Figure 1: A compressor is being tested by a multimeter.

Refrigerators are very common in our daily life. Most people know how to use refrigerators, but they do not know the relevant knowledge. Sometimes the refrigerator is out of order, but users do not know how to solve it.

Today's home appliances, refrigerators, and air conditioners all have compressors, which are their core components. Once the compressor fails, these appliances will strike! To test the quality of the compressor, you need to master some basic knowledge, such as the judgment of the quality of the hermetic compressor?

Today, we will let you understand how to test the refrigerator compressor.

Test Compressor by Multimeter

First, you should measure the compressor winding.

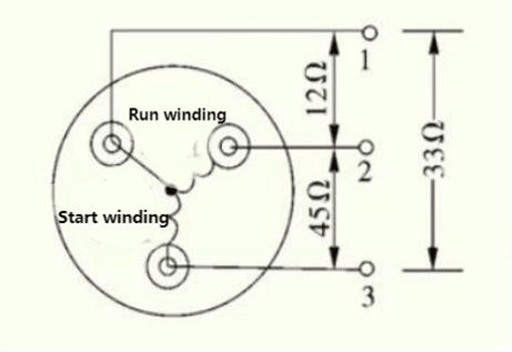

Figure 2: The wiring diagram of the hermetic compressor.

You should use a multimeter to measure the resistance between 1 and 2 terminals, 1 and 3 terminals, 2 and 3 terminals. Under normal conditions, the measured resistance is 12Ω, 33Ω and 45Ω accordingly.

The running winding resistance is minimum, the starting winding is greater than the running winding but smaller than the maximum resistance, and the high resistance is the sum of the running winding plus the starting winding.

How to Judge it

When the measurement resistance value is infinite, it is the open circuit. When the measurement value is very small or close to zero, it is a short circuit. Maximum sum of the running winding and the starting winding indicates that there is an inter-turn short circuit between the windings.

Figure 3: A multimeter.

Second, you should measure the insulation resistance of the compressor motor. If the measured insulation resistance is less than 2MΩ, it would indicate that there is a leakage of the motor winding and shell, which is not suitable for use.

Third, you should check the suction and exhaust performance of the compressor. You start by welding the suction and exhaust pipes on the compressor, then energizing the compressor and running it. At this point you use your hands to plug the exhaust port, if you feel it is difficult, it means that the compressor exhaust performance is better.

Then you release the exhaust port and gently block the suction port. You will feel a strong inward suction force and the compressor noise will be reduced. This indicates that the compressor exhaust and suction performance is good. If the circumstance does not match the preceding description, the compressor exhaust and suction performance is poor.

Figure 4: The compressor port.

Test Compressor by Sound

Normal Sound

* Sounds like Pitter-Patter

After the compressor has run for a few minutes or stopped for a while, you may hear “pitter-patter". You should determine where this sound is made. If it is located in the back of the refrigerator, generally it is made by the copper pipe of the condenser or the heat sink of shutters, due to the effect of heat expanding and cold contracting.

And if the noise is from the upper refrigerator, it will be due to the upper evaporator whose temperature changes frequently, and the thin ice that has been frozen together in the lifting part is pulled and broken, resulting in a sound like “pitter-patter". Both of these sounds are normal.

* Sounds like Dang-Dang

When the compressor in operation stops suddenly, it will produce this kind of sound. Sometimes it occurs once, sometimes twice, and the sound is louder. The sound comes from the compressor inside.

The reason is that there are three springs in the compressor hanging the cylinder and stator, used to shock. When the compressor stops working, there will be a resistance. Because of the effect of the spring, the cylinder swings to both sides, producing the metal banging sound that is also normal.

Abnormal Sound

* Crash

When the compressor is running, the metal collision sound is emitted in the machine. This sound is caused by the high-pressure noise elimination and fracture in the compressor. Chances are you'll encounter this situation in your use of the refrigerator. You need to open the casing and replace the high pressure muffler or weld the break.

* Boom

During the operation of the compressor, it makes an abnormal sound “boom". The reason may be that a hanging spring in the machine is broken or dislocated, causing the cylinder to collide with the compressor casing. This kind of sound needs you to cut the casing, check the reason for the lifting spring dislocation, or the reason for the break, to troubleshoot.

Related Info

How to Tell if Your Refrigerator Compressor is BadIs It Necessary to Replace Your Refrigerator Compressor?