Failure

Encoder failure is one of the common failures in servo drives. Encoders are usually used to convert the motor's position information into digital signals and transmit them to the controller to control the motor's position and speed. If the encoder fails, the controller will not be able to accurately obtain the position information of the motor, causing the servo drive to be unable to correctly control the motor movement.

The following are some possible causes of encoder failure and corresponding solutions:

Encoder damage: It may be caused by excessive use, mechanical impact or electrical interference. Solutions include replacing the encoder or performing repairs.

Encoder connection failure: It may be caused by loose or damaged connection lines. Solutions include checking and replacing connecting lines.

Encoder position deviation: It may be caused by incorrect installation or mechanical impact. Solutions include reinstalling the encoder or making adjustments.

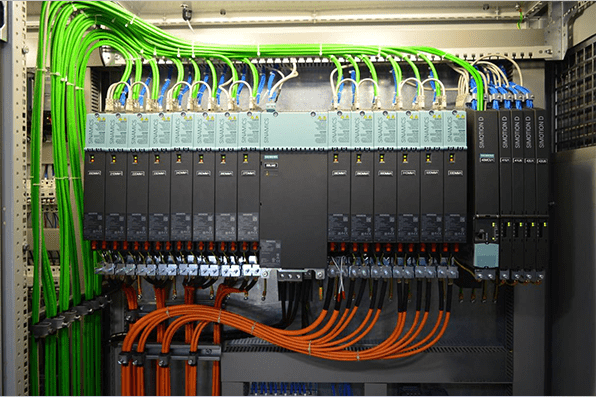

1.5 Control System Failure

This type of failure is mainly caused by problems with the software or hardware of the control system. The control system is a type of device used to send control signals and receive feedback signals. If there is a problem, it will lead to failure of communication, instruction errors, or loss of control.

Troubleshooting methods include checking and updating software, replacing or repairing hardware, resetting or debugging parameters, etc.

1.6 Signal Interference

Signal interference may cause the servo drive to be unable to receive correct instructions or sensor feedback information. Signal interference can be caused by electromagnetic fields around the device or other sources of interference.

Signal interference is a common cause of servo drive failures, especially in industrial environments. Since there are a large number of electronic and electrical equipment in modern industrial environments, the electromagnetic fields generated by these devices may interfere with the normal operation of the servo drive.

Methods to solve the signal interference are as follows:

1. Install shielded cables: When using a servo drive, you can use shielded cables to separate the signals inside the cables from the external environment to avoid interference from external electromagnetic fields. Shielded cables usually consist of a metal mesh or copper foil kit.

2. Isolate servo drive: It can avoid electromagnetic field interference caused by other equipment to the servo drive. You can isolate the servo drive by using isolation plates or by placing it in a separate metal box.

3. Use electromagnetic shielding materials: Electromagnetic shielding materials can effectively prevent the spread and interference of electromagnetic waves. Electromagnetic shielding materials can be used on walls, ceilings, floors, etc. around the servo drive to reduce interference to it.

4. Adjust cable location and wiring: Placing cables in appropriate locations can reduce interference. You can keep cables and wiring of the servo drive separate from those of other equipment.

5. Choose the right servo drive: When purchasing a servo drive, you should choose products with anti-interference capabilities. These products usually use advanced circuit design and electromagnetic shielding materials to reduce the impact of interference.