Do you know the reasons for the attenuation of the cooling capacity of the screw refrigeration unit?

Lithium bromide absorption refrigeration units are a type of refrigeration equipment that will inevitably produce cold capacity attenuation. The annual attenuation is about 10%, and the working life is basically 6 to 7 years. Screw compression refrigeration units will also produce cooling capacity attenuation, but it is not inevitable. The attenuation rate is related to the design, manufacture, use and maintenance of the unit.

This time the editor will take a look at how the cooling capacity attenuation of the screw refrigeration unit is produced and how to reduce its attenuation.

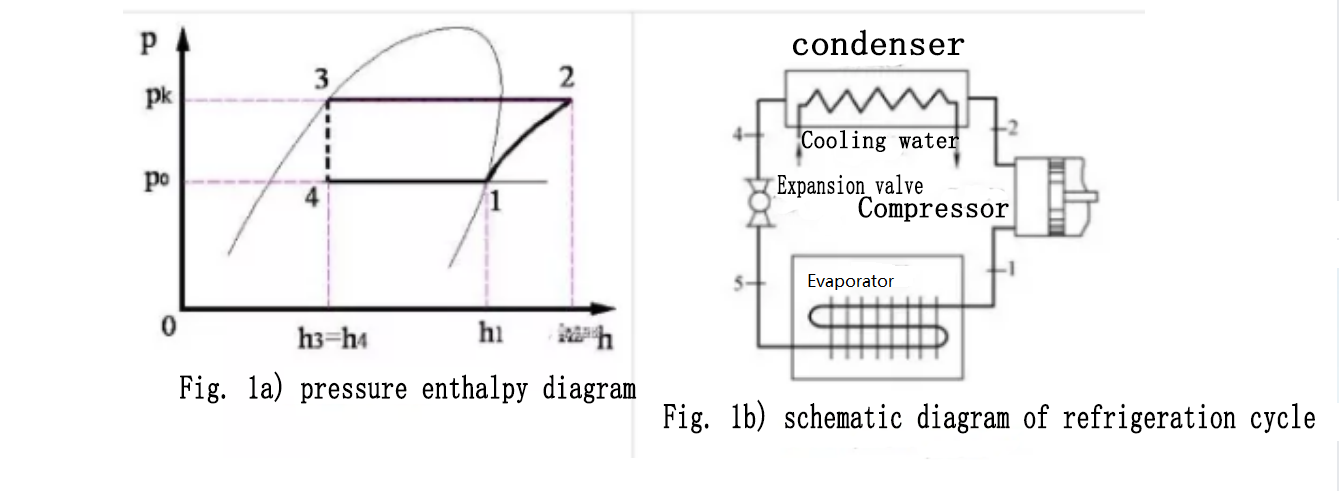

First, let's look at the calculation formula of refrigeration capacity in combination with the pressure enthalpy diagram:

Q=m·Δh Equation 1

Q=S·K·ΔT Equation 2

In the formula: Q —— cooling capacity

M —— refrigerant mass flow

Δh —— h1- h4, the enthalpy difference between the inlet and outlet of the evaporator

S —— Heat transfer area of evaporator

K —— total heat transfer coefficient of evaporator

ΔT —— Average temperature difference of heat transfer of evaporator

From the calculation formula, for a given refrigeration unit, assuming the working conditions remain unchanged, we can see that the cooling capacity is affected by the refrigerant flow rate, the enthalpy difference between the inlet and outlet of the evaporator, and the heat transfer coefficient of the evaporator.

One, look at the refrigerant flow rate, what factors will reduce the refrigerant flow rate.

1, compressor

After a long time operation of the screw compressor, the mechanical wear of the rotor and the tandem shaft will increase the compressor clearance and increase the leakage rate, which will reduce the refrigerant flow and the cold capacity. In order to reduce the mechanical wear of the rotor, materials with better wear resistance and rigidity should be selected as much as possible, and the machining accuracy should be improved to ensure the installation accuracy.

2, refrigerant leakage agent

The leakage of refrigerant will directly reduce the refrigerant. The mixing of air into the unit will increase the condensing pressure, thereby increasing the enthalpy value of the refrigerant entering the evaporator, that is, reducing the enthalpy difference between the inlet and outlet of the evaporator.

Improve system sealing to solve this problem.

3, the throttle valve is dirty

The throttle valve is dirty to reduce the flow of refrigerant passing through.

Add a filter before the throttle valve to reduce the throttle valve's dirty clogging.

2. Factors affecting the enthalpy difference between the inlet and outlet of the evaporator.

Poor cooling water quality will cause fouling of the heat exchange tube. If the cooling water flow rate is low, it will accelerate the fouling. Fouling leads to a decrease in the heat transfer coefficient of the condenser, a decrease in heat exchange capacity, and an increase in the condensing pressure, which makes the enthalpy value of the refrigerant entering the evaporator inlet increase, thereby reducing the enthalpy difference between the inlet and outlet of the evaporator.

Therefore, in the design process of the condenser, a suitable fouling factor should be reserved according to the actual situation to ensure the heat exchange demand after a period of operation. The design flow rate should not be too low. In operation and management, attention should be paid to the quality of cooling water, and the poor water quality should be treated to improve water quality.

2. Air is mixed into the system

Air mixed into the system will increase the condensation pressure and reduce the enthalpy difference between the inlet and outlet of the evaporator.

Do a good job of vacuuming the system to ensure the tightness of the system, or adding an air remover can improve this problem.

3, non-azeotropic refrigerant unit

For 4 series non-azeotropic mixed refrigerants such as R404A and R407C, the evaporation temperature of each component is different. Even if the refrigeration leaks slightly, it will change the refrigerant composition and the physical properties of the refrigerant, that is, the enthalpy of the refrigerant at the inlet and outlet of the evaporator. The difference will change.

Large refrigeration systems avoid the use of non-azeotropic refrigerants. The use of non-azeotropic refrigerants must ensure the tightness of the refrigeration system.

3. Change of heat transfer coefficient of evaporator

1. Lubricating oil is attached to the heat exchange tube

Generally speaking, the high-temperature side lubricating oil and refrigerant have better mutual solubility, so the lubricating oil will be taken away by the refrigerant. The low temperature side refrigerant and lubricating oil are not mutually miscible, so the refrigerant stays on the evaporation side. If the oil separation effect is not good, and there is no oil return device, more and more oil will collect at the heat exchange tube of the evaporator, which will reduce the heat exchange capacity of the evaporator, thereby reducing the cooling capacity.

Using an oil separator with higher oil separation efficiency, or adding an oil return device can improve this phenomenon.

2, evaporator heat exchange tube fouling

The fouling of the heat exchange tube will reduce the heat transfer coefficient of the evaporator, resulting in a decrease in the cooling capacity. Therefore, it is necessary to pay attention to the condition of the cooled medium to ensure its cleanliness and reduce the fouling of the heat exchange tube.