Figure 1: Rexroth hydraulic piston pump.

A hydraulic pump is an energy conversion device whose function is to convert the mechanical energy of the prime mover into the pressure energy of the hydraulic oil, thereby providing the hydraulic system with the hydraulic oil of constant pressure and flow. As the power source of the hydraulic system, the normal operation of the hydraulic pump is very important, and its performance directly affects the reliability and stability of the whole system.

However, due to the large working load, high speed and various control methods of the hydraulic pump, it is prone to various failures. Bad oil pump symptoms include:

Hydraulic pump leakage;

Insufficient oil supply of the hydraulic pump or no oil pressure;

Too loud noise of the hydraulic pump when working;

Abnormal heat generation of the hydraulic pump.

The above symptoms may cause a hydraulic pump to fail.

This article mainly analyzes the types and causes of common hydraulic pump failures, and discusses the corresponding solutions, so as to provide help for the efficient use and rapid maintenance of hydraulic pumps.

1. Brief Introduction to Hydraulic Pump

According to different structures, the hydraulic pump can be divided into hydraulic gear pump, hydraulic vane pump and hydraulic piston pump. Although the components of various hydraulic pumps are different, their oil supply principles are the same, and they are all positive displacement pumps.

Its working principle is essentially the change of the sealing volume, that is, on the oil inlet side of the hydraulic pump, the sealing volume gradually increases to form a partial vacuum to suck oil, and on the oil outlet side the sealing volume gradually decreases to push the oil into the hydraulic system.

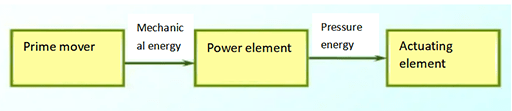

Figure 2: Working process of hydraulic pump.

2. Bad Oil Pump Symptoms, Cause Analysis and Solutions

2.1 Oil Discharge Failure of Hydraulic Pump

The hydraulic pump does not discharge oil or the amount of oil discharge is insufficient, which will affect the operating speed of the actuating element. There are five common reasons for this failure.

1. The oil inlet and outlet of the hydraulic pump are installed reversely, or the rotational direction of the pump is inconsistent with that of the external electric motor.

2. There is insufficient oil in the fuel tank, and the oil level is too low, resulting in discontinuous oil suction.

3. The oil filter in the oil suction pipeline is blocked or the oil filter hole is too small, resulting in a large oil suction resistance.

4. The seal of the hydraulic pump is poor, and the entry of air causes difficulty in oil suction or the connection between the hydraulic pump and other components is loose, resulting in increased leakage.

5. The oil temperature is not appropriate, which makes it difficult for the pump to suck oil. For example: when the oil temperature is too high, the viscosity of the oil is reduced, resulting in serious internal leakage; when the oil temperature is too low, the viscosity of the oil is too large, resulting in the hydraulic pump unable to suck out the oil.

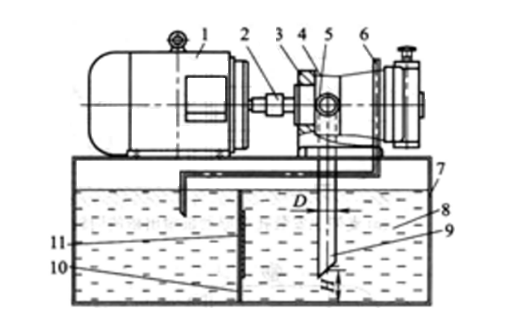

Figure 3: Hydraulic pump station.

In view of the above problems, the following solutions are proposed.

1. Reinstall the hydraulic pump and check whether the rotational direction of the electric motor is consistent with the rotational direction requirements on the nameplate of the hydraulic pump. If it is not consistent, it should be adjusted as required.

2. Add hydraulic oil in time to ensure that the amount of oil in the tank meets the requirements.

3. Clean the oil filter on time or choose an oil filter with lower filtration accuracy under the condition of meeting the working needs.

4. Check the sealing performance of the hydraulic pump, replace the severely worn parts, check the joint surfaces of the hydraulic pump and other components, and ensure that the fasteners are properly connected.

5. Select hydraulic oil with appropriate viscosity or add a device to control oil temperature in the hydraulic circuit.

2.2 Pressure Failure of Hydraulic Pump

Insufficient pressure for oil conveying in the hydraulic pump will cause the actuator to operate weakly. Common reasons are:

1. The pressure gauge is not turned on or the pressure gauge is faulty;

2. The parts of the hydraulic pump itself are seriously worn, resulting in aggravated internal leakage;

3. The hydraulic oil temperature is too high, resulting in low oil viscosity and increased leakage;

4. The setting value of the safety valve is too low or the valve core is stuck at the overflow position of the valve port;

5. The electric motor speed is not enough.

Figure 4: Pressure gauge.

In view of the above problems, the following solutions are proposed:

1. Check and confirm whether the pressure gauge can work normally;

2. Disassemble and repair the hydraulic pump, replace and repair worn parts or send it directly to the factory for overhaul;

3. Select hydraulic oil of suitable viscosity or add a device to control oil temperature in the circuit;

4. Check the safety valve and reset its pressure value;

5. Adjust the electric motor so that its speed is within the working range of the hydraulic pump.

2.3 Abnormal Noise or Vibration of Hydraulic Pump

When the hydraulic pump is working with large noise or severe vibration, the reasons may be as follows:

1. There is air inside the hydraulic pump or the liquid level in the fuel tank is low, causing the pump to inhale air;

2. The pump shaft is not concentric with the external electric motor shaft;

3. There are many impurities in the oil, and the pollution is serious;

4. The internal parts of the hydraulic pump are damaged or severely worn;

5. The diameter of the oil suction pipeline of the hydraulic pump is too small, the pipeline has too many sinuosities and dead ends, or the oil filter is blocked, resulting in insufficient oil suction.

Figure 5: Hydraulic pump on top of oil tank.

1—Electric motor; 2—Coupling; 3—Pump bracket; 4—Hydraulic pump; 5—Oil outlet; 6—Discharge oil pipeline; 7—Oil tank; 8—Oil liquid; 9—Oil suction pipeline; 10—Separation plate; 11 Filter screen

In view of the above problems, the following solutions are proposed:

1. Check the hydraulic pump itself and whether the connection between the pump and other components are normal, prevent inhaling air because of the fasteners loosening, and check the liquid level of the oil tank to avoid the oil level in the oil tank being too low;

2. Adjust the coaxiality of the pump shaft and the motor shaft according to the regulations;

3. Check the cleanliness of the hydraulic oil on time;

4. Disassemble and repair the hydraulic pump, replace the worn parts or send it directly to the factory for overhaul;

5. Select the appropriate oil suction pipe diameter according to the requirements, minimize the pipe sinuosity during installation, and clean the oil filter in time.

2.4 Abnormal Temperature of Hydraulic Pump

The hydraulic pump is abnormally hot or the oil temperature is too high. The common reasons are as follows:

1. The installation clearance of various parts of the hydraulic pump is too small, resulting in serious friction and heat; part of the sliding and matching surface of the hydraulic pump has a large clearance, which increases internal leakage, and the lost pressure and flow are converted into heat energy and generate heat;

2. The pump works for a long time under the working conditions close to or even exceeds the rated pressure or the pressure control valve fails, resulting in the inability to unload and temperature increasing;

3. The return oil is sucked by the hydraulic pump, not through the oil tank cooling yet;

4. Air or moisture is mixed in the oil. When the hydraulic pump sucks or discharges oil, the air and moisture will cause the oil temperature to rise rapidly.

5. The oil is polluted and deteriorated seriously, resulting in a large oil suction resistance of the pump.

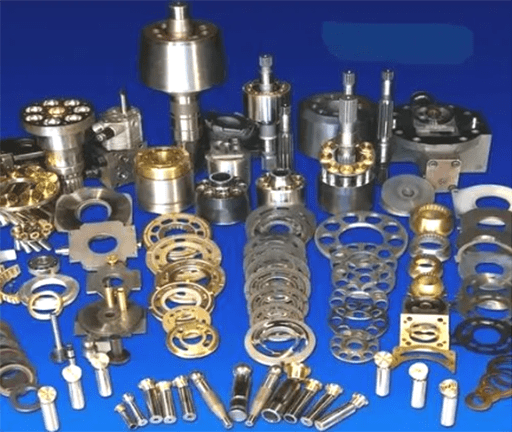

Figure 6: Various hydraulic pump parts.

In view of the above problems, the following solutions are proposed:

1. Measure the assembly gap of each part during assembly to ensure that the matching gap is within the specified range;

2. In each working cycle of the hydraulic pump, the time of the working conditions exceeding the rated pressure should not exceed 6s as much as possible;

3. Separate the oil return port from the pump oil inlet at a distance, and set a baffle in the oil tank;

4. Check the relevant sealing parts and seal them strictly according to the requirements;

5.Replace the hydraulic oil.

2.5 Serious Oil Leakage of Hydraulic Pump

Common causes of oil leakage are:

1. The connection between the inlet and outlet of the hydraulic pump is loose;

2. Serious wear or improper installation of hydraulic pump parts leads to increased matching clearance;

3. The seals of the pipeline connection parts are aged, damaged, deteriorated or the specifications of the seals are wrong, resulting in poor sealing and increased leakage;

4. The oil temperature is too high, and the oil viscosity decreases;

5. The pipeline stress is not eliminated, and the seal is poor.

In view of the above problems, the following solutions are proposed:

1. Tighten pipe joints or screw buckets to ensure tight connection between oil inlet and outlet;

2. Repair the worn parts or directly replace the damaged parts to ensure the normal clearance of the hydraulic pump;

3. Check and use suitable seals to ensure good sealing;

4. Use the oil with high viscosity or add an oil temperature control device to ensure that the oil viscosity meets the requirements;

5. Eliminate pipeline stress and use well-sealed parts.

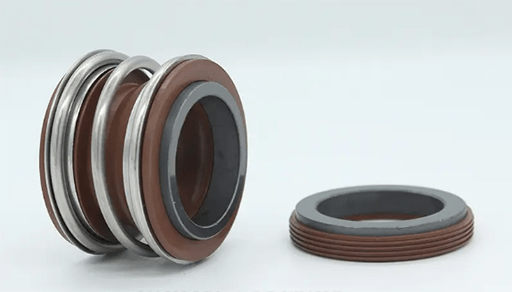

Figure 7: Mechanical seals.

3. Hydraulic Pump Failure Prevention

There are many reasons for the failure of the hydraulic pump, and sometimes one cause may lead to multiple failures. For example, when the parts of the hydraulic pump are seriously worn, the pressure of the hydraulic pump will be low, accompanied by vibration and noise.

Therefore, it is necessary to carry out a comprehensive and systematic preventive inspection on the common faults of the hydraulic pump, analyze the real cause of the failure of the hydraulic pump, so as to ensure the normal operation of the hydraulic pump. When checking the hydraulic pump failure, it is necessary to ensure that the following contents meet the requirements.

1. The parts of the hydraulic pump are installed correctly and the seal is good; the internal parts have no wear or aging phenomenon, and the hydraulic pump can work normally.

2. The hydraulic pump should properly match other components in the system such as fuel tank, safety valve and pipeline, and the connection is reliable.

3. There is no flattening or breakage in the pipeline system; the hose is not kinked, scratched or excessively bent, and if there are a large number of hoses, pipe clamps should be installed separately for fixing; the pipeline and other components are properly fastened, and there is no leaking at the joints.

4. The liquid level in the fuel tank is sufficient and the fuel tank is well sealed to ensure that no air enters during oil filling.

5. Sampling and testing the hydraulic oil to ensure that the cleanliness and viscosity of the oil meet the requirements.

Figure 8: Hydraulic oil.

Therefore, relevant maintenance personnel should do daily maintenance work well to reduce hydraulic pump failures and prolong the service life of the pump. When the hydraulic pump fails, it is necessary to comprehensively analyze the cause of the failure according to the working conditions of the hydraulic pump and the failure phenomena (bad oil pump symptoms) during operation and solve it in time.

In addition, the corresponding inspection and debugging work should be carried out before the hydraulic pump works to ensure that the pump and other components can operate normally, so as to ensure that the entire hydraulic system can work stably and efficiently.

Related Info

How Does a Hydraulic Pump Work?How to Select a Hydraulic Pump

Hydraulic Piston Motor: Types, Working Principle and Pros and Cons (2)

What is Hydraulic Pump? (Function, Types, Application&Selection Method)

Hydraulic Pumps:Types and Pros & Cons