Judgment and repair method of refrigeration compressor jam

Step 1: Measure the compressor current

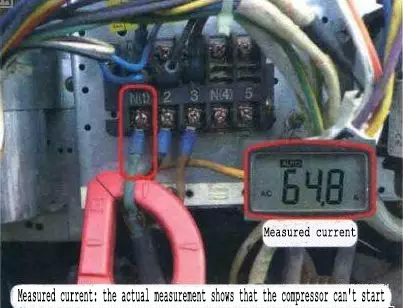

First use the AC current gear of the multimeter, clamp the N-terminal lead of the outdoor unit with the clamp head, measure the outdoor unit current, when the compressor is powered on, the measured current is about 65A, which is much larger than the starting current, indicating that the compressor may be stuck Can not start.

When the compressor is started, measure the voltage at the connection terminal to be about AC 210V, indicating that the power supply voltage is normal, and it is preliminary judged that the compressor capacitor is damaged. Replace the test machine with a new capacitor of the same capacity, the fault remains, and the current at the N terminal is still about 65A, so that the compressor capacitor fault is eliminated, and the compressor is preliminarily judged to be damaged.

Step 2: Measuring the resistance of the compressor coil

In order to judge whether the compressor is damaged by short-circuit coil or damaged cylinder, disconnect the power supply of the air conditioner, use a multimeter to measure the resistance of the compressor coil: the measured resistance of the red wire common end (C) and blue wire running winding (R) is 1.1 ohm, the resistance value of the red wire C and yellow wire start winding (S) is 2.3 ohm, the resistance value of the blue wire R and yellow wire S is 3.3 ohm, and the resistance value of the compressor coil is judged to be normal according to the results of 3 measurements.

Step 3: Check the compressor terminal

Burning out of the connecting terminal or connecting wire of the compressor will also cause failure to start or no power supply. Therefore, check the wiring terminal lead before confirming that the compressor is damaged.

Example: Check that the wiring terminals and lead wires are in good condition, loosen the two-way valve nut of the outdoor unit, vent all the fluorine R22 of the refrigeration system, and test the machine again, but the compressor still cannot start. The indoor unit still stops the compressor and the compressor after 3 seconds. The outdoor fan provides power to eliminate the system's dirty and blocked faults.

Unplug the 3 leads of the compressor coil and wrap the joints with insulating tape. Turn on the power again. The outdoor fan keeps running and no longer stops, but the air conditioner does not cool down and does not report the code. It is determined that the compressor cylinder is damaged.

4. Treatment method of compressor jam:

1. Capacitor start method: Increasing the capacitor is one of the most common methods. Simply put, add a capacitor to the original capacitor or replace it with a larger capacitor to increase the starting torque and make the compressor easier to run. Note: The compressor shuts down immediately after starting for two or three seconds! This method is often used by technicians and still has a good repair rate.

2. Percussion method: generally choose a wooden hammer or select available objects on the spot. When the press is started, a heavy hammer strikes three solder points on its body. But you must pay attention to it, you can't knock it out. Gently tap the compressor shell to loosen the jammed part slightly. Sometimes it can start operation or increase the power supply voltage by 10%, and start shocks several times. This method can solve the problem of insufficient lubrication. The compressor is particularly effective.

3. Air pressure shock method: release the freon to reduce the pressure, then remove the compressor separately, and use nitrogen from the high-pressure pipe to give the compressor a reaction force of 0.1MPA. Make the axle holding mechanism loose. Inflate for 5 minutes. Then use the above method.

4. Three-phase power starting method: If none of the above works, you can use three-phase power starting method. The connection method is N to C, R and S are connected to different phases of live wire, plug in and start within 6 seconds.

If none of the above methods work, okmarts.com prompts you, then you need to replace the new compressor, the new compressor is not allowed to stand upside down during transportation.