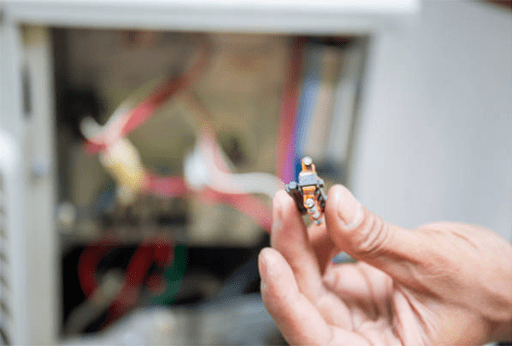

Figure 1: A broken contactor.

1. Excessive Noise

Cause: The short-circuit ring of AC contactor is broken or the end faces of dynamic iron cores and static iron cores are uneven; Skewed or dirty.

Method: Remove the coil, flatten or grind the pole surface of the iron core, or clean the oil stain with gasoline. If the short-circuit ring is broken, replace the scrap iron or contactor. If the iron core is skewed, it should be corrected or fastened.

2. The Contactor Core Cannot be Closed

Causes: The working coil voltage of the contactor is too low; The control circuit is wrong; The coil is broken or burned; The mechanical part of the armature is inflexible or the moving contact is stuck; The auxiliary contact is loose or the card slot is stuck.

Method: If the voltage is too low, the contactor will frequently turn on and off. Please check the control power supply or control circuit and adjust the voltage to reach the normal value:

Figure 2: Check the contactor.

1. Check the voltage at both ends of the contactor coil.

If there is no voltage, check the control circuit or replace the damaged electrical components;

2. Replace the coil or contactor.

If it is caused by an external fault, please eliminate the external fault.

3. Repair the mechanical failure of the contactor.

Remove rust and add some lubricating oil at the mechanical action.

4. Check whether the auxiliary contact is loose and installed in place.

If the movable card slot is worn, replace the auxiliary contact.

3. The Contactor Core is Released Slowly or Cannot be Released

Figure 3: Clean the contactor with gasoline.

Cause: The residual magnetism or the dirt on the end face of the iron core makes the dynamic iron cores and static iron cores stick together. The non-magnetic gasket of DC apparatus is damaged which makes the minimum air gap smaller after the armature is closed.

Method: If there is dirt on the end face of the iron core, clean it with gasoline. If the non-magnetic gasket of DC electromagnetic is damaged, replace the gasket or contactor directly.

4. Contact Overheating and Burning

Cause: The contactor starts too frequently or the contact capacity is not enough; Three phase contacts cannot be contacted synchronously; Impurities or unevenness on the contact surface; Uneven wear of contact surface.

Method: If the contact is overheated and burned, please polish it or replace the contactor contact (you can also replace the contector if you can afford it). Otherwise, it will cause contact adhesion or overheating and fusing resulting in short circuit or phase loss of the main circuit. If the capacity of the contactor is insufficient, please replace it.

5. Contact Fusion Welding

Figure 4: Replace the contactor.

Cause: The high position caused by serious arc will make the contact surfaces of dynamic and static contacts melt and welded together, which can not be broken. The phenomenon of contact fusion welding is usually caused by too small contact capacity, damage of contact spring, reduction of initial pressure, short circuit on load side and so on.

Method: Replace the seriously damaged contact or directly replace the contactor.

6. The Contactor Coil is Seriously Overheated or Burnt Due to Smoke

Cause: Coil short circuit; Insulation aging; The power supply voltage is lower or higher than the working voltage of the coil.

Method: If the coil turns short circuit or insulation aging, please replace the coil or contactor. If the working voltage of the coil is inconsistent with the power supply, please replace the coil whose working voltage is consistent with the power supply voltage.

Related Info

How to select linear guidewaysHow to select the thermal expansion valve

6 Things about your wine cooler notworking