What is R22 and R410A?

Figure 1: R410A refrigerant and R22 refrigerant

R22 is the chemical name of difluoromethane, is a member of the Freon family, belongs to the hydrochlorofluorocarbon class. r22 is the more commonly used refrigerant in air conditioning, the international consensus has reached to limit its use, r22 is facing a complete phase-out.

R410A is a kind of refrigerant different from R22, which is a mixture of two quasi azeotropes, mainly composed of hydrogen, fluorine and carbon, with the characteristics of stability, non-toxicity and superior performance. It does not destroy the ozone layer, but produces greenhouse gases.

R22 and R410A 10 major differences

1, R410A belongs to the low toxicity, does not have combustion propagation, R22 is also non-combustible.

2, R410A does not destroy the ozone layer, R22 is deadly destructive to the ozone layer.

3, the total heat transfer characteristics of R410A system than R22, high heat transfer efficiency, heat exchanger can be miniaturized.

4, R410A system cooling capacity is better, R22 is 100%, R410A is 147%.

5, R410A for HFC-32 (R32) and HFC-125 mixed refrigerant.

6, R410A operating pressure than R22 50 ~ 70% higher, about 1.6 times.

7, R410A than R22 vapor density, so R410A vapor flow rate compared to R22 about 30% slower.

8, R410A is more soluble than R22. Residue floating in R410A when it can circulate smoothly in the system.

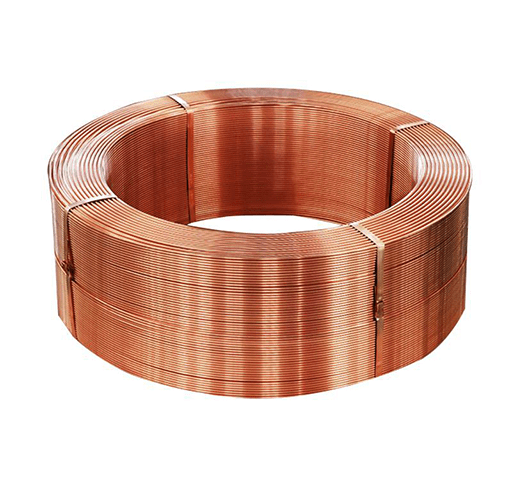

9, R410A requires more copper pipe, while R22 can use ordinary copper pipe.

10, R410A fatal problem: the greenhouse gases that will be produced, and the greenhouse gas effect it produces even partially exceeds that of R22.

Figure 2: the difference between copper pipes

Air conditioning refrigerant r22 and r410 which is better?

R410a is a new type of refrigerant, used to replace R22

From the above difference between refrigerant r22 and r410a and the comparison of their characteristics, we can see that from the environmental protection point of view, R410a is better and will not destroy the ozone layer; from the refrigeration effect, R410a refrigeration effect is also better. But R410A will produce greenhouse gases, the greenhouse effect is strong, environmental protection needs to be improved.

If you want to understand why R410A can replace R22 for a long time, you have to understand the comparison of their respective advantages; if you want to understand the difference between R410A and R22 refrigerant copper pipe you must first understand the two refrigerants.

Figure 3: Top 10 differences between R410A and R22 refrigerants and the difference

Comparison of R22 copper pipe and R410A copper pipe

From the above comparison, we can see that since the pressure generated by R410a refrigerant is 1.6 times higher than that of R22 refrigerant, the requirements for copper pipes are extremely high, which generally require high density, strong pressure resistance, high cleanliness and uniform wall thickness.

Air conditioner copper pipe specification size table

|

Variety |

state |

outer diameter(cm) |

wall thickness(cm) |

main application |

Executive standard |

|

axis roll |

M |

4-22.23 |

0.3-1.5 |

air conditioner refrigerator |

GB17791-99 |

|

Y/M |

6.35-19.05 |

0.5-0.7 |

GB17791-99 |

|

|

|

internal thread |

M |

7-9.52 |

0.32-0.36 |

LTJ902-97 |

|

|

axis roll |

M |

8-13.2 |

0.64-0.7 |

cable duct |

LNB10.02-2002 |

R410A use precautions

Figure 4: Refrigerant copper pipe

1, R410A copper pipe must use high strength pressure resistant special copper pipe. Parts and accessories must also use special. R410a copper tube can be used instead of ordinary R22 copper tube, but never use ordinary R22 copper tube to replace R410a copper tube.

2, R410A new refrigerant split in the installation, must not be confused with the connection tube and refrigerant used in R22 air conditioning.

3, R410A air conditioning installation requirements are high. The action should be rapid, the evacuation should be sufficient, do not drip sweat into the connection pipe, do not mix other insoluble impurities into the system, preferably on a sunny day.

4, maintenance, if you cut the refrigeration system, you must replace the filter drier, and the refrigeration system should not be exposed to the air for more than five minutes.

5, after the repair vacuum, the vacuum pump used should be a special vacuum pump, shall not cause mixed contamination of the refrigerant, and the vacuum time must be guaranteed in more than 25 minutes.

6, R410A refrigerant should be stored in an environment below 30 ° C, if stored in an environment above 30 ° C, must be stored in an environment below 30 ° C for more than 24 hours before use.

Related Info

What is the difference between copper pipes using R410A refrigerant and R22Top 10 Brands of HMI Worldwide

What is Air Cylinder

Top Central Air Conditioner Comparison for Trane vs Daikin vs Mitsubishi vs Carrier

What is the fault code E57 displayed during the use of Mitsubishi Heavy Industries' Haier air conditioner General failure