Figure 1: AC motor.

An AC motor is a device that converts AC electrical energy into mechanical energy. The AC motor is mainly composed of an electromagnet winding used to generate a magnetic field, namely the stator winding, and a rotating armature, namely the rotor. This electric motor is made by using the phenomenon that the energized coil is forced to rotate in the magnetic field.

For example, the stator winding of a three-phase AC motor is basically three coils separated by 120 degrees from each other and connected in a delta or star shape. When a three-phase current is passed, a magnetic field is generated in each coil. By energizing three coils in a certain order, a rotating magnetic field can be obtained.

1. Types of AC Motors

1.1 According to Functions

AC motors are usually divided into: alternators (AC generators), AC motors and synchronous condensers according to their functions. Due to the reversibility of the working state of the motor, the same motor can be used as both a generator and a motor. However, this classification is not very precise, because some motors are mainly used as generators, and some motors are mainly used as motors.

Figure 2: Rotor windings.

1.2 Number of Phases

According to the number of phases, there are single-phase and three-phase AC motors. AC motors generally use a three-phase system, because three-phase AC motors have obvious advantages in terms of performance indicators, raw material utilization and price compared with single-phase motors. Three-phase motors with the same power are smaller in size, lighter in weight and lower in price than single-phase motors.

Three-phase motors have self-starting capability. The single-phase motor has no starting torque, and some special measures need to be taken to solve the starting problem.

The torque of the single-phase motor is pulsating and the noise is relatively large, but the required power supply is relatively simple. Especially in the home, it is very convenient. Therefore, single-phase motors are mostly used in small household appliances and instruments.

1.3 Relationship between rotor speed and rotating magnetic field speed

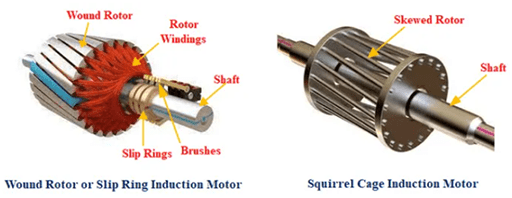

AC motors are classified into two categories: synchronous motors and asynchronous motors. Both motors use alternating current to generate a rotating magnetic field on the stator windings, but the rotor windings of AC synchronous motors usually require an exciter to supply direct current (excitation current), while induction motor rotor windings do not require current. Induction motor rotor windings are divided into two categories: squirrel cage motor and wound rotor motor.

Figure 3: Wound rotor motor and squirrel cage motor.

The rotor speed n of the synchronous motor is the same as the rotating magnetic field speed ns, which is called the synchronous speed. There is a strict relationship among ns, the frequency (f) of the connected alternating current and the number of pole pairs (P) of the motor: n=ns=60f/P. Regardless of the size of the load, the rotor speed of a synchronous motor is always the same as that of the rotating magnetic field, which is only determined by the frequency of the power supply.

The speed of the asynchronous motor is not constant, it depends on the size of the load and the power supply voltage. When the asynchronous motor works in the motor state, the rotor speed is less than the synchronous speed. In order to describe the difference between the rotor speed n and the synchronous speed ns, slip is introduced.

n=ns(1-s)=(60f1/p)*(1-s)

Where, ns--synchronous speed, n--rotor speed, s--slip, f1--power supply frequency, p--number of pole pairs

1.4 Rotational Speed

According to the operating speed, motors can be divided into high-speed motors, low-speed motors, constant-speed motors, and speed-regulated motors.

2. AC Motor Speed Control

There are several AC motor speed control methods.

1. The method of changing the number of pole pairs for speed control: change the stator winding to change the number of pole pairs of the cage motor to achieve speed control.

2. Frequency conversion speed control method: use the frequency converter to change the frequency of the motor stator power supply, thereby changing the synchronous speed.

Figure 4: ABB frequency converter.

3.Cascade speed control method: Cascade speed control means that an adjustable additional potential is connected in series in the rotor circuit of a wound motor to change the slip of the motor and achieve the purpose of speed control.

Most of the slip power is absorbed by the additional potential connected in series, and then the device of producing the additional potential is used to return the absorbed slip power to the grid or convert energy for use. According to the absorption and utilization method of slip power, cascade speed control can be divided into motor cascade speed control, mechanical cascade speed control and thyristor cascade speed control, and among them the last one is mostly used.

4. The speed control method of the rotor series resistance of the wound motor: the rotor of the wound asynchronous motor is connected in series with additional resistance, so that the slip rate of the motor is increased, and the motor runs at a lower speed.

The larger the resistance in series is, the lower the speed of the motor will be. This method is simple in equipment and convenient in control, but the slip power is consumed in the resistance in the form of heating. It belongs to step-by-step speed control, and the mechanical properties are relatively soft.

5. Stator voltage control method: change the stator voltage of the motor to obtain different speeds. Since the torque of the motor is proportional to the square of the voltage, the maximum torque drops a lot, and its speed control range is small, making it difficult to apply a general cage motor. In order to expand the range of speed control, a squirrel motor with a large rotor resistance value should be used for voltage control and speed control, such as a torque motor, or a frequency sensitive resistor can be connected in series with a wound motor.

3. Features and applications of AC motors

3.1 Features

1. The AC motor is relatively cheap to manufacture.

2. With the development of vector frequency conversion technology, it has been possible to simulate direct current with a frequency conversion motor.

3. Compared with DC motors, it has sufficient advantages in simple structure, easy maintenance, low environmental requirements, energy saving and productivity improvement, so that AC speed control has been widely used in industrial and agricultural production, transportation, national defense and daily life.

4. Compared with DC motors, AC motors are easy to be made into motors with high speed, high voltage, high current and large capacity. AC motor power covers a wide range, from a few watts to hundreds of thousands of kilowatts, or even millions of kilowatts.

3.2 Application

The working efficiency of the AC motor is high, and there is no smoke, dust, smell, no pollution to the environment, and less noise. Because of its series of advantages, it is widely used in industrial and agricultural production, transportation, national defense, commercial and household appliances, medical electrical equipment and other aspects.

4. AC vs DC Motor

DC motors and AC motors have the following differences.

Figure 5: Brushed DC motor structure.

1. First of all, the external power supply of the two is different. The DC motor uses DC as the power supply while the AC motor uses AC as the power supply.

2. In terms of structure, the principle of DC motor is relatively simple, but the structure is complex and inconvenient to maintain; while the principle of AC motor is complex but the structure is relatively simple, and it is easier to maintain than DC motor.

3. In terms of speed control, the DC motor can achieve smooth and economical speed control without the cooperation of other equipment. It only needs to change the input or excitation voltage and current to achieve speed control; while the AC motor cannot complete the speed control by itself, and it needs to use frequency conversion equipment to achieve speed changes.

4.The way the rotating magnetic field is generated is different. The DC motor is powered by direct current and does not directly generate a rotating magnetic field. It relies on the commutator that rotates with the rotor to change the direction of the current entering the rotor at any time, to make the polarity of the magnetic field between the rotor and the stator always opposite, so the rotor can rotate. The AC motor uses alternating current, as long as the stator coils are arranged in certain phases, a rotating magnetic field will naturally be generated.

Related Info

Permanent Magnet DC Motor: Types, Application, Selection Principle (2)Top 10 Brands of Linear Motors

What is DC Motor and How Does It Work?

Types of DC Motors

Permanent Magnet DC Motor: Types, Application, Selection Principle (1)