Based on SANYO DENKI R series (SANMOTION R) AC servo drives, the following describes the solutions for servo drive fault alarms.

There are many reasons for generating a certain alarm, and it is impossible to describe them all in detail. This article only describes common causes and possible solutions. For further processing, please refer to SANYO DENKI instruction manuals.

The alarm codes of SANYO DENKI Q series servo drives are basically the same as those of the R series, but the corresponding parameter numbers are different. For SANYO DENKI's PY series servo drives, the alarm codes and parameter numbers are different from those of the R series.

1. SANMOTION R Servo Drive Alarm Codes

1.1 R Series Servo Drive Alarm Code: 21 (PY Servo Drive Alarm Code: 1)

Alarm content: Overcurrent.

Possible reason: UVW short circuit.

Phenomena:

● Servo drive UVW short circuit.

● Servo motor UVW short circuit.

● The motor winding has poor withstand voltage. At this time, there is no abnormality in the winding resistance measurement at normal temperature, and the motor can rotate at low speed, but an overcurrent alarm occurs when rotating at high speed.

Solution: Please send the servo drive to SANYO DENKI Repair Center for repair.

The motor short circuit or poor withstand voltage may be seen in machining centers. Due to the atomization of cutting fluid and cutting oil, they may invade the inside of the motor (or inside the joint). Please take measures to prevent the motor from oil and water.

Note: Customers are not allowed to perform withstand voltage tests on drives or servo motors by themselves, otherwise these products may be damaged.

1.2 R Series Servo Drive Alarm Code: 43 (PY Servo Drive Alarm Code: J)

Alarm content: Abnormal regenerative resistor.

Reason: The regenerative resistor setting value is wrong.

Solution: If it is not connected to the external regenerative resistor, connect it to or use the built-in regenerative resistor.

1.3 R Series Servo Drive Alarm Code: 61 (PY Servo Drive Alarm Code: 5)

Alarm content: Overvoltage.

Possible reasons:

● The power supply voltage fluctuates greatly and instantly exceeds the maximum voltage specification.

● The load inertia is large, and the feedback voltage during stop causes the DC bus voltage to increase.

Phenomenon:

The second phenomenon mentioned above occasionally occurs in equipment with large load inertia and frequent starts and stops.

Solutions:

●If the regenerative resistor is not used originally, add an external one.

●Check the setting of the regenerative resistor and whether the parameter sy 0B has been set to 01 (when using an external regenerative resistor).

●Strengthen the management of input voltage and use UPS equipment, etc.

●Re-examine the mechanical design (whether the load inertia can be reduced), and re-plan the motion curve (whether the acceleration during deceleration can be reduced).

1.4 R Series Servo Drive Alarm Code: 85 (PY Servo Drive Alarm Code: 8)

Alarm content: Encoder initialization abnormality.

Reason: Commonly caused by the encoder not being connected.

Solution: Connect the encoder correctly.

1.5 R Series Servo Drive Alarm Code: E2

Alarm content: Abnormal internal parameters of EPPROM

Possible cause: Abnormal parameters.

Phenomenon:

E2 alarm is displayed when power is on, and the alarm cannot be cleared after writing standard parameters.

Solution:

Please send it to SANYO DENKI Repair Center for repair.

When writing parameters to the servo drive through the R-setup software, if a power interruption occurs, it may cause the abnormal parameters and E2 alarm. Please be careful not to cut off the power when writing parameters.

2. Other Common Alarm Codes for SANYO DENKI SANMOTION R Series Servo Drives

AL 21 Power failure (excessive current)

● The connection between the U, V, and W phases of the drive and the motor is short-circuited or the U, V, and W phases are grounded.

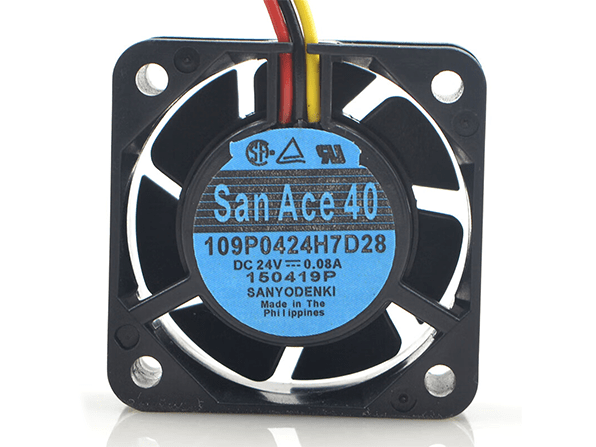

● The power module is overheated. Check the cooling fan.

AL 22 Abnormality of electric current detection value

The servo drive and motor do not match.

AL 23 Abnormality of electric current detection circuit

The internal circuit of the servo drive is faulty.

AL 24 Abnormality in communication with electric current detection circuit

AL 41 / AL 42 Overload

AL 43 Regeneration failure

The regenerative power exceeds the one allowed by built-in regenerative resistor, the load inertia is too large or the conduction time is too short, the regenerative resistor is disconnected, the impedance value of the external regenerative resistor is too large, or the drive's control circuit is faulty.

AL 51 Drive overheated

The temperature of the drive is abnormal and its internal circuit is faulty.

AL 53 DB resistor overheating, circuit failure within the drive

AL 54 Internal regeneration resistor overheating, internal circuit failure of the drive

AL 55 External regeneration resistor overheating, servo drive control board failure

AL 61 Overvoltage, servo drive control board failure

AL 62 The main circuit voltage is too low and the servo drive is defective internally.

AL 63 Main power supply phase loss

Among the 3-phase input R S T, 1 phase has no input.

AL 71 Voltage drop in control power supply

AL 72 +12V power supply dropped

AL 81 The pulse signal of phase A and B of the encoder is abnormal.

AL 82 Absolute value signal disconnected

AL 83 External encoder phase A and phase B signal failure

AL 84 Communication failure between encoder and drive

AL 85 Encoder initial process error

AL 87 CS disconnection

AL 91 Encoder command abnormality

AL 92 Encoder FORM abnormality

AL 93 Encoder SYNC abnormality

AL 94 Encoder CRC abnormality

AL B2 Encoder abnormality 2

AL B3 Absolute encoder rotation counter abnormality

AL B4 Absolute encoder single-turn counter abnormality

AL B5 When the absolute encoder is connected to the power supply, the speed exceeds the allowed.

AL B6 Encoder internal storage error

AL B7 Abnormal acceleration

AL C1 Over-velocity

AL C2 Speed control abnormality

AL C3 Speed feedback abnormality

AL D1 Excessive position deviation

AL D2 Position command pulse frequency abnormality 1

AL D3 Position command pulse frequency abnormality 2

AL DFH Test mode off

AL E1 EEPROM abnormality

AL E2 Internal RAM abnormality

AL E3 EEPROM checksum abnormality

AL E4 CPU-ASIC processing error

AL E5 Parameter error 1

AL E6 Parameter error 2

AL F1 Task process error

AL F2 Initialization timeout

PY Series Fault Codes

1 OC Power supply abnormality (overcurrent)

2 OL Overload

5 OV Overvoltage

6 OS Overspeed

7 PE Control power supply abnormality

8 DE Sensor abnormality

9 MPE Low main power

A FP Main power supply phase loss

C SE speed control abnormality

D OVF Excessive deviation

E EXOH External overheating

F DSPE Servo information processing abnormality

H RGOH Internal regeneration resistor and DB resistor overheated

J RGOL Regenerative abnormality

P MEME Memory abnormality

U AEE Absolute encoder battery alarm

No display CPUE CPU abnormality