Bearing Working Principle

Bearings play an irreplaceable role in mechanical design. They involve very wide applications. We would say that the shaft without a bearing is just an iron bar. For refrigeration compressors, bearings are also essential. This article will take you to look at the working principle and troubleshooting of bearings.

Figure 1: A compressor bearing consists of an inner ring, an outer ring, a rolling body, and a cage.

Bearings based on the development of rolling bearings are to replace sliding friction with rolling friction. The bearing generally consists of two rings, a rolling body, and a cage. Bearings are a type of mechanical base parts with universality, high standardization, and serialization.

To meet the requirements of different working conditions of various machines, rolling bearings are characterized with different load capacity, structure, and service performance. However, the most basic structure includes an inner ring, an outer ring, a rolling body, and a cage -- the Four main parts.

Sealed bearings are added with lubricant and sealing ring (or dust cover), and they are also known as the Six main parts. And naming various bearing types is mostly according to the names of rolling bodies.

* Roles of parts in bearings

For centripetal bearings, the inner ring usually matches with the shaft journal and runs together with the shaft. But the outer ring matches with the bearing housing or mechanical shell hole into a transition, playing a supporting role. However, in some cases, the outer ring runs, and the inner ring would play a supporting role, or the inner and the outer ring are both running.

For thrust bearings, the part that runs with the shaft journal is called the shaft washer. What transitively matches with the bearing housing or the mechanical shell hole and plays a supporting role is the housing washer.

Figure 2: A thrust bearing.

The rolling body (steel ball, roller, or needle) of the bearing is evenly arranged between the two rings with the help of the cage for rolling, and the body’s shape, size, and quantity directly affect the bearing's load capacity and performance.

In addition, the cage can also guide the rolling body to spin and improve the internal lubrication performance of the bearing. Despite various types of bearings for wide uses, their working principle is the same, which has been introduced above.

Air Conditioner Bearing Troubleshooting

The bearing is an important part of modern machinery equipment to support the rotating body, reduce the friction coefficient in the process, and ensure the precision of rotation.

Therefore, bearings are applied far and wide for the strong market demand. At present, Asian countries have occupied half of the global bearing consumption, becoming the largest bearing consumption market in the world.

High-quality compressor bearings can be used for a long time under the correct operation. Definitely, improper operation will also cause a series of failures. In a central air conditioning system, the most common faults are burnt and peeling compressor bearing.

Compressor Bearing Burning up

* Fault phenomenon

The bearing is overheating to discolored and then burns up to stop rotating.

Figure 3: A burnt bearing.

* Causes

Extremely small clearance, including the deformation part.

Insufficient lubrication or improper lubricant.

Excessive load (preload).

Roller deflection.

* Solution

Adjust clearance - increase clearance.

Check the lubricant type to ensure the injection amount.

Inspect the use conditions.

Prevent positioning error.

Examine the circumstances around the bearing (including bearing heating).

Improve the assembly method of the bearing.

Compressor Bearing Flaking

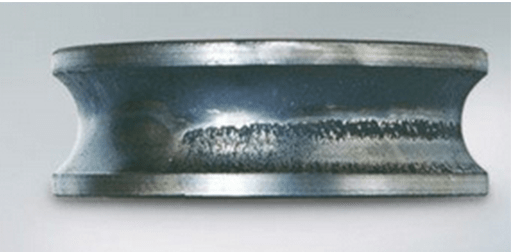

Figure 4: A bearing has been flaking.

* Fault phenomenon

The running surface is obviously convex and concave after peeling off.

|

Reasons |

Solutions |

|

Excessive load and improper use |

Note the use conditions. |

|

Wrong installation |

Check the mounting method. |

|

Low precision of shaft or bearing box |

Inspect the machining precision of the shaft and bearing box. |

|

Extremely small clearance |

Adjust the clearance. |

|

Some other object invasions |

Study the design around the bearing. |

|

Rust |

Check the lubricant and lubrication method. |

|

Hardness decrease caused by abnormal high temperature |

Replace the bearing. |

Table 1: Air conditioner compressor bearing flaking - reasons and solutions.

As is known to us, compressors are an indispensable part of factory equipment, petrochemical equipment, air conditioning system, and industrial refrigeration. These industries require compressor bearings of low heat, long life, resistance to working conditions, low noise, low vibration, and other properties.

Hope that the article could help you deal with the problems of bearings to improve the working efficiency and service life of the compressor.

Related Info

Air Compressor Troubleshooting and SolutionsList of Problems and Solutions for Centrifugal Air Compressor

Car AC Compressor Troubleshooting-- Best Suggestions