Figure 1: Linear guideways of different models.

Linear guideways are precision transmissions and require careful maintenance in order to give full play to their functions and prolong their service life. The followings are tips for the maintenance of the liner guideway.

1. Prevent Rust.

Before handling the linear guideway directly by hand, thoroughly wash the sweat from your hands and apply high-quality mineral oil before operating. In the rainy season and summer, special attention should be paid to rust prevention.

2. Keep the Environment Clean.

Keep the linear guideway and its surroundings clean. Even tiny dust, invisible to the naked eye, in the guide rail will increase the wear, vibration and noise of the guide rail.

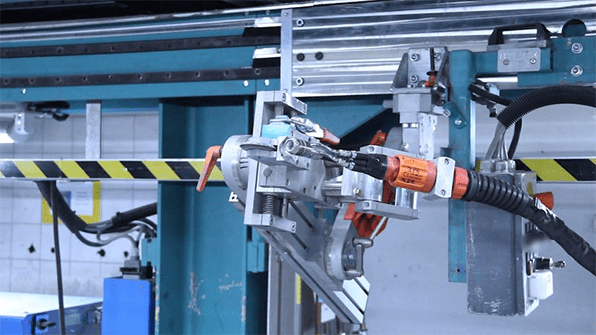

Figure 2: The industrial environment of the linear guideway.

3. Install it Carefully.

The linear guideway should be carefully installed. Avoid strong punching, direct hammering of the guides, and pressure transmission through rolling elements.

4. Use the Right Installation Tools.

Use special tools whenever possible, and try to avoid things like cloth and short fibers.

5、Use Lubricant Properly.

Since the rolling linear guideway requires less oil and has a long oil replenishment period (the oil replenishment period is usually a running distance of more than 100km), there is no problem of guide rail heating at ordinary speeds, so there is no need to force oil supply. Lithium soap grease No. 2 or other high viscosity lubricating oil is recommended.

Figure 3: No. 630-2 NLGI #2, Lithium grease lubricant.

As for the use of grease lubrication, fill the sealed guide rail with grease in advance, or fill an appropriate amount of grease inside the housing, and replenish or replace at regular intervals. In addition, for machines that require lubrication in multiple guide rails, a centralized grease supply method in which pipes are connected to each lubrication point can also be applied. Once the grease lubrication is filled in, it can work without replenishment for a long time. The structure of its sealing device is also relatively simple, so it is widely used. Regular lubrication can greatly improve the life of the guide rail.

Related Info

Classifications of Linear GuidewaysMaterials for Linear Guideways

Top 7 Linear Guideway Brands

The Constitution of a Linear Guideway

How do Linear Guideways Work?