Figure 1: Flat linear motor.

A linear motor, as the name suggests, is a motor that produces linear motion. The working principle of linear motor is the same as the rotary motor and both rely on electromagnetic force to act. Structurally, a linear motor can be regarded as a rotary motor that is cut radially and stretched into a straight plate. In a linear motor, the stator is called the primary, and the “rotor" is called the secondary.

Figure 2: Rotary motor and linear motor.

1. Classification by Working Principle

Due to the above correspondence between linear motors and rotary motors, there is a corresponding linear motor for each type of rotary motor. According to the classification of working principle, linear motors can be divided into: linear DC motors, AC linear induction motors, AC linear synchronous motors and linear stepping motors, etc., as shown in the following figure.

Figure 3: Types of linear motor.

2. By Structure

Linear motors can be divided into: unilateral flat type, bilateral flat type, disc type, arc type, cylindrical type (or tubular linear motor) and so on. The most commonly used types of linear motors are flat linear motors, U-slot linear motors, and cylindrical linear motors.

2.1 Flat Linear Motor

The secondary of flat linear motor generally has the following types.

(1) Grid secondary: Generally, slots are made on a steel plate, copper strips (or cast aluminum) are embedded in the slots, and then use other copper strips to connect both ends of these copper strips embedded in the slots.

(2) Steel or magnetic secondary: Steel plays both magnetic and conductive functions. Due to the high resistivity of steel, the electromagnetic performance of the steel secondary linear motor is poor, and the normal force is also large (about 10 times the thrust).

(3) Composite secondary: a layer of copper plate (or aluminum plate) is composited on the steel plate.

(4) Copper (aluminum) or non-magnetic secondary: used in bilateral linear motors.

In the figure below, the upper is a flat linear motor, and the lower is a double-sided flat linear motor.

Figure 4: single-sided flat linear motor and double-sided flat linear motor.

Flat linear motors generally have the following types (both are brushless): slotless ironless, slotless iron core and slot iron core types.

Slotless ironless flat motors include a series of coils mounted on an aluminum plate. Since the mover (forcer) has no iron core, the motor has no suction(same as the U-slot motor). This design can help extend bearing life in some applications. The mover can be mounted from above or from the side to suit most applications.

This motor is ideal for applications that require a smooth control speed, such as scanning applications, but the flat magnetic track design produces the lowest thrust output. Typically, flat magnetic tracks have high flux leakage. Caution is therefore required to prevent the operator from being injured by the magnetic attraction between them and other materials to be attracted.

The slotless iron core flat motor is similar in structure to the slotless ironless motor, except that the iron core is mounted on a steel lamination structure, and then mounted on an aluminum backplane. The iron lamination structure is used to direct the magnetic field and increase thrust. The suction force generated between the magnetic track and the mover is proportional to the thrust generated by the motor.

The lamination structure causes the joint force to be generated. Care must be taken when installing the movers on the magnetic rails so that the suction between them does not cause injury. Slotless ironcore motors have greater thrust than slotless ironless motors.

Slotted iron core linear motor: Iron core coils are placed into a steel structure to create iron core coil units. The iron core effectively enhances the thrust output of the motor through the magnetic field generated by the gathered coils. The strong attraction between the core armature and the magnet rail can be used as a preload for the air bearing system in advance. These forces increase bearing wear, and the phase difference of the magnets reduces joint forces.

Figure 5: HIWIN iron core linear motor.

2.2 U-slot Linear Motor

U-slot linear motors have two parallel magnetic tracks between the metal plates, both facing the coil mover. The mover is supported by the rail system between the two magnetic rails. The mover is non-steel, meaning that there is no suction and no interfering force between the magnet rail and the thrust coil. The non-steel coil assembly has low inertia, allowing very high accelerations. The coils are generally three-phase, with brushless commutation. The motor can be cooled by air cooling method to obtain performance enhancement, or water cooling is used.

This design can better reduce flux leakage because the magnets are installed face-to-face in the U-shaped channel. This design also minimizes damage from strong magnetic attraction. The magnetic track of this design allows for combinations to increase the stroke length, limited only by the operational length of the cable management system, the length of the encoder, and the ability of the machine to construct a large, flat structure.

Figure 6: U-slot linear motor.

2.3 Cylindrical Linear Motor

The cylindrical linear motor adopts the support mechanism at both ends, which can simply replace the screw mechanism. The secondary is generally a thick-walled steel pipe. In order to improve the starting thrust generated by the unit volume, a layer of 1~2mm copper or aluminum pipe can be covered on the outer circle of the steel pipe to become a composite secondary, or copper rings or cast aluminum rings can be embedded on the steel pipe, becoming a cage-like secondary. The shape is like a rotary motor, and if necessary, it can be made into a rotary linear motor with both rotary motion and linear motion.

Figure 7: cylindrical linear motor.

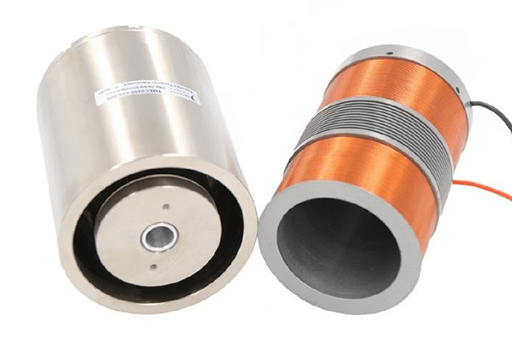

Among cylindrical linear motors, voice coil motors are more famous, divided into cylindrical voice coil motors and swing voice coil motors. Named for its structure similar to the voice coil of a speaker, it has the characteristics of high frequency response and high precision.

A potential problem with the design of tubular linear motors arises when the stroke increases, as the motor is completely cylindrical and moves up and down along the magnetic rod, with the support points only at the ends. The length of the thrust coil is limited to ensure that the radial deviation of the bar does not result in magnet contact.

Figure 8: Voice coil motor.

2.4 Disc Linear Motor

The secondary of the disc type linear motor is made into a flat disc shape, which can rotate freely around the axis passing through the center of the circle. Place the two primaries on the plane near the outer edge of the disc, so that the disc is subjected to tangential force for rotational motion. Because its operating principle and design method are the same as those of the flat-plate linear induction motor, it is still a linear motor.

Compared with ordinary rotary motors, disc linear motors have the following advantages:

(1) The lower speed can be obtained without the use of the gear reduction box, so the vibration and noise of the motor are very small.

(2) The torque and rotation speed of the motor can be adjusted by moving the radial position of the stator on the disc.

Figure 9: Disc type linear motor.

2.5 Arc Linear Motor

Some equipment does not need continuous rotation, but only swings back and forth within a certain angle. At this time, circular arc linear motors can be used. The secondary of the arc-type linear motor is cylindrical, which can rotate freely around the axis. The stator is arc-shaped and has a small air gap with the secondary cylinder, like a small section of the stator of a rotary motor.

Figure 10: Arc linear motor.

Related Info

What is Permanent Magnet Synchronous Electric MotorWhat is Synchronous Motor

What are the Advantages of Synchronous Reluctance Motor?

What is the Difference between Synchronous and Induction Motor

What is Linear Motor and How Does It Work?