Figure 1: Pressure transmitters are used in the industrial scene.

Pressure transmitters and pressure gauges are both widely used in pressure measurement and control in industrial processes. Do you know the difference between them? Firstly you may need to figure out the definition of the two types of devices. Knowing their characteristics and notes of using, you would get their differences.

What is the Pressure Transmitter?

A transmitter is composed of the pressure sensing element (or the pressure sensor), a measuring circuit, and a process connection. It converts the sensed gas and liquid parameters to standard electrical signals, such as 4~ 20mA DC. And the signal can be measured, indicated, and regulated by secondary instruments such as an indicating alarm, recorder, and regulator.

Figure 2: Rosemount transmitter 3051CD3A22A1AB4M5DF

What is the Pressure Gauge?

Pressure gauges use elastic elements to sense, measure, and indicate the pressure when it is higher than the ambient pressure. We could find pressure gauges in almost all industrial processes, including the heating pipe network, oil and gas transmission, water and gas supply system, vehicle maintenance plants. Also, they are used in scientific researches.

Especially in industrial process control and technical measurement, pressure gauges are increasingly used thanks to the high mechanical strength and mass production of elastic elements. Having known the definitions of pressure transmitters and pressure gauges, you would know about the differences between the two kinds of devices by the following.

Figure 3: A pressure gauge.

Differences between the Pressure Transmitter and Pressure Gauge

* Definition

A Pressure gauge is an instrument in which the elastic element is a sensing element, and the use of expansion tube pressure sensing is a driving force for pressure measurement. But a transmitter uses the pressure sensor, and through the conversion, the induced pressure will be the standard output.

* Features

The pressure transmitter has the advantages of wide applications, high stability, light mass, small volume, good wear resistance, high measuring accuracy, easy maintenance.

But note that there should be a corresponding display instrument that supports the use and power supply.

The pressure gauge with a simple internal structure is easy to install or use, and it is suitable for installation in various pipelines.

But its shortcoming is the lower measuring accuracy.

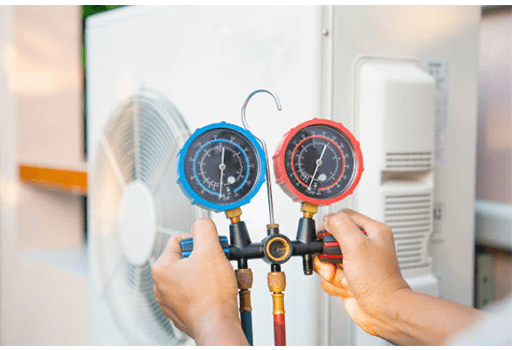

Figure 4: Someone is using pressure gauges for the detection.

* Use Notes

Pressure transmitters require higher accuracy of standard instruments for the calibration.

Pressure gauges only verify an input/output, but pressure transmitters would need to verify the relationship between the input and the communication data.

Calibrating pressure gauges requires the corresponding measurement qualification, while for pressure transmitters, only manufacturers and new construction are required to be qualified.

The precision of a pressure gauge with no output is not high, and workers can not use it by hand. Generally, we should calibrate 5 points on them, and the difference between pressurizing and depressurizing is not identical. However, calibration of smart pressure transmitters requires zero point and full scale only.

The output of the pressure gauge is indicated as scales on its own. On the contrary, the pressure transmitter is the current output that must be connected with the ammeter of the corresponding precision level.

Figure 5: Pressure gauges are displaying different scales.

From the above description, it is obvious that the pressure transmitter can provide more accurate measurement under the same working conditions, indicating the function expansion is much higher than that of the pressure gauge in the future.

Related Info

How to Calibrate a Pressure Transmitter Before UseTroubleshooting of Diffusion Silicon Pressure Transmitter

Differences Between Smart Pressure Transmitter and Analog Pressure Transmitter

Use of Differential Pressure Transmitter and Common Troubleshooting