As the product of the development of modern science and technology, servo system with its irreplaceable role and excellent performance, can be found in almost every area of industry. Servo system is an important part of textile machinery automation and digital control system.

Figure 1: A worker makes yarns on a spinning frame.

Servo Controller for Carding

At present, the producing line equipment, both in appearance and internal quality, has made great progress. You can find fine grasping ability, more humanized design, friendly man-machine interface, and more convenient operation and maintenance on modern textile producing machinery.

Sound, light, electricity, gas, frequency conversion drive technology, advanced servo system and other new technologies, new carding theory are widely used in the design and manufacturing of the carding production line.

This promotes the producing line developing at a direction of high yield, high speed, energy saving, high quality. Stability and reliability of production have improved.

In addition, the whole producing process can run synchronously, continuously and smoothly. It controls the unevenness rate of the length of the sliver, the knot content and the impurity rate of the sliver stably within a certain range, so as to ensure the quality of raw materials in the later producing process.

Figure 2: A carding machine installed with a servo system.

Servo Controller for Drawing Frame

With the continuous improvement of the requirements of spinning production, it is very important to apply the self-leveling technique in a drawing frame.

With servo controller, the drawing frame can automatically and effectively detect the unevenness of the sliver and adjust the draft ratio in real time, therefore to effectively control the quality of the output sliver. But this control system still has a large room for improvement.

With servo motor and digital closed loop control technology, FA387 drawing frame realizes stepless adjustment and dynamic monitoring of main draft.

The minimum draft multiple can be adjusted within ±0.01 times and the weight control precision can reach 0.05g/ (5m). The quality of sliver is stable and the operation is reliable. Its advanced electronic control and automation technology efficiently reduce the power consumption and running noise of the drawing machine. What’s more, it works with easy operation and maintenance, and can reduce 4 to 8 repair workers for producing 1 million ingots and save about 200 thousand yuan annually.

Figure 3: Servo system works for drawing frame.

FA398A drawing frame adopts computer control, servo drive, frequency control, sensor detection and other advanced electronic technology, realizing the whole process of auto leveling of short segments controlled by open loop and real-time control of sliver. When different varieties are tested under the conditions of different speeds, all can achieve stable control, good even effect, and improve the quality of sliver. The control schematic diagram of the auto leveler system with open-loop control is shown below.

Figure 4: Auto leveller system with open-loop control works in a drawing machine.

Servo Controller for Roving Frame

In the roving frame with multi-motor drive system, the draft roller, spindle wing, bobbin and bar are driven by independent servo motor respectively, and the synchronous coordination of multi-motors is completed by a high-precision control system.

Adopting servo control of servo control system can effectively solve multiple motor synchronous control problem in the process of the starting, dynamic and parking. With a servo controller, detail defects in the process of turning on and off the roving frame can be eliminated too. At the same time, it cancels pressure arm & foot and differential gear simplifying the maintenance work. What’s more, the servo controller can help to save energy and reduce noise and vibration.

Project Discussion and Feasibility Analysis of New Type Wing-Guided Roving Frame studied a new type of wing guide winding of high-speed roving frame based on servo control system. The tubular guide winding method has been developed and mature, but due to its own limitations, it is difficult to further improve the spinning speed and yarn quality. However, under the current technological conditions, the disadvantages of wing guide can be overcome, and its advantages can be displayed, thus providing a new idea for the development of roving frame.

Figure 5: A roving frame which has servo system.

Servo Controller for Spinning Frame

Servo system is composed of the controller, drive, motor and sensor, and mainly used in the collective doffing spinning frame system. The traditional frame of spindle, roller and ring rail lifting depend on main motor drive. The main motor mostly uses two-speed motor, the slower motor is only used for starting, the higher one is used in normal operation, and the breaking rate is high in the spinning process.

With the development of microelectronics and computer technology, the application of programmable controller, AC servo controller and network technology in the spinning frame control simplifies the mechanism, improves the precision, helps stabilize the spinning tension, reduces the broken end and hairiness, and greatly improves the production efficiency of spinning frame.

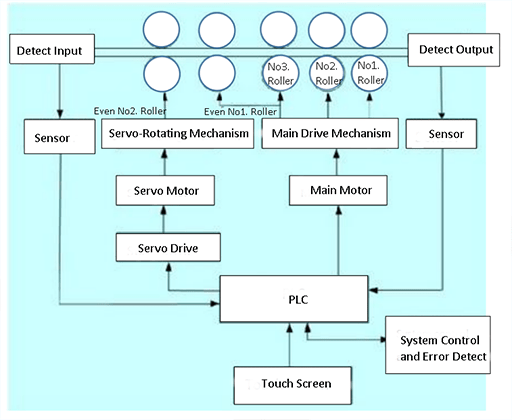

The system mainly includes HMI touch screen, PLC, VFD (variable frequency converter) and servo system. Compared with the traditional transmission mode, the digital draft transmission has a qualitative leap. It has strong anti-interference ability, realizes the precise control of roller speed, and is conducive to the improvement of draft multiple and yarn quality.

Figure 6: Collective automatic doffing device of spinning frame.

Related Info

TECO Servo JSDEP Works for Food Placement MachineBasics of Servo Motor You Should Know

Where is Servo Motor and Servo Drive Used?