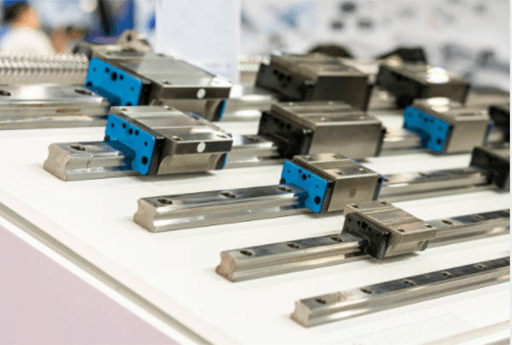

Figure 1: Linear guideways.

From the perspective of appearance, the linear guideway is a long strip-shaped metal shell, which is true in itself. The basic material of the linear guideway is profile. There are far more than one profile material used to make the linear guideway. What are the profiles used to make it? The common materials of general guideway include cast iron, steel, non-ferrous metals and plastics. The following are several common types of linear guideway profiles.

Common Types of Linear Guideway Profiles

1.1 Chromium Bearing Steel GCr15

Figure 2: Chromium bearing steel

Bearing steel, also known as High-carbon chromium steel, has a carbon content Wc of about 1% and a chromium content Wcr of 0.5% - 1.65%. High- carbon chromium bearing steel GCr15 is the largest bearing steel in the world, with carbon Wc of about 1% and chromium Wcr of about 1.5%.

Bearing steel is the steel used to make balls, rollers and bearing rings. Bearing steel has high and uniform hardness, wear resistance and high elastic limit. The requirements for the uniformity of chemical composition, the content and distribution of non-metallic inclusions and the distribution of carbides of bearing steel are very strict. It is one of the most stringent steel types in all steel production.

Bearing steel can be divided into Fully quenched bearing steel (mainly high-carbon chromium steel, such as GCr15), Carburized bearing steel, Stainless bearing steel and High-temperature bearing steel according to chemical composition, performance, processing technology and purpose.

1.2 Carburized Bearing Steel Profile G20crmo

Figure 3: Carburized bearing steel profile

Carburized bearing steel is the support of various mechanical parts. Its working environment may be ultra-high temperature, ultra-low temperature, strong (slight) vacuum, strong impact, high wear and ultra-high speed.

The structural characteristics and working conditions of Carburized bearing steel require that bearing parts must have high hardness, wear resistance, contact fatigue strength, good toughness, dimensional stability, corrosion resistance and cold and hot working properties.

1.3 Industrial Aluminum Profile

Some places with low load capacity usually use Industrial aluminum profiles. As we all know, Industrial aluminum profile is an alloy material with aluminum as the main component. The material of aluminum alloy is light, the hardness can meet the requirements of the guideway, and the weight of equipment can be reduced to a certain extent. The surface of Industrial aluminum profile is bright and silvery white with strong gloss and good corrosion resistance. It is suitable for the use of medical devices and high-end equipment. Some linear modules will also use high-strength aluminum alloy materials as bases and aluminum alloy sliding seats.

1.4 Stainless Steel Profile

Figure 4: Stainless steel profile

The stainless steel has good corrosion resistance, and Chromium containing stainless steel also integrates mechanical strength and high extensibility.So, it is easy to process and manufacture. Some Japanese linear guideway brands use stainless steel profiles,like HIWIN.

1.5 Carbon Steel Profile

Carbon steel profile is also a kind of linear guideway profile material that many well-known brands will choose. Carbon steel is an iron carbon alloy with a carbon content of 0.0218% ~ 2.11%, also known as Carbon steel. Generally, it also contains a small amount of Silicon, Manganese, Sulfur and Phosphorus. Generally, the higher the carbon content in Carbon steel, the greater the hardness and strength, but the lower the plasticity.

1.6 Cast Iron

Figure 5: Cast iron

Cast iron is an iron carbon alloy with a carbon content of more than 2.11%. The carbon content of industrial cast iron is generally 2.5% ~ 3.5%. In addition to carbon, cast iron also contains 1% ~ 3% Silicon, Sanganese, Phosphorus, Sulfur and other elements. Corrosion resistant cast iron also contains Nickel, Chromium, Molybdenum, Aluminum, Copper, Boron, Vanadium and other elements. Carbon and Silicon are the main elements affecting the microstructure and properties of cast iron. According to the form of carbon, cast iron can be divided into gray cast iron, white cast iron and mottled cast iron

Cast iron is widely used in sliding guide rail because of its good wear resistance and shock absorption, high thermal stability, easy casting and cutting, and low cost. HT20 - 40 (Grade 1 cast iron) is commonly used for gray cast iron, and HB180 ~ 200 is more suitable for hardness.

Properly increasing the carbon content and phosphorus content in cast iron and reducing the silicon content can improve the wear resistance of guideway. We can use wear resisting casting iron if gray cast iron cannot meet the wear resistance requirements.

Related Info

How to select linear guidewaysHow to select the thermal expansion valve

6 Things about your wine cooler notworking