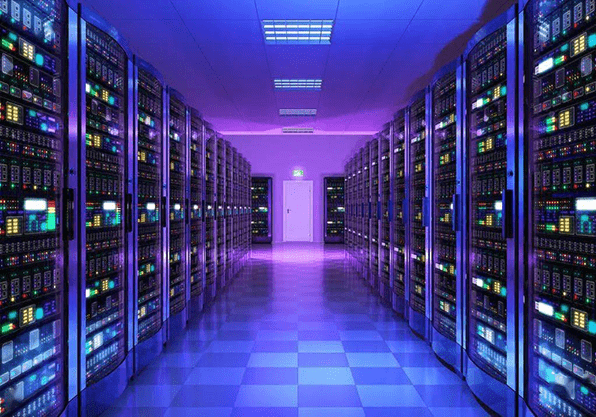

Figure 1: Data center.

At present, data centers mainly use two types of refrigerants. One is R410a, which is mainly used in small or medium-sized data centers with air conditioning cooling capacity of 300-400 KW. The other is R134a, which is mainly used in large automobile air conditioning systems and water chiller units.

1. R-410a Refrigerant Basic Information

Alias R410a, product names include , Freon 410a, SUVA 9100, Genetron AZ-20, Genetron 410a, etc.

The system working pressure is 0.7-0.8MPa during cooling and 2.88-3.2MPa during heating.

Because R-410a is an HFC-type near-azeotropic environmentally friendly refrigerant, it is currently the mainstream

medium- and high-temperature environmentally friendly refrigerant recognized and recommended by most countries in

the world.

It complies with the standards of the U.S. environmental organizations EPA, SNAP and UL, and complies with the

safety classification of A1 of the American Society of Heating Refrigerating and Air-conditioning Engineer (ASHRAE).

Figure 2: R-410a refrigerant.

1.1 R410a Main Features

(1) No damage to the ozone layer. Its molecular formula does not contain chlorine, so its ozone depletion potential

(ODP) is 0.

(2) Very low toxicity. The allowable concentration is the same as R22, 1000ppm.

(3) Non-flammable. The flammability in air is 0.

(4) High chemical and thermal stability.

(5) Water solubility is almost the same as R22.

(6) It is a mixed refrigerant, consisting of two refrigerants

(7) Undissolved with mineral oil or alkylbenzene oil. (Be able to dissolve with POE [ester lubricant] and PVE [ether

lubricant]).

1.2 R410a Main Uses

(1) R410a is a widely used medium and high temperature refrigerant today. It is mainly used in household air

conditioners, small and medium-sized commercial air conditioners (small and medium-sized unit air conditioners,

household central air conditioners, multi-split units), portable air conditioners, dehumidifiers, and refrigerated

dryers. , marine refrigeration equipment, industrial refrigeration and other refrigeration equipment.

(2) R410a refrigerant is the best and final choice to replace Freon R22 in newly installed refrigeration equipment

(usually air conditioning systems). For refrigeration equipment initially using R22, R410a can be used to directly

replace R22 during maintenance or replacement.

Figure 3: Outdoor units of air conditioners.

2. R134a Refrigerant Basic Information

Alias R134a, HFC134a, HFC-134a, product names include Freon 134a, Genetron 134a, KLEA 134a, etc., chemical name is

1,1,1,2 --Tetrafluoroethane, and chemical formula CH2FCF3.

Because R134a is an HFC substance, it does not damage the ozone layer at all. It is an environmentally friendly

refrigerant recognized and recommended by most countries in the world, and it is also the current mainstream

environmentally friendly refrigerant.

The system working pressure is 0.3~0.4MPa during cooling and 1.2~1.4MPa during heating.

Figure 4: R134a refrigerant.

2.1 R134a Main Features

(1) R134a has a global warming potential (GWP) of 1300 and is a greenhouse gas.

(2) The ozone depletion potential (ODP) of R134a is 0, which is the reason why R134a becomes an environmentally

friendly refrigerant.

(3) The specific volume of R134a is 1.47 times that of R22, and the latent heat of evaporation is small. Therefore,

the refrigeration capacity of the R134a unit is only 60% of that of the R22 unit. Calculated based on unit cooling

capacity price, the price of R22 unit is about 60% of that of R134a unit.

(4) The thermal conductivity of R134a is 10% lower than that of R22, so the heat exchange area of the R134a unit

heat exchanger needs to be larger.

(5) R134a has strong water absorption, which is 20 times that of R22. Therefore, the requirements for the dryer in

the unit system are higher to avoid ice blockage.

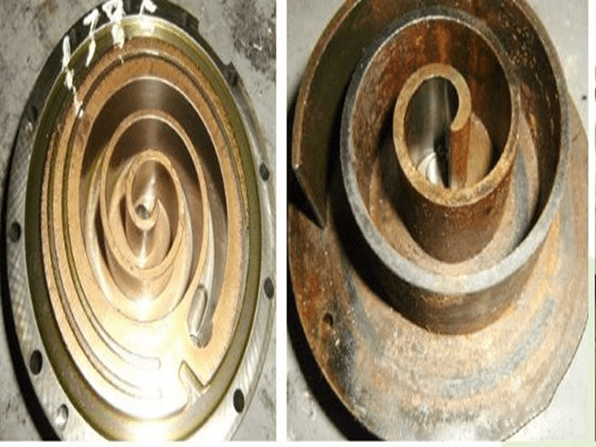

(6) R134a has a stronger swelling effect on rubber substances than R22, and the refrigerant leakage rate is higher

in actual operation. In addition, it is highly corrosive to copper, and "copper plating" will occur during use, so

additives must be added to the system.

Figure 5: Copper plating.

(7) The R134a system requires a dedicated compressor and dedicated lubricating oil. Due to its

high water absorption, high foaming and high diffusivity, the lubricating oil is inferior to the mineral oil used in

the R22 system on the stability of system performance.

(8) The price of R134a and other HFCs refrigerants and its special lubricating oil is higher than that of R22, and

the operation and maintenance costs of the equipment are higher.

2.2 R134a Main Uses

(1) R134a, as the most widely used medium and low temperature environmentally friendly refrigerant, is a substitute

for R12.

(2) Mainly used in refrigeration equipment such as refrigerators, freezers, water dispensers, automobile air

conditioners, central air conditioners, dehumidifiers, cold storages, commercial refrigeration, ice water machines,

ice cream machines, refrigeration condensing units, etc., and can also be used in aerosol propellants, medical

aerosols, insecticide propellants, polymer (plastic) physical foaming agents, and magnesium alloy protective gases,

etc.

3. R410a VS R134a on Different Aspects

Table 1: R410a VS R134a refrigerant.

3.1 Thermal Performance Comparison: R410A>R134A

The standard boiling point of R410A is -51.6°C, while that of R134A is only -26.2°C. Therefore, the biggest

advantage of R410A over R134A is its outstanding heating capability in low-temperature environments.

R410A also has good heat transfer capabilities under -30°C working conditions. In addition, the latent heat of

vaporization of R410A is nearly 25% higher than that of R134A, so the cooling capacity and heating capacity per unit

mass of R410A are much higher than that of R134A.

3.2 Comparison of Environmental Protection Characteristics: R410A < R134A

The ODP value (ozone depletion potential) of both is 0, but the GWP value (global warming potential) of R134a refrigerant is much lower than that of R410a, which means that R134a is significantly better than R410a refrigerant in terms of CO2 emission reduction.

3.3 Cycle Performance Comparison: R410A<R134A

The cooling capacity per unit volume of R410a is about 1.2 times higher than that of R134a, and the power consumption increases by 1.5%. Experimental results also show that the refrigeration system using R134a has a slightly higher energy efficiency than R410a.

3.4 Manufacturing Cost Comparison: R410A<R134A

R410a refrigerant has higher capacity and pressure than R134a refrigerant. Refrigeration systems using

R410a refrigerant can not only use smaller displacement compressors, but also smaller diameter pipes and

valves, so the cost of using R410a refrigerant system is lower.

In order to achieve the same cooling capacity, R134a requires a higher gas transmission capacity. If the

same type of compressor is used, a compressor with a larger displacement is needed, as well as larger

evaporator, condenser and pipeline, etc. This will lead to an increase in the manufacturing cost of the

refrigeration system and it is not recommended to use this refrigerant in micro and small data centers.

From the above comparison, the advantage of R410A is that it has good low-temperature heating

performance and low manufacturing cost; the advantage of R134A is that it has better environmental

performance and a slightly higher energy efficiency ratio.

4. Summary

It can be seen that compared with R134a, R410a has certain advantages and is currently mainly used on

small units. R134a is now mainly used in heat pump units and household refrigerators, and is also used

in centrifugal chillers. However, it is not recommended to use R134a when the evaporation temperature is

lower than -15°C.

However, both their GWP values are relatively high. As environmental protection pressure increases day

by day, R410a and R134a will also be gradually replaced. By then, new mainstream refrigerants will

appear in data centers. These changes will put forward new requirements for compressors, UPS, and other

equipment.