The solenoid valve is one of the common valves in industrial control systems. It can control the opening and closing of the valve through electromagnetic force, thereby achieving control of the gas and liquid lines. Due to its simple structure, sensitive response, and reliable action, solenoid valves have been widely used in the field of industrial automation.

According to different classification standards, solenoid valves can be divided into many types.

1. Common Types of Solenoid Valves

1.1 Classified by Working Principle

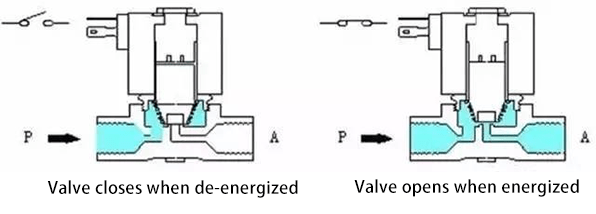

1. Direct-acting solenoid valve (direct operated solenoid valve): It can work normally under vacuum, negative pressure and zero pressure, but the diameter generally does not exceed 25mm.

2. Semi-direct acting solenoid valve (semi-direct operated solenoid valve): It can also operate under zero pressure difference, vacuum or high pressure, but the power is large and it must be installed horizontally.

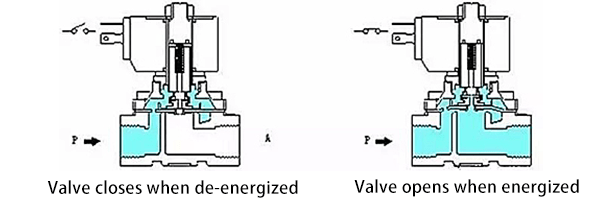

3. Indirect acting solenoid valve (pilot-operated solenoid valve): The upper limit of the fluid pressure range is higher, and it can be installed arbitrarily (customization required) but it must meet the fluid pressure difference conditions.

1.2 Classified by Material

1. Stainless steel solenoid valve: It is the most common solenoid valve product and is the most popular among users because of its good quality and stable operation.

*This type of solenoid valve is widely used in production and scientific research departments such as textiles, printing, chemicals, plastics, rubber, pharmaceuticals, food, building materials, machinery, electrical appliances, and surface treatment, as well as in people's daily life such as bathrooms, canteens, and air conditioners.

2. Brass solenoid valve: Some users with low requirements for the solenoid valve will choose the brass type. The price of such solenoid valves is relatively low and they are suitable for ordinary working environments.

* This type of solenoid valve is generally suitable for liquid, water, gas, hot water, oil, gas and other media.

3. Plastic solenoid valve: Used in some special workplaces and with special media, such as working environments with acidic and alkaline media, brass and stainless steel solenoid valves are easily corroded, but plastic solenoid valves made of special materials (PVC, CPVC, UPVC, ABS or PTFE, etc.) are particularly excellent in corrosion resistance.

* This type of solenoid valve is suitable for drinking water, various types of untreated sewage, rainwater, seawater, various acid and alkali salt solutions, organic solvents, etc.

1.3 Classified by Application Areas

1. Liquid solenoid valve: It is mainly used to control the opening and closing of liquid media, such as water, oil, acid, alkali, etc. It has the characteristics of good sealing, corrosion resistance, and high pressure resistance, widely used in water treatment, petrochemical, food processing and other industries.

2. Gas solenoid valve: It is mainly used to control the opening and closing of gas media, such as air, nitrogen, oxygen, etc. It has the advantages of fast response, precise control, and anti-explosion, widely used in industrial automation, aerospace, gas equipment and other fields.

3. Steam solenoid valve: It is used to control the opening and closing of steam medium. With the characteristics of high temperature resistance, high pressure resistance and corrosion resistance, steam solenoid valves are widely used in heating, printing and dyeing, pharmaceutical and other industries.

1.4 Classified by Medium Temperature

1. Normal temperature solenoid valve: It is suitable for medium temperature of -5℃~100℃, mainly used to control medium pipelines for air, water, steam and so on.

2. Medium temperature solenoid valve: It is suitable for medium temperature of 100℃~250℃, mainly used to control high temperature steam pipelines.

3. High temperature solenoid valve: It is suitable for medium temperature above 250℃, mainly used to control high temperature gas pipelines.

2. Summary of Common Solenoid Valve Types

● According to the different internal structures of solenoid valves, they can be divided into: pilot type, direct-acting type, compound type, recoil type, self-holding type (double coil), pulse type, bistable type, bi-directional type, etc.

● According to the different materials used in the solenoid valve, they can be divided into: cast iron body (gray cast iron, ductile iron), copper body (cast copper, forged copper), cast steel body, all stainless steel body (304, 316), and non-metallic material ( ABS, PTFE).

● According to the medium in the controlled pipeline and the working conditions, they can be divided into: liquid solenoid valve, gas solenoid valve, steam solenoid valve, oil solenoid valve, special solenoid valve for fire protection, refrigeration solenoid valve, anti-corrosion solenoid valve, high temperature solenoid valve, high pressure solenoid valve, zero-pressure differential solenoid valve, ultra-low temperature solenoid valve (cryogenic solenoid valve), vacuum solenoid valve, etc.

● According to different medium temperatures, they can be divided into: normal temperature type, medium temperature type, high temperature type, ultra-high temperature type, low temperature type and ultra-low temperature type.

● According to the medium pressure in the pipeline, they can be divided into: vacuum type (-0.1~0Mpa), low pressure type (0~0.8Mpa), medium pressure type (1.0~2.5Mpa), high pressure type (4.0~6.4Mpa), and ultra high pressure type (10~21Mpa)

● According to different working voltages, they are divided into: AC voltage type( AC220V 380V 110V 24V), and DC voltage type (DC24V 12V 6V, 220V).

● According to the protection levels of solenoid valves, they can be divided into: explosion-proof type, waterproof type, outdoor type, etc.

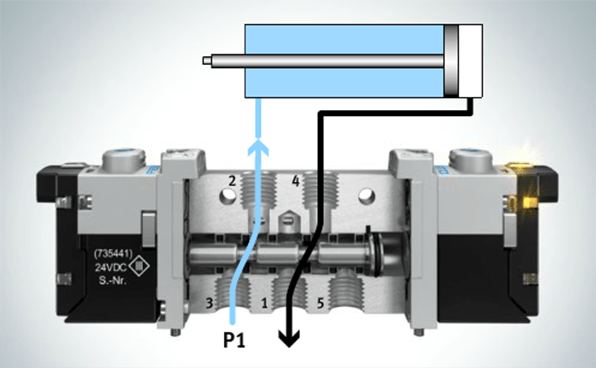

● According to the number of ports and position states, they are divided into 2-position 2-way, 2-position 3-way, 2-position 4-way, 2-position 5-way, etc.

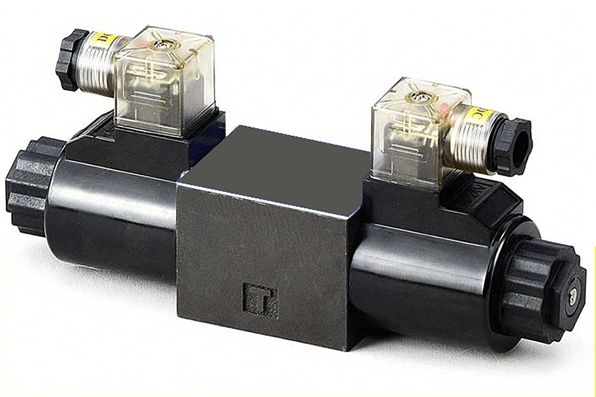

● Solenoid valves are divided into single solenoid and double solenoid according to the number of solenoid coils. Generally 2-position 2-way, and 2-position 3-way valves are single coil type, while 2-position 4-way, and 2-position 5-way valves can be single coil type or double coil type.

To sum up, there are many types of solenoid valves, and each type of them has its own unique working principle, structural characteristics and application fields. In practical applications, we need to select the appropriate solenoid valve type based on specific control requirements, working conditions and medium characteristics. At the same time, we also need to pay attention to the quality, reliability, life and other performance parameters of the solenoid valve to ensure its stability and reliability in actual operation.