Figure 1: A circuit breaker in operation.

Molded case circuit breakers can automatically cut off the current after the current exceeds the trip setting. Plastic case refers to the use of plastic insulators as the outer casing of the device to isolate the conductors and the grounded metal parts. Molded case circuit breakers typically contain a thermal-magnetic trip unit, while larger molded case circuit breakers are equipped with solid-state trip sensors. The trip unit is divided into: thermal magnetic trip and electronic trip.

The following will explain 8 most important parameters of a molded case circuit breaker.

1. Rated Voltage

The rated voltage on the nameplate of the circuit breaker refers to the rated voltage of the main contact of the circuit breaker, which is the value that ensures the long-term normal operation of the contactor.

2. Rated Current

The rated current on the contactor nameplate refers to the rated current of the main contact of the circuit breaker, which is the value to ensure the long-term normal operation of the contactor.

3. Trip Current

The trip current is the current setting value that makes the overcurrent release operate. When the circuit is short-circuited or the load is seriously overloaded, and the load current is greater than the tripping current, the main contact of the circuit breaker is broken.

4. Overload Protection Current, Time Curve

The overload protection current and time curves are inverse time characteristic curves. The higher the overload current, the shorter the time for the thermal release to operate.

Figure 2: A circuit breaker panel.

5. Rated Voltage of the Undervoltage Release Coil

The rated voltage of the undervoltage release coil must be equal to the rated voltage of the line.

6. Rated Voltage of the Shunt Release Coil

The rated voltage of the shunt release coil must be equal to the control power supply voltage.

7. Rated Breaking Capacity

There are two types of breaking capacity indicators of circuit breakers: rated breaking capacity (Icu) and service breaking capacity (Ics).

Icu is the limit parameter of the breaking capacity of the circuit breaker. After breaking several short-circuit faults, the breaking capacity of the circuit breaker will decrease.

Ics is a breaking index of the circuit breaker, that is, after breaking several short-circuit faults, it can still ensure its normal operation.

For molded case circuit breakers, Ics is qualified as long as it is greater than 25% Icu. The Ics of the most circuit breakers on the market are between 50%-75% Icu.

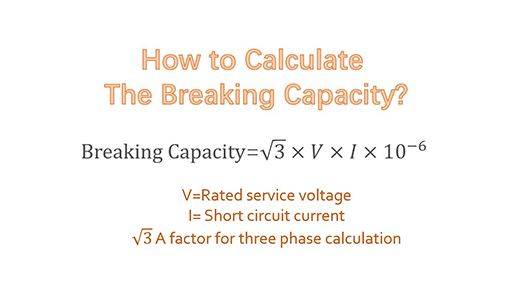

8. The Current Breaking Capacity

The current breaking capacity refers to the ability to interrupt when the circuit breaker trips when the circuit is short-circuited.

Figure 3: Formular of the breaking capacity.

When a short circuit occurs in the circuit, the contacts of the circuit breaker open rapidly to generate an arc, which is equivalent to adding a rapidly increasing arc resistance in series to the circuit. Therefore, this limits the increase of fault current, reduces the adverse effects of the electromagnetic effect, electrodynamic effect and thermal effect of the short-circuit current on the circuit breaker and electrical equipment, and prolongs the service life of the circuit breaker. The shorter the breaker opening time, the better the current breaking capacity, and the closer Ics is to Icu.

Related Info

4 Common Types of Circuit BreakersHow do Circuit Breakers Extinguish Electric Arc?

Top Circuit Breaker Brands

Classifications of Air Cylinders

What is a Miniature Circuit Breaker?