Share┃Causes and solutions for ice block, dirty block, and oil block

Foreword: The blockage of the refrigeration system is mainly caused by the ice blockage, dirty blockage or oil blockage of the capillary tube, or the dirty blockage of the dryer filter. After the refrigeration system is blocked, because the refrigerant cannot circulate, the compressor will not stop for a long time, the box is not cooling or the cooling is slow, and the condenser is not hot. The following will introduce the specific content of the solution to the blockage of the refrigeration system.

Causes and failure phenomena of ice blocking

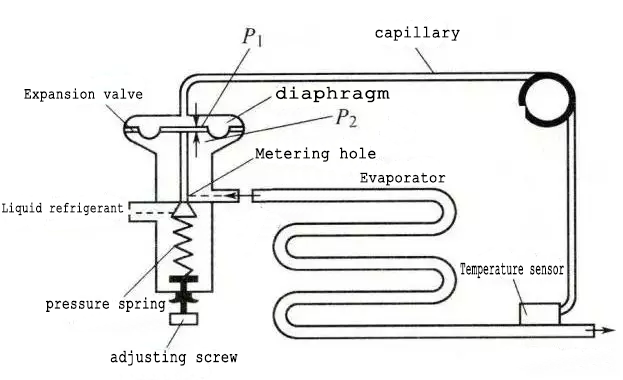

The ice block failure is mainly due to excessive moisture in the refrigeration system. With the continuous circulation of the refrigerant, the moisture in the refrigeration system gradually concentrates at the outlet of the expansion valve. Because the temperature at the outlet of the expansion valve is the lowest, the water freezes. And gradually increase, to a certain extent, the expansion valve is completely blocked, the refrigerant cannot circulate, and the cold storage does not cool.

The performance of ice blockage in the refrigeration system is the normal operation in the initial stage, the frost in the evaporator, the heat dissipation of the condenser, the stable operation of the unit, and the clear and stable sound of refrigerant activity in the evaporator. With the formation of the ice block, the audible airflow gradually weakens and intermittently. When the blockage is severe, the airflow sound disappears, the refrigerant cycle is interrupted, and the condenser gradually becomes cooler.

Due to the blockage, the exhaust pressure increases, the machine operating sound increases, there is no refrigerant in the evaporator, the frosting area gradually decreases, the temperature gradually increases, and the temperature of the expansion valve also rises, so the ice cubes begin to melt. At this time, the refrigerant begins to recirculate again. After a period of time, ice blockage occurs again, forming a periodic flow-blocking phenomenon.

Troubleshooting of ice blockage:

The ice block failure of the refrigeration system is due to excessive moisture in the system, so the entire refrigeration system must be dried. There are two ways to deal with it:

1. Use a drying box to heat and dry each component, remove the compressor, condenser, evaporator, expansion valve, and return pipe in the refrigerant system from the cold storage, and put it into the drying box for heating and drying.

2. Adopt heating vacuuming and secondary vacuuming to remove the moisture of each component of the refrigeration system.

Causes and failure phenomena of dirty blocking

The formation of dirty blockage is caused by excessive impurities in the refrigeration system. The main sources of impurities in the system are: dust and metal scraps in the cold storage manufacturing process, the oxide layer on the inner wall surface of the pipe is peeled off when the pipe is welded, the inner and outer surfaces of the parts are not cleaned during the processing, and the pipeline is not tightly sealed. The dust enters the pipe. , The refrigerating machine oil and refrigerant contain impurities, and the low-quality desiccant powder in the dry filter; in addition, it is easy to weld the expansion valve nozzle when welding the expansion valve and the dry filter.

The difference between ice blockage and dirty blockage: the refrigeration can be restored after a period of time when the ice blockage occurs, forming a blockage for a while, blockage for a while, blockage for a period of time. After the dirty block occurs, the cooling can no longer be done.

The troubleshooting method of the expansion valve's dirty blockage:

Use high-pressure nitrogen combined with other methods to blow out the dirt from the blocked expansion valve. After the expansion valve is blown through, the components in the refrigeration system are cleaned and dried and then reassembled and welded to eliminate the fault. If the expansion valve is severely clogged and the above-mentioned methods cannot eliminate the fault, use the method of replacing the expansion valve or troubleshooting.

Oil blockage and other pipeline blockage failures

The main reason for the oil blockage in the refrigeration system: the compressor cylinder is seriously worn or the clearance between the piston and the cylinder is too large.

The gasoline discharged from the compressor is discharged into the condenser, and then enters the filter drier together with the refrigerant. Due to the high viscosity of the oil, it is blocked by the desiccant in the filter. When the oil is too much, it will form a blockage at the inlet of the filter. The refrigerant cannot circulate normally, and the cold storage is not cooling.

The reasons for the blockage of other pipelines are: the pipe was blocked by the solder when the pipe was welded; or the replaced pipe itself was blocked when the pipe was replaced and was not found. The above blockage is caused by human factors, so it is required to weld and replace the pipe , The operation and inspection should be carried out according to the requirements, and it will not cause artificial jamming.

Troubleshooting of oil blockage:

The occurrence of an oil block failure indicates that there is too much refrigerating machine oil remaining in the refrigeration system, which affects the refrigeration effect and even fails to refrigerate. Therefore, the refrigerating machine oil in the system must be removed.

When the filter oil is blocked, a new filter should be replaced. At the same time, high-pressure nitrogen should be used to blow out part of the refrigerating machine oil accumulated in the condenser. When nitrogen is introduced, an electric hair dryer can be used to heat the condenser.