Figure 1: High torque stepper motor 12v.

1. How to Increase Stepper Motor Torque

1.1 Method of Increasing Stepper Motor Torque at High Speed

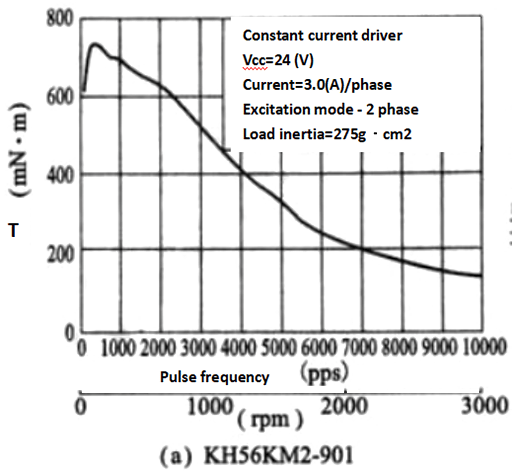

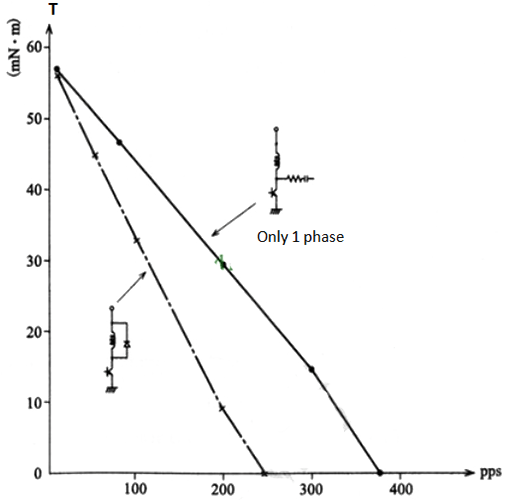

1. Reduce the number of turns to reduce inductance L: select the motor with small inductance L from the standard products of the motor manufacturers, the rated current will increase. The figure below shows a comparison of the speed-torque characteristics of a two-phase HB-type stepper motor with the same input at low speed and different winding turns. At high speed, the larger the rated current, the larger the motor torque. The motor is two-phase, HB type, 1.8 °, 56mm, 54mm long).

Figure 2: Speed-torque characteristics of stepper motor KH56KM2-901..

2. The magnetic flux of the permanent magnet should be small: if the manufacturer cannot reduce the size of the permanent magnet, they can increase the air gap, so that the back EMF can be reduced at high speed, the current can be increased, and the torque can be improved. Therefore the speed-torque characteristic curve can be changed from low speed to high speed into a straight line, the torque at high speed is increased, and the response frequency is also improved.

3.Select a motor with a large step angle: the torque at high speed can be effectively improved.

1.2 Method of Increasing Stepper Motor Torque at Low Speed

1.Select a stepper motor with a small step angle: at low speed, the torque increases with the increase of the number of rotor teeth. Selecting a stepper motor with a small step angle can obtain high torque. In fact, if the number of HB rotor teeth is 50 teeth, the magnetic flux leakage of the magnet will increase, but it will not be proportional. This conclusion is valid under 100 teeth.

The step angle of the three-phase HB type stepper motor changing from 1.2° (rotor 50 teeth) to 0.6° (rotor 100 teeth), will increase the low-speed torque by about 1.4 to 1.8 times.

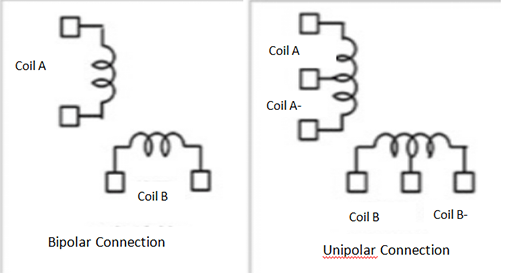

2. Bipolar wiring: the efficiency can be improved by 2 times. It is easy to buy two-phase unipolar or bipolar stepper motors on the market, but the bipolar type has more driving power tubes than the unipolar type.

Figure 3: Comparison between bipolar and unipolar stepper motor.

1.3 Method of Increasing the Torque through the Drive Circuit

1. Increase the voltage of the drive circuit: To maintain the high torque at high speed, the current must be kept unchanged, so that the chopper works in a constant current state. To make the current constant, the pulse frequency can only be increased.

When the output speed of the stepping motor reaches a certain high speed, it can only work in a constant voltage state due to the voltage limitation. If the input voltage is increased, it can still work in a constant current state at high speed, thereby improving the torque at high speed.

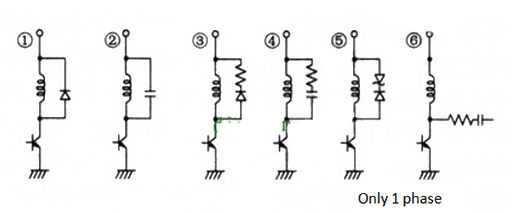

2. Reduce the current of the drive circuit when it is turned off: Because the current in the coil has a large rate of change when the power tube is turned off, a very large induced voltage will be generated in the coil, and the power tube will be in danger of breakdown. Usually there is a protection circuit, and its composition is shown in the figure below. In the figure, ① is the freewheeling diode wiring diagram. When the power tube is turned off, the back EMF generated by the coil forms a current release path through the closed loop composed of the freewheeling diode and the coil.

Figure 4: Power circuits for various drive circuits.

The torque generated by this current in the rotor is opposite to the rotor steering, which is the braking torque, and reduces the dynamic torque. Correspondingly, in ③ a resistor is connected in series in the diode branch to reduce the current that generates the braking torque.

The figure below shows the speed-torque characteristics of the circuits ① and ⑥ in the above figure for the same stepper motor drive. The drive circuit ⑥ adds resistors and capacitors to the freewheeling circuit of phase A and A- to reduce the releasing current. The speed-torque characteristics of circuits ① and ⑥ are very different. From this, it can be seen that the structure of the drive circuit has a great influence on the dynamic torque of the stepping motor.

Figure 5: Comparison of speed-torque characteristics based on drive circuit.

2. Stepper Motors Selection

When choosing a stepper motor, the following parameters can be considered:

1. Number of phases, usually represented by m;

2. Number of beats, usually represented by n;

3. Step angle;

4. Positioning torque;

5. Static torque;

6. Step angle accuracy;

7. Number of steps;

8. Maximum no-load starting frequency;

9. Running torque frequency characteristics, etc.

There are other parameters of the stepping motor that should be considered when choosing, and the above are the important ones. More questions about how to select the stepping motor and how to view the parameters, please feel free to contact our engineers! The following 6 steps will teach you the selection of stepper motors, so as to avoid all kinds of unnecessary troubles caused by wrong selection of stepper motors.

2.1 6-Step Method for Stepper Motor Selection

Step 1:

The holding torque of the stepper motor is equivalent to the "power" of the traditional motor. Of course, they are fundamentally different. The physical structure of the stepping motor is completely different from the ordinary AC and DC motors, and its output power is variable.

Generally speaking, we need to choose which type of stepper motor according to the required torque. Usually, if the torque is below 0.8 N.m, generally choose 28, 35, 39, 42; if the torque is about 1 N.m, it is more appropriate to choose motor 57. When the torque is more than 1 N.m, you should choose a stepping motor with a larger torque such as 75, 85, 86, 90, 110, 130 and other specifications.

Figure 6: 12V DC stepper motor high torque.

Step 2:

At the same time, we should also consider the speed of the motor. Because the output torque of the motor is inversely proportional to the speed. That is to say, when the stepping motor rotates at low speed, several hundred revolutions per minute or lower, its output torque is large, but the torque in the high-speed rotation state (1000 rpm - 9000 rpm) is very small.

Of course, some working environments require high-speed motors, and it is necessary to comprehensively weigh the coil resistance, inductance and other indicators of the stepping motor. Selecting a motor with a slightly smaller inductance when high speed is required, can obtain a larger output torque. On the contrary, in the case of requiring low speed and high torque, it is better to choose the inductance in ten or tens of mH, and the resistance should be larger.

Step 3:

The no-load starting frequency of the stepper motor is generally called "no-load frequency". This is an important indicator for purchasing a stepper motor. If it is required to start and stop frequently in an instant, and the speed is around 1000 rpm or higher, it is best to choose reactive or permanent magnet stepper motors, which have a relatively high "no-load frequency".

Step 4:

Phase number selection of stepper motor. Many customers pay little attention to this content, and most of them buy it casually. In fact, motors with different phases have different working effects. The more the number of phases, the smaller the step angle can be, and the smaller the vibration during operation. In most cases, two-phase, three-phase, and five-phase hybrid stepping motors are used. In the high-speed and high-torque working environment, it is very practical to choose a three-phase stepper motor.

Step 5:

The waterproof and anti-corrosion type stepping motor can be waterproof and oil-proof, and is suitable for some special occasions. For example, underwater robots need waterproof motors. For special purpose motors, it is necessary to select them in a targeted manner.

Step 6:

Customization. If you need stepping motors with special specifications, you’d better communicate with the manufacturer, and let them process it for you within the scope of technology permitted, such as the diameter, length, and extension direction of the outgoing shaft.

If you need a high torque stepper motor, our website, Okmarts is a good choice. We can provide various high torque stepper motors for you to choose from the most satisfying one!

Related Info

Some Common Questions about Motor TorqueSpeed-Torque Curve of Stepper Motors and FAQs

Types of Stepper Motors: Three Methods to Classify

Servo Motor vs Stepper Motor: Comparison from 9 Aspects

Torque Motor: Structure, Features, Types, Application