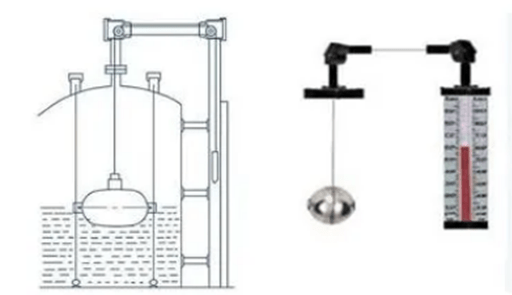

Figure 1: Different float level merers.

Float level meter is a continuous liquid level measuring instrument with simple installation and reliable operation. It is widely used in chemical industry, metallurgy, electric power, papermaking, food, industrial sewage treatment and other industries. It is also used to measure the liquid level of media in water tower, pool, water tank, sump and industrial tank.

In order to ensure that the float level meter can work normally and reliably, the correct installation of it is very important. So, how to install the float level gauge correctly?

Specific Steps

Generally, the following steps should be followed when installing the float level meter :

1.In order to prevent the floating ball from sliding or impacting on the sealing pipe at high speed during transportation causing the measuring belt to fall out, the instrument should be fixed at the bottom of the sealing pipe with clamps before leaving the factory. And the magnetic steel should be at the top of the sealing pipe. Before installation and use, users should first remove the clamp, raise the floating ball to the top of the sealing pipe, and then gently move the floating ball down. And the pointer should rotate accordingly.

2.Before installation, please confirm that there are no ferromagnetic impurities in the measured liquid body and around the level meter. And the specific gravity of the medium should be greater than that of the floating ball, otherwise the normal operation of the level meter will be affected.

Figure 2: Float level meter and its installation diagram.

3. The instrument must be installed vertically at the position where the floating ball is not obstructed when moving up and down, so as to ensure that the floating ball can move up and down freely in the main pipe.

4. The installation position of the float level meter should be far away from the liquid inlet, otherwise the floating ball will easily fluctuate due to the liquid injection at the inlet resulting in misoperation.

5. For level meters with measuring range more than 3.5m, support ears should be installed at the bottom of the guide rod to strengthen the guide rod and make it more stable;

6. The zero point and full range position of the level meter have generally been set according to the user's needs when leaving the factory. Please do not reset them at will to avoid abnormal detection.

7. When the float level meter is used for a period of time, if the float is difficult to float or the float is insensitive to move, it is caused by the iron filings or other dirt on the float guide rod hole caused by the magnetism of the float. At this time, the medium should be drained first, then the float should be taken out. And the iron filings or other dirt on the float should be removed. Then it will be reinstalled.

Related Info

What is an expansion valveHow to select the thermal expansion valve

6 Things about your wine cooler notworking

how to select the chiller and what should be paid attention to when using the evaporator