Brief discussion on customer value of after-sales service in the life cycle of air compressor

Air compressor life cycle

The life cycle of an air compressor refers to the time elapsed from the time the air compressor is put into use to when it is not suitable for continued use in terms of performance or economy, and then withdrawn from use. In this life cycle, the air compressor either loses its use value due to wear and tear, or is scrapped due to aging, the failure rate increases, the use cost rises sharply, and the economic value decreases.

Different stages of the life cycle

Customers invest in air compressor equipment to obtain value returns in production, but at different stages of the life cycle, due to different operating conditions, the return on value of equipment to customers is different. see picture 1.

Warranty period--During the warranty period, the air compressor has just been put into use. At this stage, the failure rate is relatively high. The reason is mostly due to installation problems, unfamiliar equipment or possible defects in the manufacturing process. Excellent equipment suppliers can provide reliable support services during the warranty period. Therefore, at this stage, the air compressor can provide customers with higher production guarantees and value returns.

Use and operation and maintenance period-once the customer completes the design, selection, purchase and installation of the pre-compressed air system, the air compressor will enter the equipment use and operation and maintenance stage. At this stage, the air compressor is operating stably, but its usage is showing a downward trend with the wear and tear of the power plant, mechanical parts and electrical components. Sudden failure may cause downtime, which affects the continuity of production and the stability of value return. Therefore, preventive maintenance is necessary. Targeted, local conditions, optimization and transformation can also create additional value returns for customers on the basis of normal use.

Replacement and payback period-At this stage, the air compressor enters the aging stage, the failure rate increases, the energy consumption increases, and the customer faces the upgrading of equipment.

Two basic demands of customers in the life cycle

Maximum equipment operation intact rate-a single equipment intact rate refers to the percentage of the normal use of this equipment after deducting failures and shutdowns in 365 days a year. It is the basic basis for evaluating the good operation of the equipment and a measure of the level of equipment management. An important indicator of Every 1% increase in the intact rate means that the number of days of factory shutdown due to air compressor failure will be reduced by 3.7 days. This is of great significance for continuous production enterprises. See Figure 2.

Minimization of Life Cycle Costs-All costs of the user during the period from equipment procurement, installation, maintenance and management to complete disuse of an air compressor are called life cycle costs. Practice has proved that in the cost composition of most customer expenditures, the initial investment of equipment accounts for 15%, the maintenance and management costs during the use period account for 15%, and 70% of the costs come from energy consumption. Obviously, the key point of customers' demand for the lowest life cycle cost of air compressors is effective energy efficiency control. See Figure 3.

How does after-sales service meet the basic demands of customers

In fact, it is an ideal goal to require the highest rate of equipment operation and the lowest life cycle cost. In actual production, customers will strike a balance between achieving the highest rate of equipment operation and the lowest life cycle cost. Customers with different industries, different benefits, and different equipment management concepts have different focuses. Excellent after-sales service providers will make specific analyses based on the different priorities of different customers to help companies achieve their goals.

The improvement of the equipment intact rate-the enterprise that puts forward the highest requirements for the equipment intact rate has the following characteristics: continuous production, high added value of products, and good benefits. Its service requirements are to ensure that the equipment is intact, zero inventory, and a fixed and controllable budget. These users are often large state-owned enterprises, multinational foreign companies, etc. After-sales service providers should provide full responsibility for these customers. The full responsibility service covers the equipment needed during the whole year of use; the standard maintenance content + comprehensive responsibility guarantee + the promise of 99.5% intact rate is the highest level of service guarantee. For those customers who have control requirements for maintenance costs among these users, after-sales service providers should provide standard maintenance content + core component insurance guarantee + commitment of 99% integrity or planned preventive maintenance content + commitment of 98% integrity. Give users a variety of service options.

In addition, the situation of some enterprises is completely different: intermittent production, low added value of products, winning by quantity, unstable benefits, and cost control orientation. Its service requirements are transparent and controllable costs, changing with benefits, equipment integrity requirements, and no shutdown during production. These users are often private companies. After-sales service providers should provide flexible and changeable customized services to these customers. Customized services cover the basic equipment operation guarantee content of the plan + on-time billing service

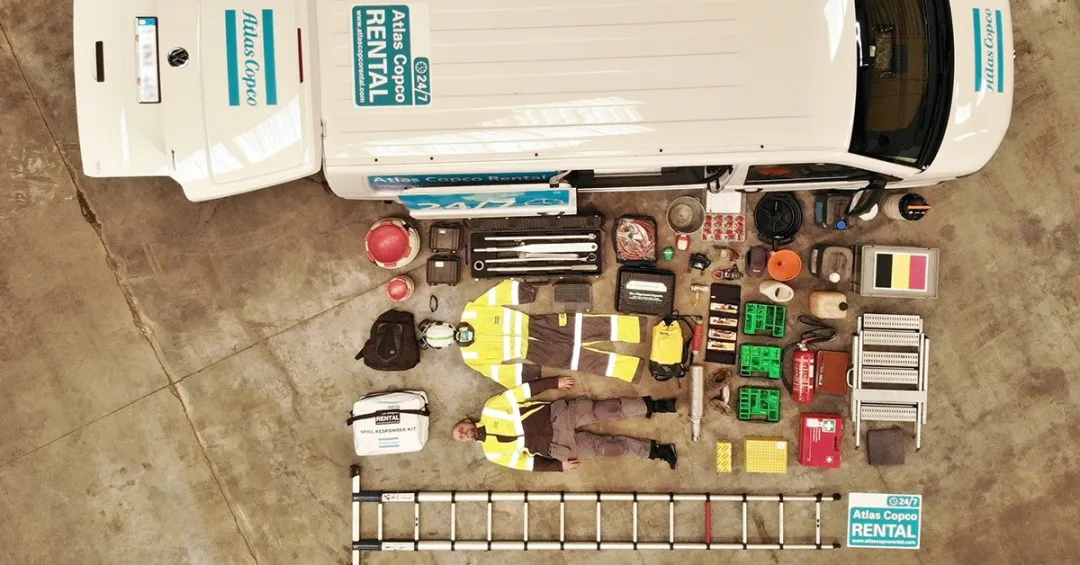

The service provider’s guarantee for the intact rate of the equipment is not mere words, which means that the service provider not only needs to have the ability to provide complete machine quality assurance and core component guarantee, but also must monitor equipment operation data, service personnel scheduling, and the number of service engineers. And skills, logistics and transportation, on-site service quality control form a complete set of after-sales service guarantee system. See Figure 4.

Life cycle cost control---The energy consumption in the life cycle of an air compressor accounts for 70% of the cost. Energy efficiency control is the core of cost control. At present, energy consumption concepts such as "specific power" and "gas-to-electricity ratio" have been widely used in energy efficiency monitoring and control on customer sites. For air compressors that have been installed and used, the control of energy consumption is focused on the later optimization and transformation. For daily use, to meet the requirements of the use of reduced pressure operation, pipeline leakage investigation and leakage is the direction that can be optimized. At the transformation level, first consider using a centralized controller with an energy optimization algorithm to centrally control and optimize the high-power air compressors, low-power air compressors, and variable-frequency air compressors in the entire air compressor station. Operating logic can save energy by 5-10% in general. Secondly, the heat recovery of the air compressor can use waste heat to replace the heat source in the customer's original production process, saving energy expenditure. Thirdly, for the situation that the centrifugal air compressor deviates from the optimal gas use curve and the energy consumption rises due to process changes, users can save a lot of electricity by reducing the pressure of the centrifuge with three stages and changing the three stages to two. When the air compressor enters the final stage of the life cycle, the replacement and payback period of the machine maintenance expenditure will greatly increase, and there is no plan to purchase a new machine, you can consider returning to the factory for refurbishment and remanufacturing; the method will let the old equipment glow with new life and extend Life cycle, reduce use cost. The energy efficiency improvement after returning to the factory for remanufacturing ranges from 5-10%.

in conclusion

The value given to customers by after-sales service during the life cycle of an air compressor is reflected in two aspects. The first is to ensure the safe and stable operation of the equipment. This core measure is the equipment integrity rate. The second aspect is life cycle cost control, which is mainly focused on; energy consumption control, through user production process analysis and gas demand analysis, it is possible to find a variety of ways to achieve energy saving and consumption reduction, and create for users in the use of compressed air systems. More value.