Danfoss "Lighthouse Factory"-Tianjin "Smart Manufacturing" New Business Card

The World Intelligence Conference is approved by the Chinese government and is approved by the National Development and Reform Commission, the Ministry of Science and Technology, the Ministry of Industry and Information Technology, the State Administration of Radio and Television, the National Internet Information Office, the Chinese Academy of Sciences, the Chinese Academy of Engineering, the China Association for Science and Technology and the Tianjin Municipal People A global conference on smart technology jointly organized by the government. It has been successfully held three times since 2017, and has become the world's top event for academic exchanges, exhibitions, open innovation, and deepening cooperation in the field of intelligent technology. During the Third Congress, Chinese President Xi Jinping personally sent a congratulatory letter, proposing to build a platform for communication, cooperation, win-win and sharing through the World Intelligence Conference to promote the healthy development of a new generation of artificial intelligence and better benefit the peoples of the world. The 4th World Intelligence Conference is now held in Tianjin from June 23 to 24, 2020. "Intelligent Conference" Exploring Danfoss Lighthouse Factory

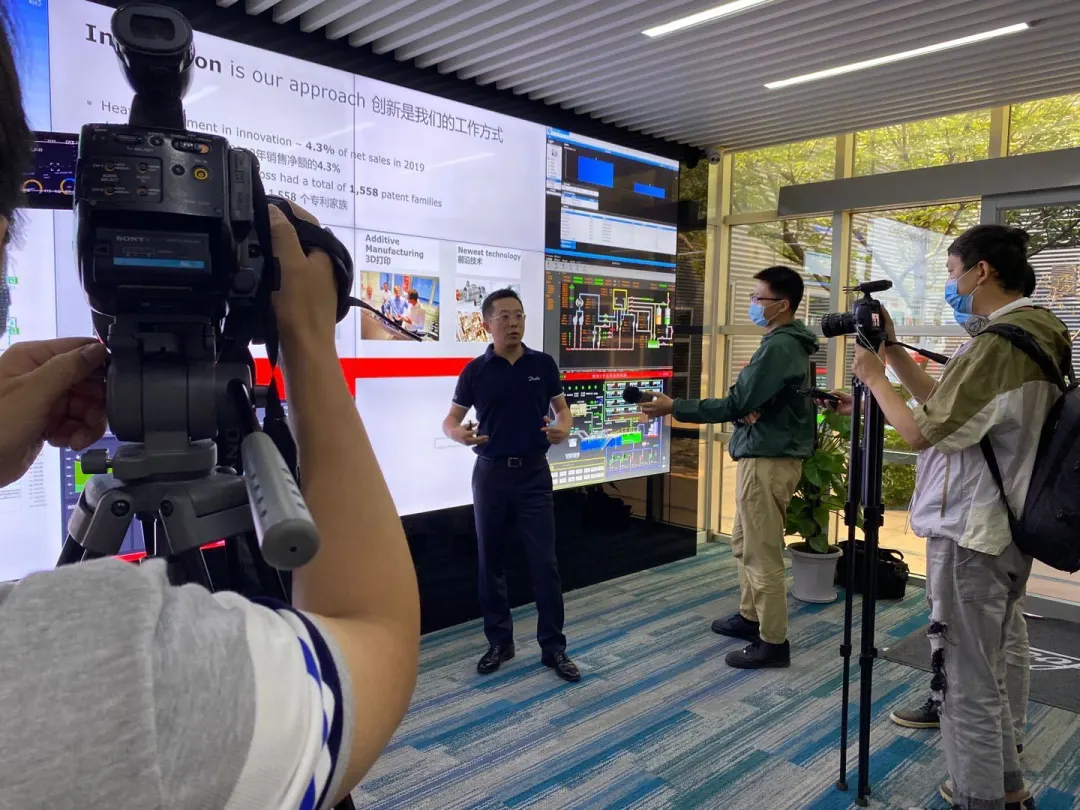

Focusing on the theme of the 4th World Intelligence Conference-New Era of Intelligence: innovation, empowerment, ecology, combined with the cutting-edge development trend of the intelligent technology industry, global market insights, exhibiting technologies and products, the official cooperative media of the conference China Daily, Tianjin Daily, Tianjin TV Station Nearly 30 people including well-known media visited Danfoss (Tianjin) Co., Ltd. and the lighthouse factory and interviewed Mr. Shi Jun, the vice president of Danfoss China and the head of the refrigeration department. In 2019, the Danfoss Tianjin Commercial Compressor Factory was rated by the World Economic Forum as the “Lighthouse Factory" leading the intelligent manufacturing of the fourth industrial revolution. The World Economic Forum commented: “The Danfoss Commercial Compressor Tianjin Plant successfully improved the quality control system with digital tools such as a full digital traceability system, smart sensors, visual inspection, and automatic monitoring systems, increasing labor productivity by 30% within two years. Customers The complaint rate has been reduced by 57%." The fourth industrial revolution advanced lighthouse factory evaluation project is led by the World Economic Forum and assisted by McKinsey. Its macro objective is to help advanced and emerging economies achieve technological upgrading and transformation, overcome practical challenges in the industry, and government, academia , Technology pioneers and civil organizations can better support and build a good ecosystem and learning platform to enable rapid replication of technology and cross-industry dissemination. So far, the World Economic Forum's global "Lighthouse Factory" network has 44 members, 12 of which are located in China. The large number demonstrates the strong improvement of China's manufacturing level. Danfoss is fortunate to be a typical representative among them. In the future, Danfoss will continue to work with partners to promote the improvement of China's manufacturing level. Vice President of Danfoss China, Head of Refrigeration Division Mr. Shi Jun introduces Danfoss to media friends

Looking forward to the future of Danfoss "smart manufacturing"

Construction of a world-class refrigeration business R&D and testing center in Wuqing Danfoss steadily implements the specific measures of "in China, for China", will promote the implementation of our "Created in China" strategy, and build Wuqing into a world-class refrigeration business R&D and testing center. Danfoss will vigorously introduce high-end talents in the Internet of Things, structural design, engineering simulation, and additive manufacturing from the outside. On the other hand, we will increase the cultivation of talents within the company, and cooperate with universities and research institutions such as Tianjin University and Hebei University of Technology. Targeted training of internal technical experts. At the same time, Danfoss will cooperate with internationally renowned software companies to establish a multi-physics coupling simulation system of structure, fluid, electromagnetic and thermodynamics, and use the most advanced technology to form digital design, intelligent simulation, sample additive manufacturing (3D printing), remote operation monitoring And maintenance (LOT) full life cycle digital R&D. In addition, the R&D center laboratory focuses on research and development of test technologies such as scroll compressor technology, inverter motor technology, new refrigerant application technology and heat pump technology. At the same time, in order to continuously adapt to market development needs, the center is also committed to research and development of multi-link technology and intelligent fault diagnosis and control technology.