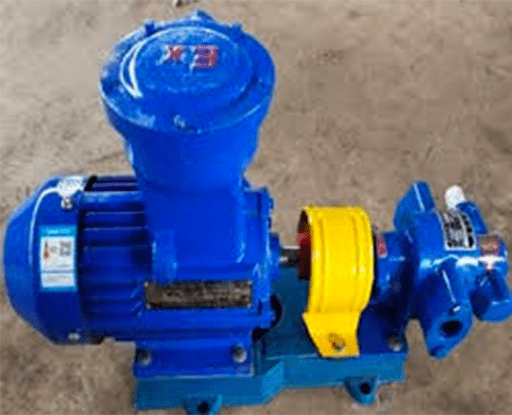

Figure 1: Gear pump.

1. Precautions for Installation

1. Before installing the gear pump, please check whether the pump and motor are damaged during transportation, or dirt enters the pump cavity due to the loss and rupture of the dust cover.

2. The gear pump and motor are installed on the floor. When lifting with a crane, the lifting rope must fall into the lifting ring under the base plate. When lifting the pump head alone, it must be hung under the flange pipe at the inlet and outlet, so that the pump oil will not bear external forces.

3. Before installing the inlet and outlet pipe of gear pump, the inner wall of the pipe must be flushed with kerosene. No sundries, especially friction substances, are allowed to remain in the pipe. If such substances enter the pump body, the gear will be damaged. The inlet and outlet pipe diameter of the pump should not be smaller than the inlet and outlet pipe diameter of the pump. The inlet pipe should adopt a slightly larger pipe diameter. The shorter the inlet pipe is, the better it is. The elbow should adopt a larger bending radius. The valve of the pipeline should adopt a gate to reduce resistance.

4. The gear pump should be fixed on a solid foundation to avoid loosening and vibration of pipes. And it should be fasten with bolts to avoid floor deformation. If a separate pump head is installed on the machine, it must be placed in a place with low vibration.

Figure 2: The gear pump should be fixed on a solid foundation.

5. The gear pump shall be installed in a dry and bright place, so that the management personnel can check the operation of the gear pump. If the pump must be close to the wall device, an open space must be reserved. It is convenient for disassembly and maintenance. Don't put it in a place that is damp, exposed to the sun, and exposed to the wind and rain. If there is any possibility of flooding in the installation site, the installation elevation of gear pump must be above the highest water level.

6. The pump body and motor shaft should be installed concentrically. If the installation concentricity is not good, the coupling may be damaged during rotation.

Figure 3: A coupling of the gear pump.

7. There is no need to install the bottom valve for the gear pump. However, due to the great resistance of the bottom valve, it is recommended to install a metal filter screen at the inlet of the oil inlet pipe to prevent sundries from entering the pump body. The effective area of the oil filter screen should be greater than twice the area of the pipe diameter, and the oil suction port of the oil inlet pipe should be cut into a 45 ℃ angle.

2. Installation Judgment

Figure 4: Install the gear pump carefully.

1.In order to prevent sundries from falling into the machine during installation, all holes of the whole machine should be covered.

2.In order to prevent the sundries in the pipeline from entering the pump, a filter should be set for the newly installed pipeline, and the effective load surface should be 2-3 times larger than the load surface of the suction pipe.

3.Place the whole machine on the foundation with embedded foundation bolts, and calibrate it with rubber pads between the base and the foundation.

4.Loosen the coupling, place the level on the pump shaft and base respectively, adjust the rubber pad to correct the level of the whole machine, and properly tighten the anchor bolts to prevent walking.

5.Correct the concentricity of the pump shaft and motor shaft, and ensure that the gap between the two couplings is 2-4 mm. The tolerance is 0.3 mm.

6.After connecting the pipeline and determining the rotation direction of the motor, connect the coupling, and then correct the concentricity of the shaft.

After 2-3 hours of trial operation of the whole machine, make the final inspection. If there is no bad phenomenon, it is considered that the installation is qualified.

Related Info

Common Faults of Gear PumpHow to Repair Gear Pump

What is a Gear Pump

Classification of Gear Pump