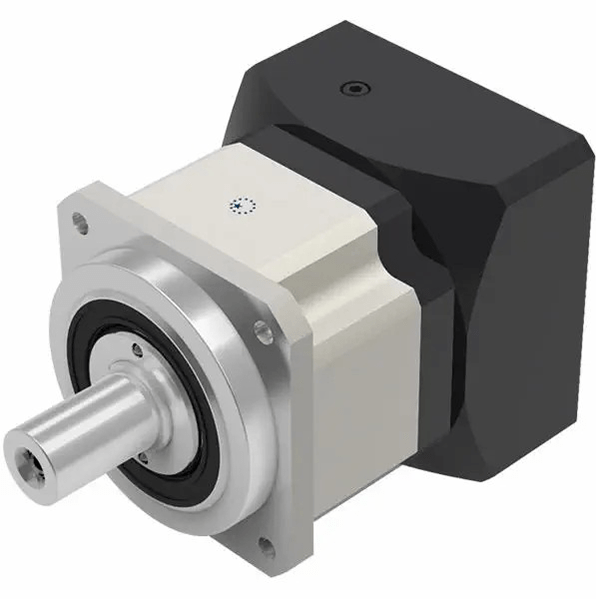

Figure 1: Vortex Inline Helical Speed Reducers.

Gear reducers are generally used for transmission equipment with low speed and high torque. The ratio of the numbers of teeth of the big and small gears equals the transmission ratio. Due to development, more and more gear reducers are used in various industries, and the gear reducers used in different industries are also various. 6 types of commonly used gear reducers will be introduced as follows.

Planetary Gear Reducers

The planetary gear reducer is also called the planetary reducer and the servo reducer. In the reducer family, the planetary reducer has many advantages such as small size, high transmission efficiency, wide deceleration range and high accuracy. It is, therefore, widely used in servo motor, stepper motor, direct current (DC) motor and other transmission systems.

Its function is to reduce the speed, increase the torque and reduce the inertia ratio of the load/motor under the condition of precision transmission. Planetary gear reducers are widely used in construction, petroleum, marine, shipbuilding, steel, non-ferrous metals, manufacturing, automobile transmission, smart home, electronic products, robot transmission, etc.

Figure 2: Planetary gear reducer AB series.

Cylindrical Gear Reducers

The cylindrical gear reducer is a power transmission mechanism. It uses the speed converter of the gear to decelerate the number of revolutions of the motor to the required number, and obtains a large torque.

The cylindrical gear reducer is a relatively precise machine with the advantages of high bearing capacity, low noise, long life, small size, high efficiency and light weight. It is widely used in metallurgy, mining, lifting, transportation, cement, construction, chemical, textile, printing and dyeing, pharmaceutical and other fields.

Harmonic Gear Reducers

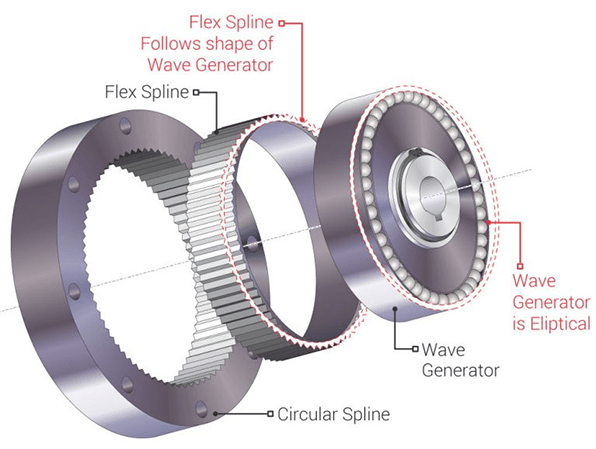

The harmonic gear reducer, also known as the strain wave gear reducer, is a reduction device. It consists of three basic components: a circular spline, a flexspline, and a wave generator that makes the flexspline radially deform.

It is a new type of transmission structure in gear reducer. It uses flexible gears to generate controllable elastic deformation waves, causing the teeth of the rigid and flexible gears to be mutually misaligned to transmit power and motion.

This kind of transmission is fundamentally different from general gear transmission — it has particularities in meshing theory, set calculation and structural design. The harmonic gear reducer has the advantages of high precision and high bearing capacity. Compared with ordinary reducers, its volume and weight are reduced by at least 1/3 due to the use of 50% less material.

Figure 3: Working principles of harmonic gear reducers.

Harmonic gear reducers are increasingly widely used in aviation, aerospace, energy, navigation, shipbuilding, bionic machinery, commonly used ordnance, machine tools, instruments, electronic equipment, mining and metallurgy, transportation, lifting machinery, petrochemical machinery, textile machinery, agricultural machinery, etc

Parallel Shaft Gear Reducers

The parallel shaft gear reducer adopts the modular design principle of unit structure, which greatly reduces the types and inventory of parts, and also significantly shortens the delivery cycle time. It has high-rigidness cast iron box body with ribs, and the gears, made of high-quality alloy steel, have gone through finishing operation, with carburizing-and-quenching hardened surface. It has the characteristics of stable transmission, low noise, large bearing capacity, low temperature rise and long service life.

The parallel shaft helical gear reducer consists of two- or three-stage helical gears, which are installed in the same box body. It is widely utilized in light industry, food, beer and beverage, chemical industry, escalators, automated storage equipment, construction, machinery, iron and steel metallurgy, papermaking, wood-based panel machinery, automobile manufacturing, water conservancy, printing and packaging, pharmaceuticals, textiles, building materials, logistics, feed machinery, environmental protection and other fields.

Micro Gear Reducers

The micro gear reducer, also known as micro gear motor, integrates the micro motor and gearbox. It is used to reduce the speed and increase the torque to meet the needs of mechanical equipment work.

Micro gear reducer products are the lifeblood of automation, which can simplify product design and save space. It is characterized by small size, large torque, low noise, full speed ratio, stable performance, instant conversion, high efficiency, energy saving and low calorific value. Micro gear reducers are widely used in smart home, consumer electronics, automotive drives, robotics, aircraft, 5th generation mobile networks (5G) communication equipment, logistics equipment, smart city equipment and other fields.

Worm Gear Reducers

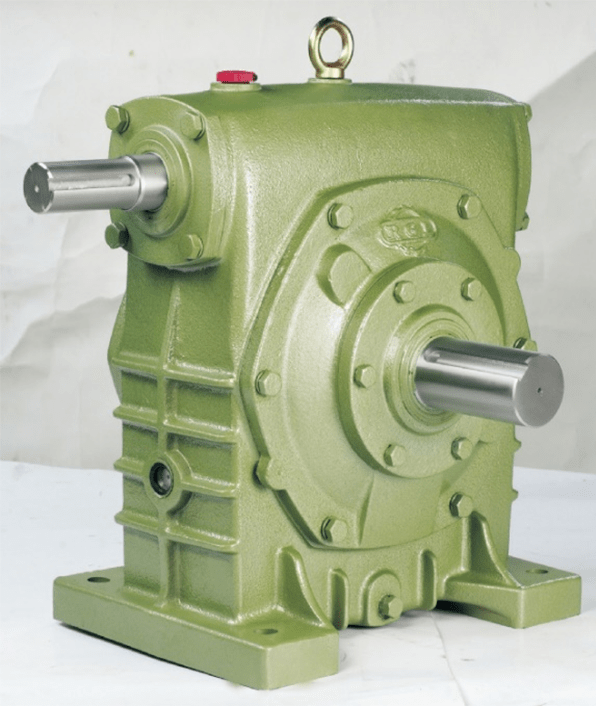

The worm gear reducer is a power transmission mechanism that uses the speed converter of the gear to reduce the number of revolutions of the motor to the required number, and obtain a large torque.

Among the mechanisms used to transmit power and motion, the application range of worm gear reducer is quite wide, including wharf, mining, transportation, lifting, construction, petroleum, marine, ship, steel, non-ferrous metal, etc.

Figure 4: W Type Worm Gear Reducer W50#-250#.

Related Info

How to Reduce Gear Noise?What is a Smart Pressure Transmitter?

Characteristics of Smart Pressure Transmitters

What is a Gear Reducer?

What is Gear Ratio?