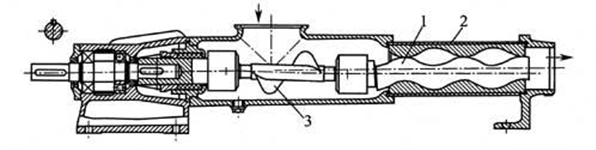

Figure 1: The appearance and design mode of 2SK water ring vacuum pump.

The vacuum pump refers to a device or equipment that uses mechanical, physical, chemical or physical-chemical methods to extract air from the pumped container to obtain a vacuum. Generally speaking, vacuum pump is a device that uses various methods to improve, generate and maintain vacuum in a closed space.

According to the working principles of the vacuum pump, it can be basically divided into two types: gas trap pump and gas transfer pump. The vacuum pump is widely applied in metallurgy, chemical industry, food, and electronic coating, and other industries.

2. Structural Characteristics

2.1 Overall Structure

Figure 2: The structure and features of single-screw pump.

The configuration of pump body of vacuum pump determines its overall structure.

The inlet and exhaust port of vertical structure are set horizontally, with convenient assembly and connection pipelines. But this pump has high center of gravity and poor stability in high-speed operation, as a result, such structure is mostly used for small pump.

The inlet and exhaust port of horizontal pump are designed in up and down position respectively. Sometimes in order to facilitate the installation and connection of the vacuum system pipeline, the exhaust port can be connected horizontally, where the inlet and exhaust directions are perpendicular to each other. At this time, the exhaust port can be opened from the left or right direction, except for one end of the exhaust pipe, the other end is blocked or connected to the bypass valve.

The structure of this pump has a low center of gravity and great stability in high-speed operation, and thus it is mostly used for medium, large pump. The two rotor shafts of the pump are installed perpendicular to horizontal plane. This structure has easily controlled assembly gap, convenient rotor assembly, small size. However, this structure of pump has high center of gravity and inconvenient disassembly and assembly of gear, and its lubrication mechanism is relatively intricate.

2.2 Transmission Mode

The two rotors of the vacuum pump are operated relatively synchronously through a pair of high-precision gears. Active shaft is connected with the motor by the coupling.

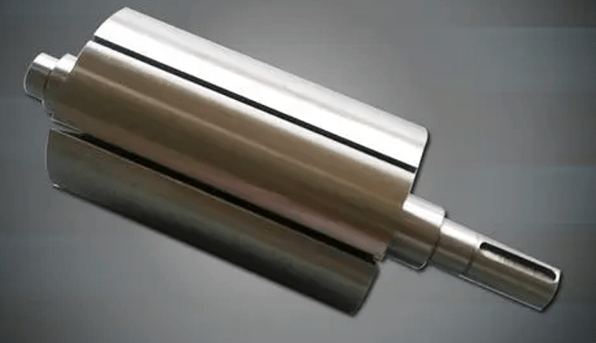

Figure 3: Different types and models of vacuum pump rotor.

There are two main types of configurations in transmission modes. One is that the motor and the gear are placed on the same side of the rotor. The passive rotor is directly driven by the motor end gear, so that the torsional deformation of the active rotor shaft is small, and the gap between the two rotors will not be changed due to the large torsional deformation of the active shaft, and therefore the gap between the rotors remains unchanged during operation.

The biggest disadvantages of this mode are as follows. Three bearings on active shaft increase the difficulty of process and assembly, and the disassembly and adjustment are inconvenient; the overall structure is asymmetrical, and the center of gravity of the pump is biased towards the motor and gearbox side.

2.3 Characteristics

1.Larger pumping speed in a wider pressure range.

2.The rotor has good geometric symmetry, so that it has small vibration stable operation. There are gaps between the rotors and between the rotors and the casing, so that it is unnecessary to use lubricant, and the friction loss is small, which can greatly reduce the driving power, and therefore a higher speed can be achieved.

3.There is no need for oil sealing and lubrication in the pump cavity, which can reduce the pollution of oil vapor to the vacuum system.

4.There is no compression in the pump chamber and no exhaust valve. It has simple and compact structure, insensitive to dust and water vapor in the pumped gas.

5.It has low compression ratio, and poor effect of hydrogen pumping.

6.It is difficult to process and inspect that the surface of the rotor is a complicated curve cylinder.

Figure 4: Smooth surface of vacuum pump surface.

Related Info

Six Common Faults and Solutions of Water PumpClassification of Water Pump

Working Principles and Characteristics of Common Water Pumps

Four Characteristics of Water Pump in Energy Conservation

The Installation and Maintenance of Water Pump