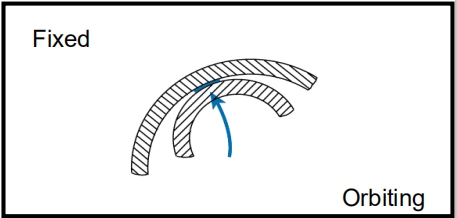

Danfoss H series scroll compressor flexible sealing technology The scroll compressor is a positive displacement compressor, and the compression component is mainly composed of a movable scroll and a fixed scroll. The scroll compressor was first born in 1905 and was invented by the French engineer Leon Creux. Due to the relatively backward mechanical processing technology at that time, it was not until the early 1980s that the scroll compressor began mass production. At present, there are many producers of scroll compressors, mainly Danfoss, Daikin, Dalian Panasonic, Copeland and so on. With the continuous improvement of energy efficiency standards at home and abroad, major producers have invested a lot of money in technology, and various upgrade and optimization schemes and new technologies are emerging. Danfoss has won wide acclaim in the refrigeration, heating and other industries with its excellent technology, super high quality and service. All types of compressors have a problem that must be solved, that is, the leakage of refrigerant in the compression chamber. The refrigerant leakage channels in the compression chamber of the scroll compressor mainly include axial leakage and radial leakage. Axial leakage refers to refrigerant leakage at the end surface contacting the dynamic and static scrolls, and radial leakage refers to dynamic and static leakage. Leakage at the curved surface where the scroll disk contacts. If the contact between the dynamic and static scrolls is too close, despite the lubrication of the oil film, the friction force generated by the end and the curved surface of the contact between the dynamic and static scrolls will be too large. A part of the power of the compressor motor is used for friction heat generation , The motor efficiency is low, and it may also cause the compressor exhaust temperature to be too high, the lubricant is easily deteriorated, carbonized, and the compressor energy efficiency ratio is low. Conversely, if the gap between the movable and stationary scrolls is too large, the refrigerant leakage is too large, and the pressure ratio and motor efficiency will also be very low. In this regard, Danfoss innovatively applied flexible sealing technology to Performer H series scroll compressors. The so-called flexible sealing technology includes axial flexible sealing and radial flexible sealing. The movable scroll of the scroll compressor using this technology can move up and down, left and right. The following is a brief explanation for everyone. Axial flexible seal: The principle of axial flexible sealing of Danfoss scroll compressor dynamic and static scrolls is simple. When the compressor is not started, the movable and static scrolls are completely separated, as shown on the right.

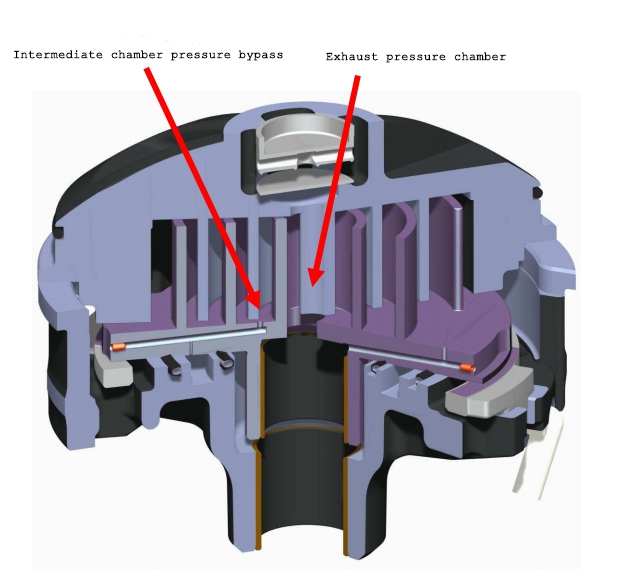

The advantage of this design is that when the compressor is started, the refrigerant pressure has not risen since the fully enclosed compression chamber has not been formed. The compressor is equivalent to starting without load, so the starting current of the compressor is relatively small. The impact is small. When the orbiting scroll turns up, the refrigerant flows and the refrigerant starts to be compressed. At this time, a small hole is opened in an intermediate cavity of the movable scroll to guide the refrigerant pressure in the intermediate cavity to the lower portion of the movable scroll, so that the pressure of the refrigerant in the compression chamber, the gravity of the movable scroll, etc. The resultant force F1 is less than the upward resultant force F2 generated at the lower part of the movable scroll. The movable scroll is held up and contacts the stationary scroll to form a closed compression chamber, and the refrigerant is normally compressed.

The key to the axial sealing technology lies in the location of the small holes, the size and number of the holes, etc. This not only requires rigorous design calculations and rich development experience, but also requires a lot of actual measurement tests to find the best opening position, aperture and number. Radial flexible seal: Compared to axial flexible seals, radial flexible seals are simpler. After the compressor is started, the rotor carries the crankshaft, and the crankshaft quickly rotates with the movable scroll, and the movable scroll is movable. Ground together, plus the role of oil film to form a closed compression cavity