Figure 1: Classifications of Air Cylinders.

The air cylinder, also known as the pneumatic cylinder, is a cylindrical metal part that makes the piston to perform a reciprocating motion. The air in the cylinder motor transforms thermal energy into mechanical energy through expansion; and the air pressure is increased when the air is compressed by the piston in the cylinder compressor. Air cylinders have wide applications, including printing (tension control), semiconductors (spot welding, chip grinding), automation control, robotics, and more.

According to the reciprocating motions, air cylinders are divided into linear types and swing types. These are further divided into subtypes, which will be introduced in details.

1. Reciprocating Linear Air Cylinders

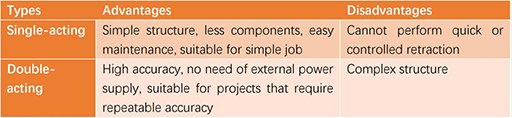

Linear cylinders are suitable for providing linear in or out linear motion for a variety of applications. Linear cylinder equipment using a standard motor typically uses the motor as a separate cylinder attached to the side of the actuator, either parallel to the cylinder or extending out of the side, positioned perpendicular to the actuator. Some common reciprocating linear air cylinders are single-acting, double-acting, diaphragm, and impact air cylinders.

1.1 Single-acting Air Cylinders

Single-acting air cylinders work by transmitting hydraulic fluid or output force in only one direction. Inside the cylinder, the piston rod can be pushed outwards but not pulled back, so a force in the opposite direction is required to return the piston rod to its original position. Traditionally, single-acting air cylinders can be supplemented by auxiliary components such as pumps, motors or internal springs. Since single-acting air cylinders can only work in one direction, there are two forms of single-acting air cylinders on the market: pull or push.

1.2 Double-acting Air Cylinders

In contrast, double-acting air cylinders offer greater complexity. Unlike single-acting air cylinders, they are capable of transmitting hydraulic fluid or output force in both the extension and retraction directions. Ports are located on both ends of the cylinder, allowing the piston rod to move forward and backward. This movement is caused by port replacement, with one end receiving pressure, generating thrust and performing a push-pull motion.

Figure 2: Comparison between single-acting and double-acting air cylinders.

1.3 Diaphragm Air Cylinders

The diaphragm air cylinder is a cylinder that uses compressed air to push the piston rod through the diaphragm for reciprocating linear motion. It only takes in (exhaust) gas at one end, with simple structure and low gas consumption. It consists of parts such as cylinder block, diaphragm and piston rod. Its function is similar to that of a piston cylinder.

1.4 Impact Air Cylinders

The impact air cylinder is a special function cylinder specially developed to meet the requirements of high impact force. It is small in size, simple in structure, easy to manufacture, low in air power consumption but can generate considerable impact. It can be used for marking steel workpieces, parts punching, blanking and other operations that require high impact force to complete.

2. Reciprocating Swing Air Cylinders

The reciprocating swing air cylinder is a pneumatic actuator that uses compressed air to drive the output shaft to perform reciprocating and rotatory motion within a certain angle range. It is used for opening and closing of valves and arm movements of robots. The rotary air cylinder and the gas-liquid damping air cylinder are examples of common types of reciprocating swing air cylinders.

2.1 Rotary Air Cylinders

The intake and exhaust ducts and the air guide of the rotary air cylinder are fixed, and the body can rotate relatively and act on the machine tool fixture and the wire coiling device. Rotary air cylinders are mainly used in printing (tension control), semiconductors (spot welding machines, chip grinding).

2.2 Gas-liquid Damping Air Cylinders

The gas-liquid damping air cylinder is also called the gas-liquid steady speed cylinder, which is suitable for the occasions where the cylinder is required to move at a slow and uniform speed. Hydraulic oil is added to the internal structure of the cylinder to achieve uniform movement of the cylinder.

Figure 3: Classification of reciprocating air cylinders.

Related Info

Choose the Right Electric Valve ActuatorDifferences between a Sensor and an Actuator

Dealing with Actuator Failures: Common Causes and Solutions

What is a Pneumatic Actuator?

Functions of the Electric Actuator