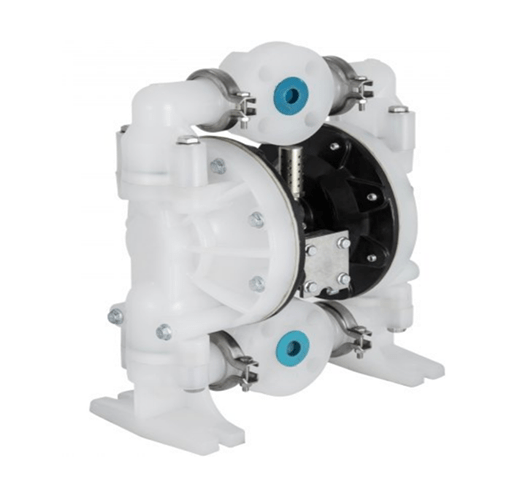

Figure 1: Diaphragm pump.

During the operation of the diaphragm pump, there should be no abnormal sound, and all parts should be free of running, emitting, dripping, leakage and other phenomena.

The pressure gauge and control valve should work reliably, and the performance index can reach the rated capacity of the manual or meet the production requirements. However, due to normal wear and tear or the material of parts, their aging will also cause failures.

1. Insufficient or Increased Pressure of Diaphragm Pump

Figure 2: Some pump may suffer insufficient or increased pressure.

Cause 1. The pressure regulating valve of the diaphragm pump is improperly adjusted.

Solution: Please adjust the pressure valve to the required pressure.

Cause 2. The pressure regulating valve is faulty.

Solution: Overhaul the pressure regulation.

2. Pressure Drop of Diaphragm Pump

Cause 1. Insufficient feeding or leakage of feeding valve.

Solution: Check the feeding condition and feeding valve.

Cause 2. The seal leaks oil.

Solution: Repair sealing components.

Cause 3. The pump body leaks or the diaphragm is damaged.

Solution: Check and replace the gasket or diaphragm.

3. Insufficient Flow of Diaphragm Pump

Cause 1. The air inlet and exhaust valve leaks.

Solution: Repair or replace the intake valve.

Cause 2. The diaphragm is damaged.

Solution: Replace the diaphragm.

Cause 3. The speed is too slow, and the adjustment fails.

Solution: Check the control and adjust the speed.

4. Oil Leakage of Diaphragm Pump

Figure 3: Oil leakage of diaphragm pump.

Cause 1. The gasket and sealing ring are damaged or too loose.

Solution: Adjust or replace gaskets and sealing rings.

Cause 2. The energy-saving water pump can’t show the pressure.

Solution: 1. Reduce pipe resistance and replace the valve.

2. Connect the motor wiring correctly.

3. Remove foreign matters.

5. Serious Wear of Internal Components

Cause: The ball seat and ball valve of diaphragm pump will inevitably be worn after long-term use. If the wear is serious, it will affect the reliability of operation, and the flow will also be abnormal.

Solution: It is recommended to check the operation of the ball socket and ball valve in daily work, deal with the displacement or corrosion of the ball socket in time, and regularly check the wear of the ball socket to maintain attention.

Figure 4: Wear of internal components.

6. Air Pump Does not Work

Cause: Common causes include loose connecting lines, broken lines, serious wear of internal components, etc.

Solution: Check the power supply and lines first, tighten the loose connection points, and replace the seriously worn components in time.

7. Final Thoughts

The above is a introduction to the common faults and treatment methods of the diaphragm pump. On the whole, the incidence of abnormal problems in the actual probability of the diaphragm pump is not high. If you encounter more complex problems, please ask professional staff.

Related Info

What is Diaphragm PumpsCommon Types of Diaphragm Pump

Structure and Working Principle of Diaphragm Pump

Classification of Gear Pump