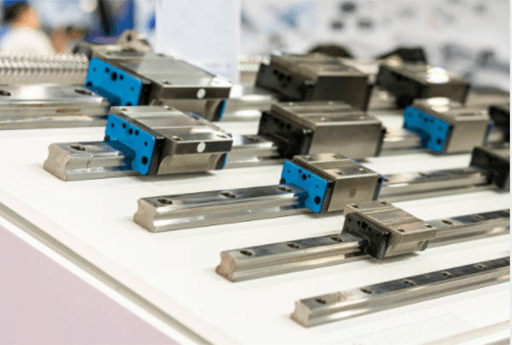

Figure 1: Linear guideways.

The linear guideway is a precision part, which has the advantages of high wear resistance, long service life, high speed and high acceleration, simple and convenient installation, high guidance accuracy, mute and energy saving.

Even if the high-performance linear guide is used, it can not achieve the expected performance effect and it is easy to damage the linear guide when it is used in an incorrect way.

1. How to Maintain It

When using linear guide rail, pay attention to the following matters:

1.1 Prevent Corrosion

When directly taking the linear guideway by hand, fully wash the sweat from your hands and apply high-quality mineral oil before operation. Pay special attention to rust prevention in rainy season and summer. For linear motion system, it is necessary to select materials that can meet the requirements of service environment. In order to be used in environments requiring corrosion resistance, some linear motion systems can use martensitic stainless steel.

1.2 Keep the Environment Clean

Figure 2: Clean linear guideways on a clean platform.

Keep the linear guide rail and its surrounding environment clean. Because even the small dust invisible to the naked eye enters the guideway, it will increase the wear, vibration and noise of the guideway.

If dust and other foreign matters enter the linear motion system, it will lead to abnormal wear and shorten the service life of the guideway. Therefore, foreign matters must be prevented from entering the system. So, it is necessary to select the sealing device or dust-proof device that meets the service environmental conditions when it is expected that dust and other foreign matters may enter.

1.3 Be Careful During Installation

The linear guideway shall be used and installed carefully. It is not allowed to press strongly, directly knock the guideway with a hammer. It is also unallowed to transfer pressure through the rolling body.

1.4 Using Appropriate Installation Tools

Figure 3: Some tools for installation

Proper and accurate installation tools shall be used for the linear guideway, special tools shall be used as far as possible. And things such as cloth and short fiber shall be avoided.

1.5 Lubrication

Good lubrication function must be provided when linear motion system is used. If it is used without lubrication, the rolling part of the guideway will wear faster, so its service life will be shortened.

Generally, the sliding block should be lubricated with oil before installation. The method is very simple: inject it through the nozzle with an oil gun for at least three times after the guide rail is installed. After the first injection, go forward for a section and then inject it for the second time, and so on. When refueling, different greases shall be selected according to the use including guideway oil, guideway dual-purpose oil and grease. Some machines used in harsh environment have large guide rails and simple structure. Their linear guideways are designed to be lubricated with grease, and most of them use manual extrusion with grease gun to supply oil.

Then it is the oil injection by users after the equipment leaves the factory. Generally, it needs to be injected once for 500 kilometers. In fact, it is very simple to inject oil through the nozzle with an oil gun.

Figure 4: A linear guideway after lubricated.

1.6 Clean the Guideway

As one of the core components of the equipment, the linear guideway is required to have high guiding accuracy and good motion stability in order to ensure the high machining accuracy of the machine. During the operation of the equipment, the processed parts will produce a large amount of corrosive dust and smoke during processing. These fumes and dust are deposited on the surface of the guideway and linear shaft for a long time, which will have a great impact on the machining accuracy of the equipment form corrosion spots on the surface of guideway linear shaft and shorten the service life of the equipment.

Therefore, the linear guideway needs to be cleaned regularly. Articles with strong acid and alkali shall not be used for cleaning. It will cause great damage to the linear guideway and make it easier to rust, so as to speed up the damage. Clean the linear guideway with gasoline or kerosene as much as possible. After that, it shall be dried thoroughly, and then the surface of the linear guideway shall be coated with engine oil or special antirust oil, so that a layer of maintenance film will be formed on its surface, which can prevent contact with water in the air, so as to basically avoid rust.

2. Summary

The maintenance of linear guideway includes the maintenance before and the maintenance after installation. In order to make the machine work normally and stably and ensure the processing quality of products, the daily maintenance of guideway and linear shaft should be done carefully.

Related Info

How to select linear guidewaysHow to select the thermal expansion valve

Dry mode vs cool mode on your ac