Precautions for using R410A refrigerant in air conditioner

1. Refrigeration oil:

The types of refrigerating machine oil (lubricating oil) are roughly divided into mineral oil and synthetic oil according to the use of refrigerant. The lubricating oil of R22 refrigerant currently used is basically mineral oil. R410A refrigerant uses synthetic oil.

Synthetic oil can be divided into: AB, PVE, PPE, PAG, POE, PC, etc. R410A refrigerant currently uses two types of refrigeration oil for compressors in most companies: PVE (ether) and POE (ester).

2. Pressure characteristics:

R410A refrigerant is about 1.6 times the pressure of R22 refrigerant. Due to high pressure, special tools and installation materials for R410A refrigerant must be used.

Saturated gas pressure comparison between R410A and R22 (unit: MPa):

Refrigerant temperature and pressure gauge, as shown below:

Three, use matters needing attention:

1. The pressure of R410A is about 1.6 times higher than that of R22 refrigerant. When installing R410A refrigerant air conditioner, use R410A special tools and materials, pay attention to safe operation.

2. The mixing of non-condensable gases such as air will cause abnormal high pressure in the refrigerant circulation pipeline, which is the main cause of rupture and cracks in the circulation pipeline.

3. When installing one-to-multiple air conditioners, because the amount of enclosed refrigerant is relatively large, especially in small rooms, even if the refrigerant leaks, its concentration cannot exceed the specified value. Otherwise, it will cause hypoxia.

4. In household air conditioners using R410A refrigerant, refrigerants other than R410A must not be used. In air conditioners that use R22 refrigerant, R410A refrigerant must not be used.

5. Since R410A is an almost azeotropic mixed refrigerant, when adding the refrigerant, use a liquid method. (When adding by gas, the composition of the refrigerant will change, resulting in changes in the characteristics of the air conditioner.)

6. The wall thickness of copper pipes must comply with the provisions of the "Code for Design of Copper Piping". According to the following requirements, select the allowable copper pipe wall thickness of R410A. For copper pipes and copper-aluminum pipes with a wall thickness of 0.7mm, they must not be used. !

7. When the refrigerant leaks, if you can confirm that the remaining refrigerant is not mixed with non-condensable gas, you can directly charge the liquid phase. This method can only be used 3 times for the same machine.

8. Evacuation requirements for R410A refrigerant air conditioner installation (when a new refrigerant air conditioner is newly installed, it must be evacuated, otherwise the air in the system will react with the refrigerating oil and affect the properties of the refrigerating oil). The high pressure valve is kept normally closed, and the vacuum time must be more than 10 minutes to ensure that the pressure reading is below -0.1MPa or -76cmHg.

9. The compressor oil of R22 refrigerant and R410A refrigerant is different. The engine oil used in R22 is mineral oil. The engine oil used in R410A is: synthetic oil POE or PVE. R410A refrigerant must not use mineral oil.

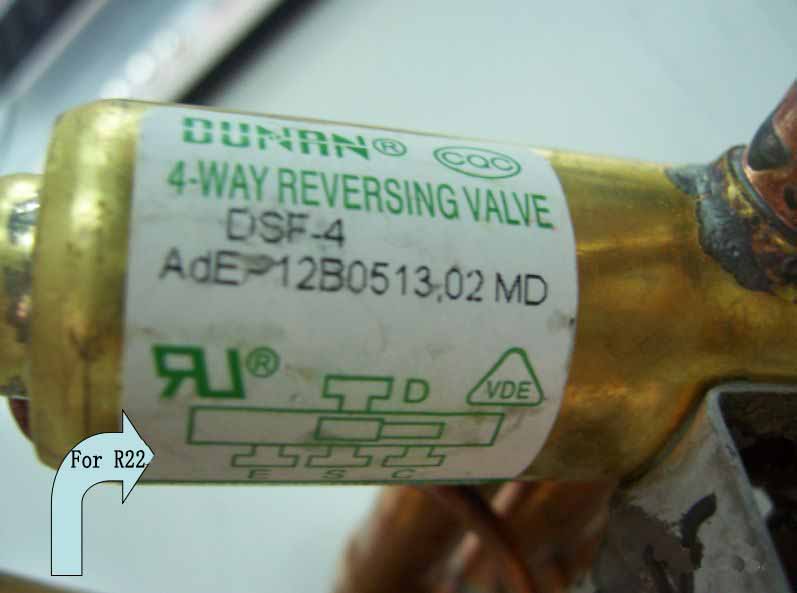

10.Compared with R22 system, R410A special accessories, compressor, R410A system must use R410A compressor, stop valve, four-way valve. The rest of the accessories can be used with R22 under pressure

R22 has a small filling port

R410A has a larger filling port

R410A four-way valve is green

R410A four-way valve is rose red