Figure 1: Measure air pressure in a cylinder.

(Go to Okmarts and pick the Air Cylinder you need)

During use, the cylinder piston bank will deteriorate due to wearing, ablation, gumming, carbon deposition and other reasons. This will influence the sealing of the cylinder and reduce the power and efficiency of the engine. Cylinder pressure detection is to check the sealing quality of piston ring, valve and combustion chamber. If cylinder pressure is too low it will lead to engine power decline, increase in fuel or oil consumption, excessive emissions, difficult starting and other problems. High pressure will cause engine deflagration and make it difficult to start working. Uneven pressure of each cylinder will cause rough operation of the engine. In case of the above faults, the cylinder pressure should be detected correctly. Through the test results, please analyze and diagnose the tightness of engine cylinder and whether the intake and exhaust system is unobstructed and find out the fault to determine which aspect of repair is needed by other detection and analysis.

1. Measurement Steps

1. Start the engine and let it run in place. When the engine coolant temperature reaches about 80 ℃, stop the engine.

2. Clean the fuel injector mounting hole making dust and dirt out.

Figure 2: Clean the engine.

3. Remove the high-pressure oil pipe and the connector of return pipe on the fuel injector, and then remove the fuel injector. Install a 6 MPa pressure gauge in the threaded hole of the fuel injector (hand-held pressure gauge is not allowed). Gaskets should be added at the joint between the pressure gauge connector and the injector seat hole to prevent air leakage.

Figure 3: Remove the high-pressure oil pipe.

4. Drive the engine with the starter, and the reading number of the pressure gauge is your cylinder’s air pressure.

2. Notes

1. The air pressure cannot be measured when the vehicle is cold. Due to the influence of temperature, atmospheric pressure and other factors, the measured pressure has substantive reference value only when the engine reaches the normal working temperature.

2. For diesel engine, the fuel pump fuse or other relay fuse must be removed during the test, otherwise it will lead to misfire and low pressure.

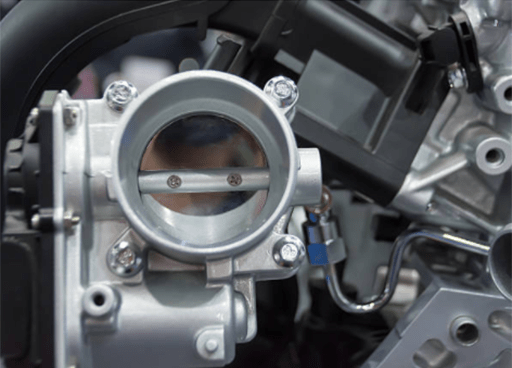

3.Open the choke and throttle valve. Otherwise, the air pressure will be low due to insufficient air intake in the combustion chamber.

Figure 4: Open the choke and throttle valve.

4. Because the cylinder pressure measurement is accidental, it is often inaccurate to measure it only once. Only the test results (average value after 2~3 tests) is effective and reliable.

5.During the test, the running time of the starter should not be too long or too short. Too long running time will consume too much electric energy and damage the starter. Too short running time will make it fail to meet the test standard.

Related Info

Comparison Between Air Cylinder and Electric CylinderWhat is Air Cylinder

Mitsubishi air conditioner e1 e2 e3 e4 e5 e6 and other faults

Ultra3000 servo drive failure repair