Video: Industrial Control Cabinet Cooling: How to Design the Cooling and Ventilation System?

Figure 1: Industrial cabinet cooling fan.

Control cabinets, such as wind turbine electrical control cabinets, realize system power distribution, monitoring and control of the entire unit. A large number of electrical components are installed in the control cabinet, which will generate heat during operation. Electrical components are relatively temperature-sensitive components. In order to ensure that these components operate within the allowable temperature range, it is necessary to control the environment of the cabinet and design the cooling and ventilation system that meets the environmental requirements of the cabinet inside.

1. Optimal Cabinet Fan Layout

All cabinet ventilation fan systems should include an intake and an exhaust configuration option, which can be cooling fans or ventilation holes.

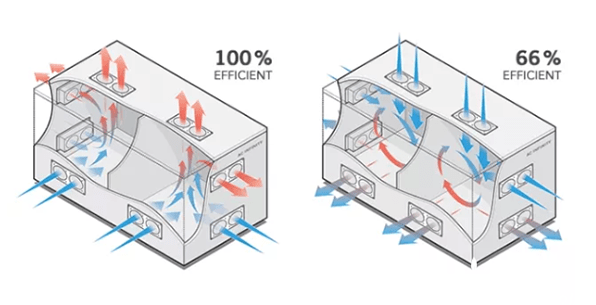

In an ideal layout, a cooling fan needs to be installed near the top of the cabinet to push air out and a fan near the bottom of the cabinet to push air in.

Electrical components in the cabinet will heat up, causing the air to heat up to form natural convection, that is, warm air, which is less dense than cold air, will rise on its own. An efficient cooling fan system helps accelerate natural convection, quickly expelling hot air from the top of the cabinet while pushing cold air in from the bottom.

Figure 2: Layout of control cabinet cooling system.

If a cabinet fan system contains only one cooling fan, it should be configured to exhaust hot air from the top of the cabinet. There must be ventilation holes elsewhere on the cabinet, preferably towards the bottom, as air intakes.

Using cooling fans to remove air will result in negative pressure or a reduction in pressure within the cabinet. Because air naturally flows from high-pressure areas to low-pressure areas, outside air will flow into the cabinet from the ventilation holes.

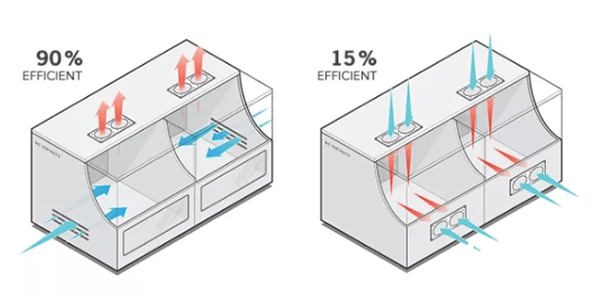

Poorly designed systems that include one or more cooling fans for air intake but no fans or ventilation holes as exhaust outlets are the least efficient at dissipating heat.

Figure 3: Layout of control cabinet cooling system.

The figures above show the huge difference in working efficiency under different fan and ventilation configurations. Therefore, when designing specific cabinet cooling and ventilation, the optimally configured system can be designed based on the actual cabinet's spatial location, protection level, cost factors, etc.

2. Calculation of Air Volume Required for Cabinet Cooling

The calculation of the air volume required for cabinet cooling requires consideration of the influence of various factors. The main factors to consider are the temperature inside the cabinet, the temperature outside the cabinet, the natural heat dissipation capacity of the cabinet wall itself, the heat generated inside the cabinet, altitude and other factors. Only by fully considering these factors and determining accurate parameters can the best matching fan air volume be calculated.

The cabinet itself has a certain heat dissipation capacity through the cabinet wall. When its own heat dissipation capacity cannot meet the temperature requirements of the components in the cabinet, forced cooling must be used to ensure that the internal temperature of the control cabinet is within the allowable temperature range. Common forced cooling solutions include cooling fans, industrial air conditioners, and heat exchangers. In most areas, fans can meet the cooling needs

Below we calculate the cooling air volume required for the cabinet and introduce the air volume calculation equation used.

First calculate the heat dissipation power of the control cabinet itself:

Figure 4: Heat transfer formula.

Required forced cooling:

Q=Q1-Q2

Q: Required heat dissipation capacity

Q1: Total heat generated in the control cabinet (W)

Q2: The heat dissipation capacity of the control cabinet itself

When Q is 0 or a negative value, it means that the heat generated in the cabinet can be solved by the cabinet's own heat dissipation capacity, and there is no need to configure additional forced cooling equipment. When Q is a positive value, it means that the cabinet's own heat dissipation capacity is insufficient, and a forced cooling solution needs to be configured.

Based on the above formula and various parameters obtained from actual operation, we can accurately calculate the required air volume.

Figure 5: A cooling fan installed in the cabinet.

3. Cabinet Fan Selection and Installation

After calculating the accurate air volume demand, we can determine the final quantity and installation location of cooling fans based on the structural size of the cabinet, the specifications of the actual selected fans, the cost, the cabinet protection level requirements, etc.

The selection of the cooling fan can be based on the air volume and wind pressure, and the fan model can be determined by referring to the fan's characteristic curve, so that the fan works at the highest efficiency point, which not only increases the fan life but also improves the ventilation efficiency of the equipment.

Figure 6: Fan characteristic curve.

3.1 Precautions

The advantage of the fan cooling method is low cost, but the disadvantage is that it is easy to bring dust, corrosive gases and other harmful substances outside into the cabinet, which may cause damage to the components inside the cabinet. Therefore, this cooling method has certain requirements for the application site, and the ventilation channels of the cabinet need to be improved, such as adding filters.