Figure 1: KaiShan air compressor.

Air compressor oil is mainly used for the lubrication of the moving parts in the compressor cylinder and the exhaust valve, and plays the role of anti-rust, anti-corrosion, sealing, sound reduction and cooling.

If the air compressor is always in the environment of high pressure, high temperature and where condensed water exists, the air compressor oil should have excellent high temperature oxidation stability, low carbon deposition tendency, suitable viscosity and temperature performance, good oil-water separability, anti-rust and anti-corrosion, etc.

1. Factors Affecting the Service Life of Compressor Oil

1.1 Moisture and Dust Content

The service life of lubricating oil mainly depends on the operating environment of the air compressor, and moisture and dust content in the air are key factors. The filtration accuracy of the oil filter is generally not less than 15 microns, that is to say, the dust less than 15 microns will go into the circulation of lubricating oil. When the dust concentration below 15 microns is too large, the oil must be changed.

1.2 Metal Corrosion

Moisture in the compressed air causes the lubricating oil to emulsify and lose its lubricating effect. In addition, metal corrosion caused by moisture causes a large number of rusts less than 15 microns to circulate with lubricating oil. Oil change is an important means to maintain the life of the air compressor.

Figure 2: Working principle diagram of screw air compressor system.

Air flow: 1.Air intake filter 2.Air intake valve 3.Compression element 4.Non return valve 5.Air/oil separator vessel 6.Minimum pressure valve 7.After-cooler 9.Water separator with drain

Oil flow: 11.Oil 12.Oil cooler 13.Thermostatic bypass valve 14.Oil filter 15.Oil stop valve

1.3 Oxidation

During the use of compressor oil, it will be affected by heating, oxidation, high-speed shearing, dust pollution and harmful gases. Oxygen reacts with the hydrocarbons in the lubricating oil, causing the oil to slowly oxidize, turn black, and increase the viscosity.

In the end, it may be so serious that the oxides cannot be dissolved in the oil, but are deposited somewhere in the system as a brown slime layer, which is easy to block the control oil passage in the component, which will increase the friction of the ball bearing and the valve core, and affect the normal operation of the system.

1.4 Corrosion and Acidification

Oxidation also produces corrosion and acidification. The oxidation process is slow at beginning, and the accumulated sediment and acid value increase, and the viscosity increases. When it reaches a certain level, the oil should be changed. Otherwise, the oxidation will continue, its rate will gradually increase, and the viscosity will increase accordingly, resulting in an increase in the oil temperature when working.

As the oxidation continues to intensify, the viscosity of the compressor oil will tend to increase significantly. When the rate of oxidation changes from a linear to a power curve, the viscosity rises faster, and the result people may not want to see will appear.

2. Guide to Replacing Compressor Oil

Tools you need:

●A container for catching the old oil

●Funnel

●Wrench

●Suitable new compressor oil

●Filter element (maybe needed)

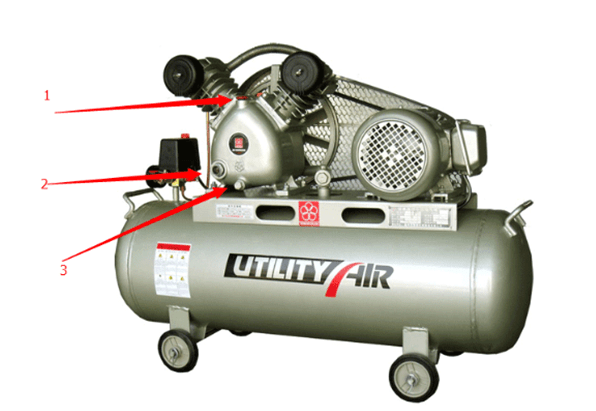

Figure 3: Utility air compressor.

1. Oil inlet 2. Sight glass 3. Oil outlet

1. Start the air compressor and let it run for about 5 minutes, and stop it when the oil temperature rises to about 50°C and the viscosity of the lubricating oil drops significantly.

2. Pay attention to observe the internal pressure of the oil sump. When the pressure is around 0.1Mpa, open the oil drain valve at the bottom of the oil sump and use a receptacle to catch the old oil. Note that the oil drain valve must be opened slowly, otherwise it is easy to cause the lubricating oil to splash.

3. After the lubricating oil is drained completely (when the lubricating oil is discharged in drops, it means that it has been initially drained), close the oil drain valve. Unscrew the oil filter element of the air compressor, drain the lubricating oil in each pipeline, and it is recommended to replace the oil filter at this time.

4. Insert the funnel at the oil inlet to prevent the lubricating oil from leaking out when it is poured.

5. Add new oil until the oil level is within the range of the scale mark (sight glass), and tighten the screw plug of the oil filler. So far the whole oil change process is basically over.

Figure 4: Oil the air compressor through the funnel.

However, although the oil change process is over, our work is not over yet. We must carefully check the oil sump and other parts of the air compressor to see if there is any leakage. After confirming that everything is normal, the work is completed

3. How to Get Better Oil Change Effect?

When changing the oil for the air compressor, if the dirty oil is not drained completely, the newly added compressor oil will be polluted, which will accelerate oxidation, and cut half of the life of the newly added compressor oil.

In order to achieve a good oil change effect, the following countermeasures are available:

Add 3-5% cleaning agent to the old oil of the air compressor, and after 6-24 hours of operation under normal working conditions, drain all the oil in the system. After replacing the oil filter and oil-air separator components, add new compressor oil and start the compressor to run normally.

If the oil sludge or carbon deposits in the system, brought by the use of mineral oil or oil with poor quality, has not been cleaned for a long time, the cleaning time can be extended appropriately, generally 2 to 3 days. If a large amount of oil sludge, carbon deposits or colloids appear during the cleaning period, the filter will be blocked, which may cause the system to trip. At that time, it is needed to replace the filter and clean the system.

Figure 5: Parts of an air compressor unit.

When changing the oil and gas separator components, carefully clean the oil and gas separator housing. Depending on the situation, determine whether the oil cooler needs to be cleaned. If it needs to be cleaned, change the oil after cleaning.

After draining the old oil from the compressor, add an appropriate amount of new oil. Run it at low pressure for 5-10 minutes, and drain the oil. Keep the released oil properly (it is better to store it in a 5-gallon pure water plastic bucket, and the sediment can be removed when it is used next time), and it can be used for the next oil change.

Repeat the previous step, add new oil, run the compressor and then drain the oil. Blow the oil pipeline (including the oil cooler) and the oil-gas separator with compressed air or bottled nitrogen, and then add new compressor oil after blowing cleaning.

After adding new oil, add 0.5% of the new oil weight SL anti-wear repair agent, which can not only prolong the life of the bearing, but also double the life of the air compressor oil because the SL anti-wear repair agent contains antioxidants.

If needed, users can contact a high-level professional lubricating oil service provider and entrust them to clean the oil circuit of the air compressor and change the oil.

4. What Kind of Lubricant Do You Use for an Air Compressor?

Figure 6: Air compressor lubricating oil.

Air compressor lubricating oil selection method:

1. The air compressor manual indicates the type of lubricating oil can be used. Replace it according to requirements or purchase directly from the equipment manufacturer.

2. Choose lubricating oil according to working conditions. If the working environment of the air compressor is very harsh, it is easy to generate carbon deposits, and the oil needs to be replaced frequently, it is recommended to use mineral oil. Mineral oil itself has a short service life and needs replacing frequently.

Relative to the normal working environment, it is recommended to choose synthetic or semi-synthetic air compressor lubricants. Compared with mineral lubricating oil that needs to be replaced every 2000 hours, the replacement cycle of semi-synthetic and fully synthetic is generally 4000-8000 hours.

3. Choose lubricating oil according to the cost of use, and choosing fully synthetic lubricating oil is more cost-effective. Synthetic oil remains more viscous at high temperatures than mineral oils, while at low temperatures it becomes less viscous than mineral oil and has fewer cold start problems.

Mineral oil contains more volatile components and consumes more oil, while full synthetic oil does not have this problem.

Synthetic air compressor oil lasts longer, while reducing oil filter, oil separator and bearing replacement times. That is to say, it reduces the cost of air compressor consumables and saves labor costs.

Conclusion: If the air compressor works in a poor environment, the cost of using mineral lubricating oil is lower. Synthetic lubricating oil can be used if the working environment is good.

5. How Much Oil Do I Put in My Air Compressor?

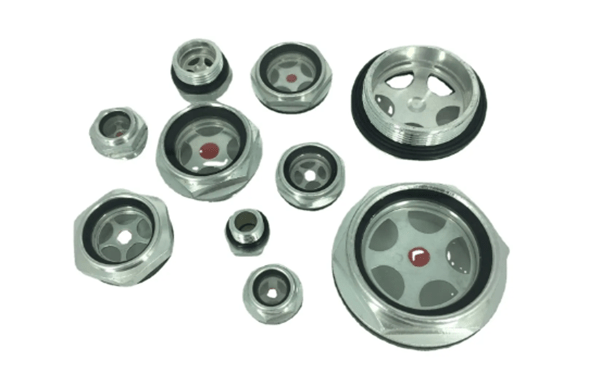

Before answering this question, one point should be emphasized, that is, the air compressor must use its professional air compressor lubricating oil, and do not use machine oil/ motor oil at will. The oil level should be at the upper middle position of the sight glass.

Figure 7: Air compressor sight glasses.

6. When Should I Change My Air Compressor Oil?

The service life of air compressor oil is mostly determined by its own base oil type.

The service cycle set by the air compressor oil manufacturer is generally according to the standard working conditions of the air compressor (clean air, operating temperature within 95 degrees, normal operation of the air compressor, etc.), and the harsh working conditions will shorten the oil life.

The replacement cycle of air compressor oil is divided into 3 situations:

1. Mineral oil should replaced every 3 to 4 months;

2. Semi-synthetic oil should be replaced every 6 to 8 months;

3. Fully synthetic oil is replaced every 10 to 11 months.

In addition, the air compressor oil should be changed in advance in the following situations:

1. There are many air impurities in the place where the air compressor is located;

2. The air contains corrosive substances;

3. The ambient temperature of the compressor room is high;

4. There is a lot of dust in the air.

Related Info

Diagnosis and Troubleshooting of Refrigeration Compressor Failure13 Reasons Why Your Samsung Refrigerator Not Cooling (The Latest Version)

How Refrigerator Compressor Works (Structure Diagram, Working Principle Diagram)

How a Refrigeration Compressor Works

4 Types of Safety Protection for Refrigeration Compressors (9 Common Protection Devices for Refrigeration Compressors)