There are four main components in the central air conditioning system, namely: compressor, condenser, throttling device, and evaporator. Evaporators and condensers are collectively referred to as heat exchangers, and the difference in names is defined according to the different processes of the air conditioner in the refrigeration and heating cycles.

Figure 1: Working principle diagram of central air conditioning cooling process.

Figure 2: Working principle diagram of central air conditioning heating process.

1. Throttling Device

Its function is to throttle the saturated liquid (or subcooled liquid) under the condensation pressure and reduce it to the evaporation pressure and temperature. At the same time, it adjusts the flow of refrigerant entering the evaporator according to the load changes.

To put it bluntly, it is a device to improve heat absorption efficiency.

If the amount of liquid supplied to the evaporator by the throttling device is too large compared to the load of the evaporator, part of the refrigerant liquid and gas will enter the compressor together, causing wet compression and liquid slugging accidents.

On the contrary, if the liquid supply is too small compared with the heat load of the evaporator, part of the heat exchange area of the evaporator will not be able to fully function, and even cause the evaporation pressure to decrease. Moreover, the cooling capacity of the system is reduced, the refrigeration coefficient is reduced, and the exhaust temperature of the compressor is increased, which affects the normal lubrication of the compressor.

1.1 3 Common Throttling Devices

Thermal expansion valve, capillary tube, and electronic expansion valve are three important throttling devices.

1. Thermal Expansion Valve

Figure 3: Thermal expansion valve.

Thermal expansion valves are commonly used in Freon refrigeration systems. Through the action of the temperature sensing mechanism, they will automatically vary with the temperature change of the refrigerant at the evaporator outlet to achieve the purpose of adjusting the liquid refrigerant supply.

The superheat of most thermal expansion valves will be set at 5-6°C before leaving the factory, and the structure of the valve ensures that when the superheat increases by 2°C, the valve will be in the fully open position. When the superheat is about 2°C, the expansion valve will be closed. The adjustment spring for controlling the degree of superheat has an adjustment range of 3-6°C.

Generally speaking, the higher the superheat setting of the thermal expansion valve, the lower the heat absorption capacity of the evaporator, which means that the surface of the evaporator cannot be fully utilized.

However, if the degree of superheat is too low, the refrigerant liquid may be brought into the compressor, causing the unfavorable phenomenon of liquid slugging. Therefore, the adjustment of superheat should be appropriate, which can not only ensure that enough refrigerant enters the evaporator, but also prevent liquid refrigerant from entering the compressor.

The thermal expansion valve is mainly composed of a valve body, a temperature sensing bulb and a capillary tube. There are two types of thermal expansion valves, internally equalized and externally equalized.

2. Capillary Tube

Figure 4: Capillary tube.

The capillary tube is the simplest throttling device and is a copper tube with a specified length and a very thin diameter. Its inner diameter is generally 0.5 to 2mm.

Features of the capillary tube as throttling device:

(1) The capillary tube is made of drawn copper tube, which is easy to manufacture and low in price.

(2) There are no moving parts, and it is not easy to cause failure and leakage.

(3) It has the characteristics of self-compensation. After the refrigeration compressor stops running, the pressure of the high-pressure side and low-pressure side in the refrigeration system can be quickly balanced.

3. Electronic Expansion Valve

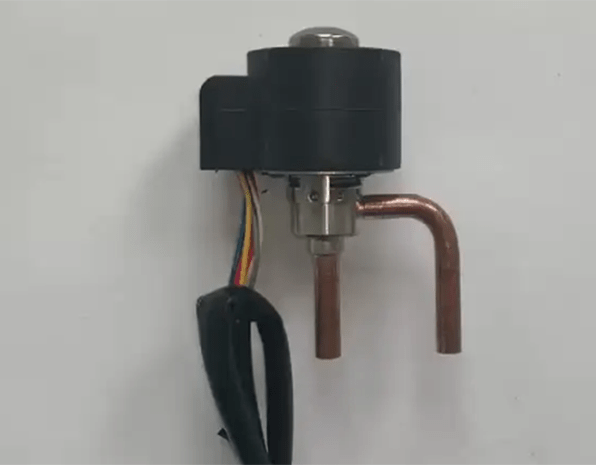

Figure 5: Electronic expansion valve.

Advantages:

(1) The flow adjustment range is large;

(2) High control precision;

(3) Suitable for intelligent control;

(4) It can be applied to the rapid change of high-efficiency refrigerant flow.

The opening degree of the electronic expansion valve can be adapted to the speed of the compressor, so that the amount of refrigerant conveyed by the compressor matches the amount of liquid supplied by the valve to maximize the capacity of the evaporator, and realize the best control of the air-conditioning and refrigeration system.

The use of electronic expansion valves can improve the energy efficiency of the inverter compressor, realize rapid temperature adjustment, and increase the seasonal energy efficiency ratio of the system. For high-power inverter air conditioners, electronic expansion valves must be used as throttling components.

The electronic expansion valve consists of three parts: detection, control and execution. According to the driving mode, it can be divided into electromagnetic expansion valve and electric expansion valve. The electric type is divided into direct-acting type and deceleration type.

2. Evaporator (Endothermic)

The function of the air conditioner evaporator is to use the liquid low-temperature refrigerant to evaporate easily at low temperature and convert into steam and absorb the heat, so as to achieve the purpose of refrigeration.

Figure 6: Central air conditioning evaporators.

2.1 Types of Evaporator

According to the type of medium to be cooled, evaporators are usually divided into two categories: one is the evaporator for cooling air, such as the evaporation tubes used in household window air conditioners, wall-mounted (split) air conditioners, cold storage rooms and refrigerated vehicles and ships, etc.

The other is the evaporator for cooling liquid, such as the evaporator in the chiller of central air-conditioning in hotels, restaurants, department stores, theaters, factory workshops, etc., the evaporator in the cold drink machine, and the evaporator for cooling brine in the ice making pool, etc.

3. Condenser (Exothermic)

The function of the condenser is to cool the high-temperature and high-pressure superheated steam discharged from the compressor into a liquid or a gas-liquid mixture, and release heat to the outside in the process.

The heat released by the condenser is carried away by the cooling medium (water or air). Condensers can be divided into two types according to different cooling media:

1. Air-cooled condenser: The heat of the refrigerant is transferred to the copper tube, then to the aluminum foil, and dissipated in the air.

2. Water-cooled condenser: The heat of the refrigerant is first transferred to the copper tube, and then transferred to the water for discharge.

For fluorine system air conditioners, air-cooled condensers are generally selected.

Figure 7: Air-cooled central air conditioner.

4. Compressor

The working principles and advantages and disadvantages of the five central air-conditioning compressors will be introduced in detail in the next article.

Related Info

Diagnosis and Troubleshooting of Refrigeration Compressor Failure13 Reasons Why Your Samsung Refrigerator Not Cooling (The Latest Version)

How Refrigerator Compressor Works (Structure Diagram, Working Principle Diagram)

How to Change Air Compressor Oil (5 Steps)

4 Types of Safety Protection for Refrigeration Compressors (9 Common Protection Devices for Refrigeration Compressors)