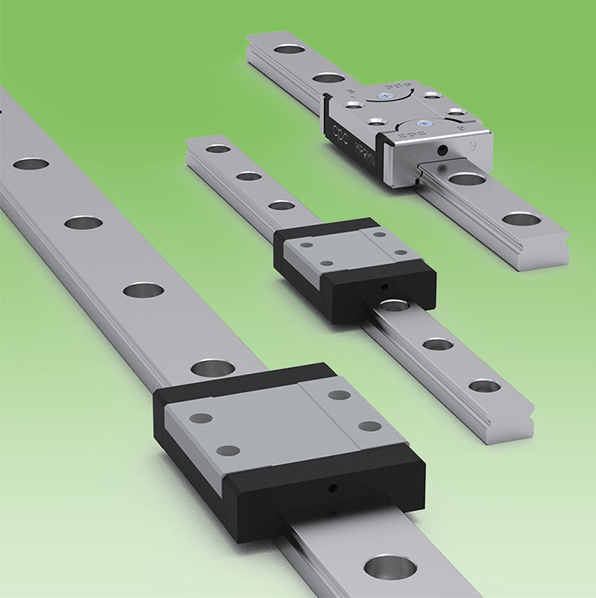

Figure 1: Samples of linear miniature guideways.

The linear guideway is a new type of rolling bearing for relative reciprocating linear motion. It uses the ball rolling between the guide rail and the slider to avoid direct contact between the guide rail surface and the slider surface, and replaces the sliding friction with rolling friction. This can not only improve the movement speed of the slider and ensure the movement accuracy of the slider, but also prolong the service life of the linear guideway.

The working principle of the linear guideway can be understood as a kind of rolling guide. The steel ball rolls infinitely between the slider and the guide rail, so that the load platform can easily move linearly with high precision along the guide rail. It reduces the coefficient of friction to one-fifth of the usual traditional sliding guide, and can easily achieve high positioning accuracy. The design of the terminal unit between the slider and the guide rail enables the linear guide rail to bear the loads in all directions such as up, down, left, right, etc. The simplified structure design allows the linear guide rail to move more smoothly and with low noise.

The following will explain how separate components work in the linear guide mechanism.

How do the Components Work?

Figure 2: Components of a linear guideway.

The basic function of the fixed element (guide) of the linear guide system is like a bearing ring. The bracket for installing the steel ball is in the shape of a "V". The brackets wrap around the top and sides of the rails. To support the working parts of the machine tool, a set of linear guides has at least four brackets. For supporting large working parts, the number of brackets can be more than four.

The linear guideways are mainly composed of guide rails, sliders, balls, retainers, end caps, baffles and gaskets. The guide rail is a supporting part and is installed on the working machine; the slider is a moving part and is installed on the guide rail part; the balls are placed between the guide rail and the slider rail; the retainer is installed between the balls to keep them equally spaced.

The end caps are located at both ends of the slider, and play the role of returning balls, removing chips and lubricating; the baffle is divided into upper and lower baffles to fix the balls; the gaskets include end face, side and inner gaskets, which play a role of dustproof.

When working, the slider moves reciprocatingly along the guide rail. Under the maintenance of the retainer, the balls located between the track surface of the guide rail and the track surface of the slider perform continuous cyclic movement in the raceway, thereby realizing the relative movement of the slider and the guide rail.

Related Info

How to Install a Flame Detector?Tips to Prevent False Flame Detector Alarm

Things to Consider before Purchasing a Point-type Infrared Flame Detector

The Constitution of a Linear Guideway

What is Visual Flame Detector?