Condenser cleaning judgment, method and operation are all here!

"Condensers are prone to scale formation in the pipes after long-term use. If they are not treated in time, these scales will affect the heat exchange effect and cause the condensing temperature of the unit to increase, which in turn will reduce the cooling capacity and increase the power consumption of the unit. Therefore, the condenser should be cleaned frequently."

1. Calculation of the temperature difference of the condenser

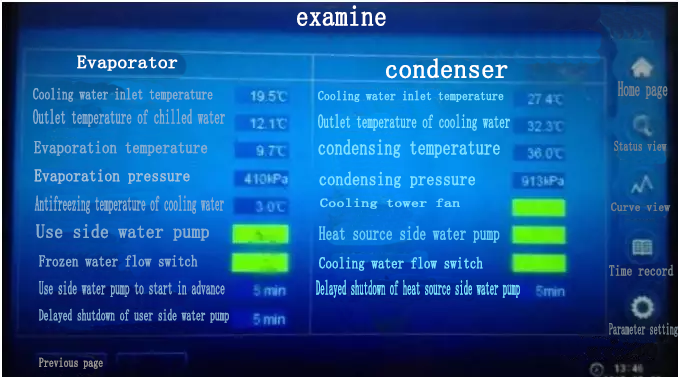

The focus of condenser cleaning is to pay attention to: chilled water inlet and outlet temperature, cooling water inlet and outlet temperature, condensation pressure, evaporation pressure. We can calculate the end temperature difference and convert the condensation pressure and evaporation pressure into the corresponding condensation saturation temperature and evaporation saturation temperature. If the condensation temperature and evaporation temperature can be queried on the touch screen, this value is the corresponding condensation saturation temperature and evaporation saturation temperature. As follows:

If the calculated end temperature difference is greater than 5°C, it can be preliminarily judged that the heat exchanger has scaled. When the end temperature difference is greater than 7°C, the scale will be serious.

Example: Condensing end temperature difference = 36°C-32.3°C = 3.7°C, evaporation end temperature difference = 12.1°C-9.7°C = 2.4°C, it can be seen that the condensation end temperature difference and the evaporation end temperature difference are both small, the shell and tube heat exchange effect is better, basically no Scaling. As shown below:

In addition, you can also look at the color of the copper tube of the condenser. If you can't see the original color of the copper tube, the scaling is already serious and you need to clean it in time.

Two, the main method and operation of condenser cleaning

There are three main methods for removing scale from the condenser:

Mechanical descaling

Chemical pickling and descaling

Electronic magnetic water descaling method

Below we introduce these three cleaning and descaling methods.

1. Mechanical descaling:

Mechanical descaling is to descale the condenser of the cooling tube with a flexible shaft tube washer (commonly known as a gun machine), which is suitable for vertical shell and tube condensers. (Speaking of this, the editor can't help but think of the scene of many years ago when I held the gun barrel in my hand and cleaned the condenser manually.)

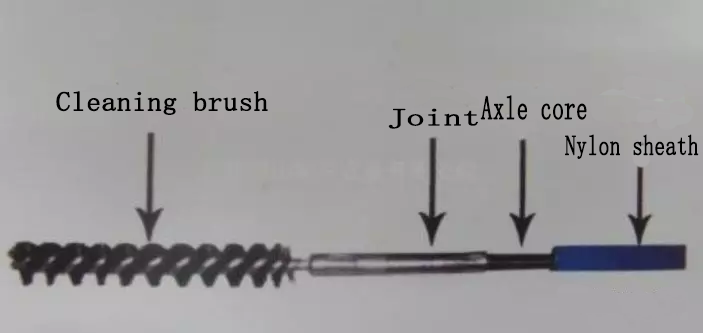

Principle and method of flexible shaft tube washer:

The bevel gear-shaped scraper connected to the flexible shaft tube washing device rotates and removes the scale from top to bottom in the stand pipe of the condenser, and uses circulating cooling water to cool the heat generated by the friction between the scraper and the pipe wall, and remove the Flush dirt and rust into the pool.

causIn the descaling process, pay attention to the thickness of the condenser and the degree of rust on the tube wall, and the length of years it has been used to determine the appropriate diameter of the hob, and the hob to be used in the first descaling The diameter should be appropriately smaller than the inner diameter of the cooling pipe to prevent damage to the pipe wall, and a hob close to the inner diameter of the cooling pipe is used for the second descaling.

2. Chemical pickling and descaling:

The chemical pickling and descaling method is suitable for vertical and horizontal shell and tube condensers (steel pipes). During the descaling process, the normal operation of the condenser must be stopped to ensure safety.

Principle and method of chemical pickling and descaling:

Clean the condenser with the prepared weak acid scale remover to make the scale fall off.

Close the inlet valve, outlet valve, balance pipe valve, mixed gas valve, oil drain valve and other valves on the condenser to stop the condenser cooling water pump.

Prepare the descaling solution in the pickling tank, start the pickling pump, make the descaling solution circulate in the condenser tube for 24 hours, check the scale shedding, and then determine whether to continue cleaning, generally after 24 hours The scale is basically removed. After stopping the pickling pump, wash the descaler solution remaining in the pipe with clean water repeatedly until it is completely clean.

3. Electronic magnetic water descaling method:

The electronic magnetic water descaling method is suitable for various condensers, and descaling and preventing scaling without affecting the normal operation of the refrigeration system. And this method can not only effectively prevent the generation of new scale, but also remove the original scale.

The working principle of electronic magnetic water device:

The calcium, magnesium and other salts in the cooling water flowing through the condenser are dissolved in the water in the state of positive and negative ions at room temperature. When the cooling water flows through the transverse magnetic field of the magnetic water device at a certain speed, the dissolved calcium and magnesium Plasma obtains induced electric energy to change its charge state, and the electrostatic attraction between ions is disturbed and destroyed, which loosens the structure of the crystal and becomes loose sludge which is discharged with the flow of cooling water.

The above three cleaning and descaling methods, the descaling method of the electronic magnetic water heater is simple and easy, low labor intensity, not easy to damage the tube wall in the condenser, and can be performed at any time. The normal operation of the refrigeration system should be stopped during pickling and descaling and mechanical descaling, and should be arranged during the off-season.

Note: Mechanical descaling method and chemical pickling descaling method. After cleaning, the condenser must be tested for air tightness (air pressure 1.8Mpa) to check whether the condenser tube is damaged during the descaling process. And the leakage caused. After checking and confirming that the condenser is normal, the air in the condenser can be drawn out (vacuum) and put into normal operation.