How to achieve zero consumption of compressed air for drainage

This article discusses the working principle of the compressed air zero-consumption automatic steam trap, and gives the most marketable accessory installation sample structure, and the actual energy-saving effect achieved in the actual application of the enterprise. It is easy to maximize the promotion and use to create greater economic and energy-saving effects for enterprises.

1. Working principle of zero gas consumption automatic steam trap

2.

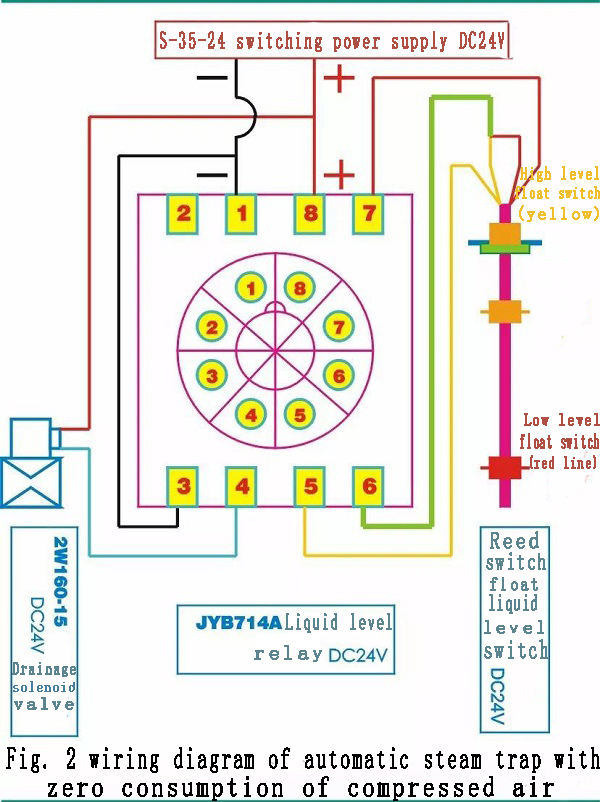

Equipped with S-35-24 switching power supply output DC24V, JYB714A liquid level relay DC24V, 2W160-15 drain solenoid valve DC24V.

Among them, the connection wiring diagram of S-35-24 switching power supply, JYB714A liquid level relay and 2W160-15 drain solenoid valve is as follows:

The liquid level relay 1, 8 terminals are connected to the switching power supply DC24V and the liquid level relay 1, 3 terminals are short-circuited; the two wires of the drain solenoid valve are respectively connected to the liquid level relay 4 and 8 terminals; the high liquid level of the liquid level switch (yellow wire) One connected to terminal 5 of liquid level relay; one connected to terminal 7 of liquid level relay for low liquid level (red wire) of liquid level switch; another yellow wire of liquid level switch connected to another red wire and then liquid level relay 6 Terminal.

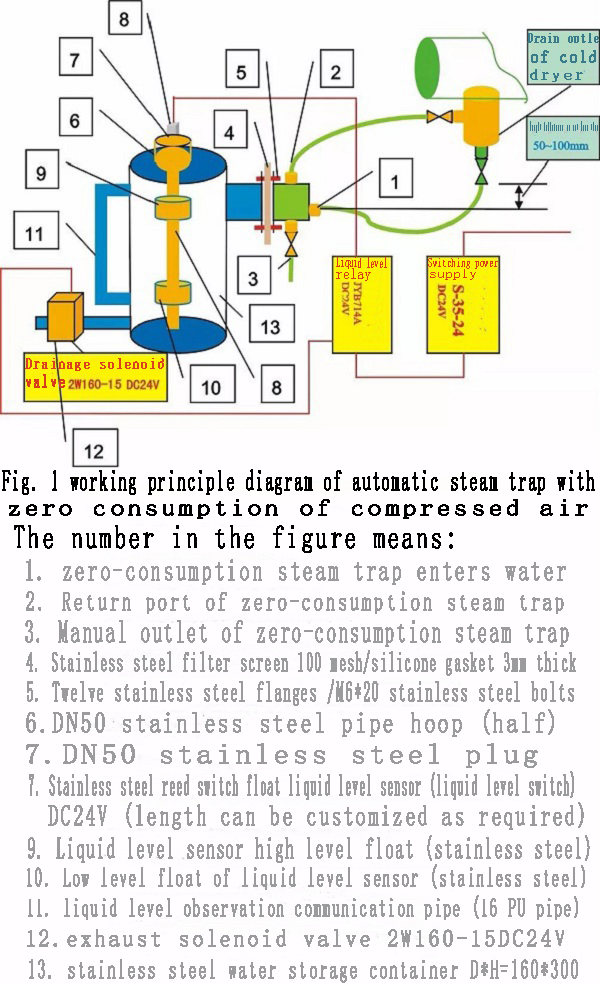

The automatic steam trap for compressed air with zero consumption is mainly composed of three parts:

A. Filter components (No. 1~5): Filter impurities and rust in the compressed air and water medium to prevent the liquid level switch float and solenoid valve from clogging, causing the zero gas consumption automatic steam trap to not work normally;

B Stainless steel water storage container (No. 6, 7, 11, 13): including a connecting pipe for observing the liquid level, which is convenient for judging whether the float of the liquid level switch is operating normally;

C Automatic drainage components (No. 8, 9, 10, 12 and liquid level relay, switching power supply): The liquid level sensor switch sends out high and low level signals, and the drain solenoid valve executes the high level signal to open, and the low level signal Close operation. The liquid level switch, liquid level relay, and solenoid valve all have a life span (the number of actions is 100,000), and they need to be checked and replaced about every six months. They can be replaced in early April and early October each year.

The required current of the stainless steel reed switch float level switch cannot exceed 0.5A, so it needs to be equipped with DC24V direct current voltage, AC220V to DC24V switching power supply, and DC24V drain solenoid valve.

The working principle of compressed air zero consumption automatic steam trap:

The condensate containing compressed air from the drain ball valve under the container of the refrigeration dryer first enters through the inlet of the zero consumption automatic steam trap, and the compressed air is returned from the upper air return port to the upper part of the drain ball valve of the refrigeration dryer. The air return port will not cause the compressed air to stay at the inlet, causing the condensed water to fail to enter the zero-consumption air trap continuously, affecting normal operation.

In order to ensure that the condensed water of the refrigeration dryer flows smoothly into the inlet of the zero consumption trap, the end of the drain discharge ball valve of the refrigeration dryer should be at least 50mm higher than the level of the zero consumption trap inlet, which can be carried out at a height difference of approximately 50-100mm. Installation master.

The condensate of the refrigeration dryer entering the inlet of the zero-consumption gas trap is filtered through a 100-mesh stainless steel filter to filter the particles and rust residues in the water (this requires the air compressor station attendant to manually open the manual drain valve every 8 hours Discharge twice to ensure that impurities, rust and slag are discharged in time). The filtered clean condensate from the refrigeration dryer continues to enter the stainless steel water storage container.

As the water level in the stainless steel water storage container rises, it reaches the high level float action level of the stainless steel reed switch liquid level switch, the liquid level relay sends an open signal to the drain solenoid valve, the drain solenoid valve opens, and the cold dryer condenses water Under the pressure of compressed air, it is discharged from the drain port of the drain solenoid valve. The liquid level in the stainless steel container begins to drop until the low level float of the liquid level switch drops, the liquid level relay sends a signal to the drain solenoid valve to close, the drain port of the drain solenoid valve closes, and the condensation water of the refrigeration dryer stops discharging, but the refrigeration dryer The condensate still continuously enters the stainless steel container. As the liquid level in the stainless steel container rises again, it enters the next action cycle, and so on.

This control process is more complicated, and it is necessary to configure a JYB714A liquid level relay (connect the terminal wiring according to the drainage connection method, see Figure 2 for the wiring diagram of the compressed air zero-consumption automatic steam trap).

2. Use energy saving effect

Through the statistical analysis and calculation of the actual flowmeter, after the centrifugal air compressor refrigeration and dryer is installed with a zero-consumption automatic steam trap, each centrifugal air compressor can save 2.68Nm3/min of compressed air per minute, and three centrifugal air compressors total each Monthly compressed air saving: 2.68times; 3times; 60times; 24times; 30= 347328Nm3.

Based on the company’s average compressed air production cost of 0.14 yuan/Nm3, three centrifugal air compressors can save the company’s compressed air costs per month: 347328times; 0.14=48625.92 yuan; 48,600 yuan.

The annual cost of compressed air can be saved for the company: 4.86times; 12=583,200 yuan.

Because the original steam traps of the refrigeration dryer manufacturers are timed to discharge, how long each discharge and how long is the interval between the two discharges, it is inevitable that the time setting is inaccurate, and exhaust waste will occur. The compressed air zero-consumption automatic steam trap is designed according to the above working principle, and it discharges the condensed water accumulated in the water storage container, and there is no compressed air, so it is called zero-consumption, which determines that the design itself is energy-saving. The company has promoted the use of zero-consumption automatic steam traps in various air compressor stations for more than a year, which has produced huge economic and energy-saving effects for users.

This has laid a good foundation for the company's next step-by-step transformation of the screw air compressor refrigeration dryer and the compressed air drainage discharge of the air storage tank, and will surely create greater benefits for the company's next energy-saving transformation.