The nominal pressure of the overflow valve is determined by the operating pressure, the service temperature range of the safety valve is determined by the operating temperature, the constant pressure range of the spring or lever is determined by the calculated constant pressure value of the safety valve, the material and structural type of the overflow valve are determined according to the medium used, and the throat diameter of the overflow valve is calculated according to the discharge capacity. The following are the general rules for overflow valve selection.

Figure 1: Overflow valves.

(1) Hot water boilers generally use an open overflow valve with a wrench.

(2) Steam boilers or steam pipelines generally use non closed fully open overflow valves with wrenches.

(3) Water and other liquid incompressible media generally use closed micro overflow valve or safety relief valve.

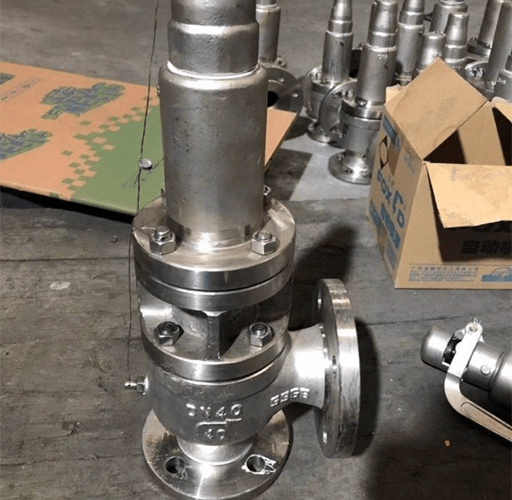

(4) High pressure water supply generally uses closed fully open overflow valves, such as high-pressure water supply heaters, heat exchangers, etc.

(5) Gas and other compressible media generally use closed fully open overflow valves, such as gas tanks, gas pipelines, etc.

Figure 2: Closed fully open overflow valve.

(6) Class E steam boilers generally use weight overflow valves.

(7) Large diameter, large displacement and high pressure systems generally use pulse type overflow valves, such as temperature and pressure reduction devices, utility boilers, etc.

(8) The built-in overflow valve is generally used for the train tank car, automobile tank car, storage tank, etc. transporting liquefied gas.

(9) The hydraulic overflow valve is generally used on the top of the oil tank, which needs to be used in conjunction with the breather valve.

(10) Pilot operated overflow valves are generally used for underground drainage or natural gas pipelines.

(11) The overflow return valve is generally used on the liquid phase return pipeline at the outlet of the tank pump of the liquefied petroleum gas station.

(12) Negative pressure or systems that may generate negative pressure during operation generally use vacuum negative pressure overflow valves.

(13) Bellows overflow valves are generally used for vessels or piping systems with large back pressure fluctuation, toxicity and flammability.

Figure 3: Bellows overflow valve.

1. Other Requirements

The pressure regulation range should be large.

The pressure regulation deviation should be small.

The pressure oscillation should be small.

The action should sensitive.

The overload capacity should be large.

It should work quietly.

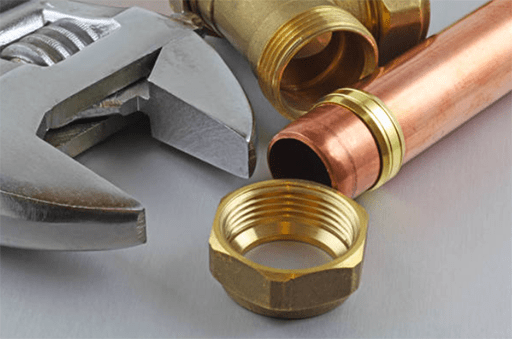

2. Precautions During Installation

1. Clean up the residue: firstly, flush the valve cavity with engine oil. Due to manufacturing reasons, there are iron filings and other objects left in the valve, so as to keep the valve cavity clean.

2. Sealing: before installing the connecting pipe of valve and pipeline, pay attention to adding sealing tape to prevent oil leakage.

3. Valve installation: when installing the valve, connect the interface according to the schematic diagram, keep the connection correct, and minimize the pipeline connection stress.

4. Keep the fluid passing through the valve clean. During the actual installation in the laboratory, the oil circuit is blocked due to impurities in the oil passing through the valve.

5. With the increase of pressure, the adjustment sensitivity of the pressure regulating knob will gradually increase. In the process of pressure regulation, it should be adjusted slowly for many times until the required safety pressure is reached.

Figure 4: Install overflow valves carefully.

Related Info

What is A Overflow ValveTroubleshooting of Overflow Valves

Troubleshooting of Hydraulic Motor

Selection and Use of Hydraulic Motor