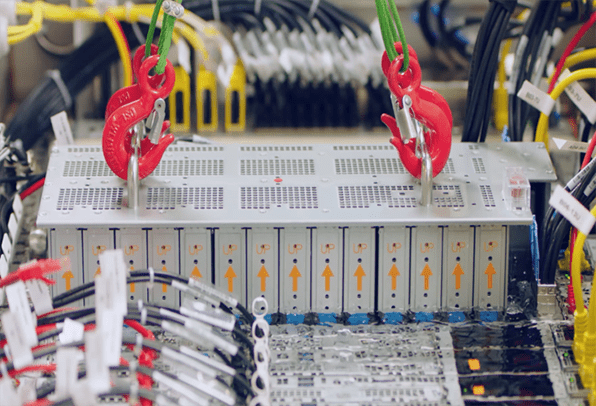

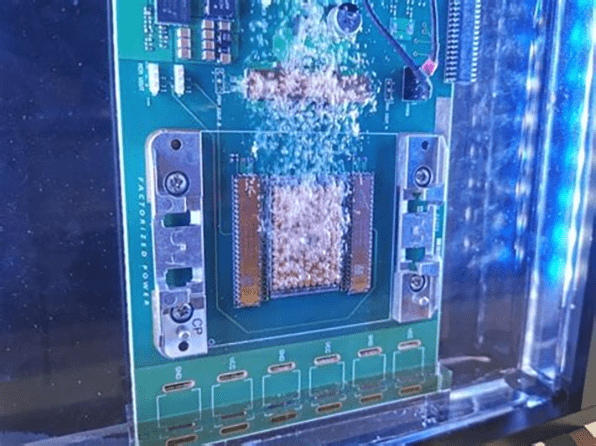

Figure 1: liquid immersion cooling system.

With the explosive growth of data volume, the diversity and complexity of data will lead to a gradual increase in the computing power density of general-purpose CPUs. The application of high-power-density servers also provides opportunities for the large-scale application of liquid cooling technology.

1. Types of Liquid Cooling System Technologies in Data Centers

Liquid cooling technology refers to the technology that uses liquid instead of air as the cooling medium to

dissipate heat from the heating components of the server.

Liquid cooling technology is divided into direct liquid cooling and indirect liquid cooling according to the cooling

method. The typical representative of direct liquid cooling is immersion liquid cooling and spray liquid cooling,

and the typical representative of indirect liquid cooling is cold plate liquid cooling.

According to whether the cooling medium undergoes phase change, it can be divided into single-phase cooling

(non-phase change type) and multi-phase cooling (phase change type, two phase type).

Single-phase cooling mainly uses the temperature difference of the cooling medium to exchange heat, and uses its

temperature rise to remove heat. There are mainly single-phase immersion and single-phase cold plate types.

Multi-phase cooling mainly uses the latent heat of vaporization of the cooling medium to remove heat. The main

representatives are heat pipe cold plate type and multi-phase immersion type.

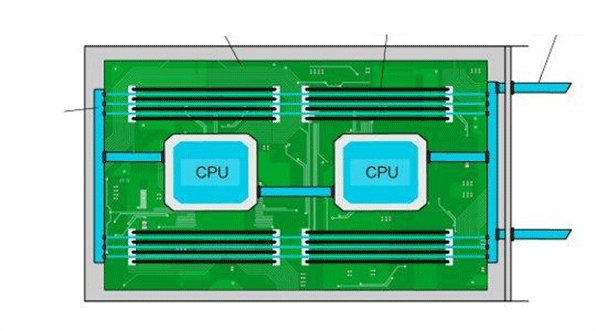

1.1 Cold Plate Liquid Cooling

Cold plate liquid cooling is also called indirect liquid cooling, that is, the coolant and the object to be cooled are separated and do not come into direct contact. The heat of the object to be cooled is transferred to the coolant through efficient heat transfer components such as cold plates. Generally, cold plate liquid cooling is only used to cool key components such as CPU and memory whose heat generation accounts for only about half of the total. Therefore, it also needs to be combined with air cooling to dissipate heat, which can reduce the number and power consumption of IT equipment's built-in fans and achieve a large degree of energy saving.

Figure 2: Cold plate liquid cooling system structure diagram.

One of the cold plate liquid cooling is full liquid type and the other is air liquid type.

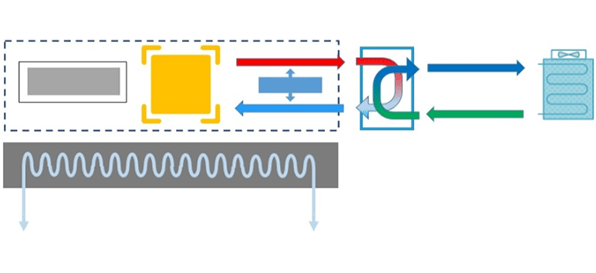

Air Liquid Type

Air-liquid cooling mainly uses liquid cooling for the main high-heat-density heating elements in the server, and

uses air-cooling for low-heat-density heating elements. The cooling method that combines air cooling and liquid

cooling also requires an air-cooled air conditioner in the main computer room.

Figure 3: Cold plate liquid cooling--air liquid system structure diagram.

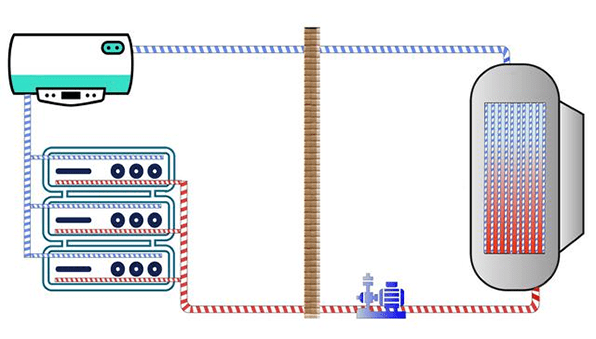

Full Liquid Type

The all-liquid type means that all heating elements in the server exchange heat through liquid cooling. There are

two main ways. The first way is that the heat of all heating elements in the server is transferred through a cold

plate. The design of this cold plate must match the server. The second way is to cool down by setting up a

liquid-cooled back panel door in a cold plate type, and it is generally set at the outlet of the thermal controller

of the rack. Through combination, it can minimize the installation of indoor air-cooling air conditioners.

Figure 4: Cold plate liquid cooling -- full liquid system structure diagram.

1.2 Immersion Liquid Cooling

Immersion liquid cooling is divided into phase change immersion liquid cooling (two phase type) and non-phase change

immersion liquid cooling (single phase type) according to whether phase change occurs during the heat exchange

process.

Single-Phase Immersion Type (Liquid State)

In single-phase immersion liquid cooling, the electronic fluoride remains in a liquid state. The electronic

components are directly immersed in a dielectric liquid, which is placed in a sealed but easily accessible

container, and the heat is transferred from the electronic components to the liquid. The heated electronic fluoride

is conveyed to a heat exchanger by a circulation pump, where it is cooled, and then circulates back to the

container.

system structure diagram-min.png)

Figure 5: Single-phase immersion liquid cooling system structure diagram.

Two-Phase Immersion Liquid Cooling (Liquid and Gas State)

In two-phase immersion liquid cooling, the heat transfer efficiency of the liquid is exponentially improved through

the boiling and condensation processes of the electronic fluorinated liquid. The electronic components are immersed

directly in the dielectric liquid in a container that is airtight but easy to operate. Inside the container, the

heat is transferred from the electronic components to the liquid and causes the liquid to boil and then become

steam. The steam condenses on a heat exchanger (condenser) inside the container, transferring heat to the

circulating cooling water.

system structure diagram-min.png)

Figure 6: Two-phase immersion liquid cooling system structure diagram.

1.3 Spray Liquid Cooling

Spray liquid cooling is deployed for some local IT equipment with particularly high heat generation, and can perform local cooling more accurately. The spraying liquid is in direct contact with the device to be cooled, so the cooling efficiency is high. However, when the liquid encounters high-temperature objects during the spraying process, it will drift away and evaporate. The mist droplets and gases will be emitted to the outside of the chassis along the holes and gaps in the chassis, causing the cleanliness of the computer room environment to decrease or affecting other equipment.

Figure 7: Spray liquid cooling structure diagram.

2. Comparison of Three Liquid Cooling System Technologies for Data Centers

The table below compares cold plate, immersion and spray type liquid cooling systems.

Table 1: Comparison of three liquid cooling methods.

3. Types of Liquid Cooling System Coolant

1. Mineral oil

Mineral oil is a cheap and fine coolant. Single-phase mineral oil is non-toxic, odorless, not volatile, but it has

high viscosity, and easily forms residues on the surface of equipment. Although the ignition point is high, it may

still burn under certain conditions.

2. Fluoride liquid

The biggest feature is insulation and non-flammability. It is the safest and currently the most widely used in data

center liquid cooling technology, but it is expensive.

3. Water

It mainly refers to deionized water. Water has a high specific heat capacity, and is a good heat dissipation medium,

cheap, environmentally friendly and compatible with existing systems. However, since water is a non-insulator, it

can only be used in non-direct contact liquid cooling technology. Once leakage occurs, it will cause fatal damage to

IT equipment.

Figure 8: Mineral oil to cool servers.

4. Advantages of Liquid Cooling Data Center

Based on liquid cooling technology, the construction of a liquid-cooled data center can achieve year-round natural

cooling of the data center without the need for high-energy-consuming equipment such as precision air conditioners,

reducing the PUE value to within 1.1, minimizing the impact on the environment, and achieving the purpose of

efficiency and environmental protection. The advantages of liquid cooling technology mainly include:

• Energy saving and consumption reduction: cooling energy consumption is reduced by 90%-95%; IT equipment energy

consumption is reduced by 10%-20%.

• Cost saving: The construction cost TCO is lower than that of traditional computer rooms.

• Easy site selection: There are fewer environmental restrictions, and the PUE better meets environmental and

low-carbon requirements.

• Safe and reliable: Coolant can improve the operating environment of IT equipment and make it safer and more

reliable.

• Low carbon and green: It reduces the consumption of power resources, and the PUE can be close to 1.0.

Figure 9: Server panel immersed in coolant, with bubbles constantly emerging.

5. Conclusion

The high-efficiency cooling effect of liquid cooling technology effectively improves the efficiency and stability of servers. More servers can be integrated in a unit space, improving the computing efficiency of the data center. It also has the advantages of reduced noise and failure points by reducing or eliminating fans. And the waste heat utilization can also create more added value for the data center. It is believed that liquid cooling technology will become one of the important development trends of data centers in the future.