1. Overview of HMI Tablet

Due to the shortage of energy supply, and increasingly significant environmental problems, new energy resources have been gradually known to people. Wind energy is a type of renewable clean energy.

The development of wind power generation is of practical significance to the adjustment of energy structure, energy conservation and emission reduction, reducing environmental pollution and improving the ecological environment.

A human machine interface (HMI) tablet can offer a three-tier monitoring system including wind turbine monitoring, single wind farm monitoring and wind farm cluster monitoring to empower the work of wind power generation.

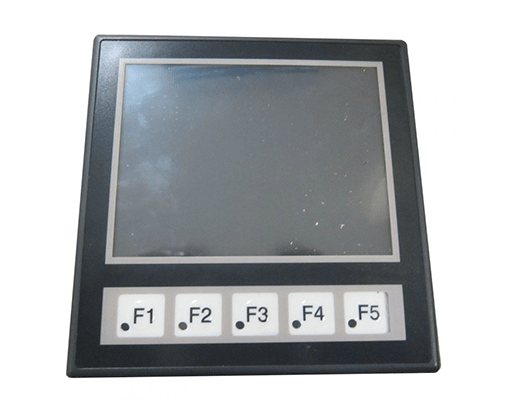

Figure 1: Fuji HMI GD-80E01MJ-B

2. Functions of HMI Tablet

The electric monitoring system is divided into three levels.

Data Acquisition on Site

The control system collects all kinds of equipment signals through PLC or PAC so as to detect and control the operation of some equipment.

Industrial PC and Industrial Switch

Through the industrial PC, the status of the extension equipment can be monitored on site. Plus the industrial PC can issue the command to control the status of the fan blade. It’s the data exchange of the industrial switch and electric field server that can ensure the normal and stable operation of the system by the use of highly reliable industrial equipment. - 25 ℃ - 60 ℃ is the ambient temperature of HMI tablet which has strong adaptability to the actual situation.

It can store the data in the industrial electronic disk, and even if the network is interrupted, there is always the collected data. The whole machine adopts low-power sealed embedded platform, improving the device’s stability and reliability in harsh environment greatly. The data of the fan can be viewed and changed through the HMI touch screen on site.

Figure 2: KOYO HMI EA1-T4CL

Display Size: 4in

Viewable Size: 4.1in

Display Type: Color TFT LCD

Widescreen: No

Display Maximum Colors: 32K colors

Display Resolution (W x H): 320 x 240 pixel

Display Video Standard: QVGA

Display Orientation: Landscape/portrait

Backlight Type: LED

Power Requirement: 24 VDC

Housing Rating: EMA 4/4X

Environmental Requirements: Indoor use only

IP Rating: IP65

Serial Ports: (1) RS-232/422/485

USB Ports: (1) 2.0 Type B

Software Required: EA-MG-PGMSW programming software v3.0 or later

Includes: Mounting hardware, gasket and cutout template"

Wind Farm Server

The monitoring center is applied with the wind farm server to monitor all the fans in the wind farm at the same time, and display the status and parameters of each fan in real time. The wind farm server controls the running speed of the fan according to the specific air volume, and monitor and store the running data by managing the fan comprehensively.

3. Requirements for HMI Tablet

Most of the wind farms are set in places such as sparsely populated land, and places with large temperature difference between day and night, and severe sandstorm. And the ambient temperature of HMI tablet is - 25 ℃ - 60 ℃. Wind power group generally governs many wind power companies and farms, and its management mode is multi-level management system and group operation.

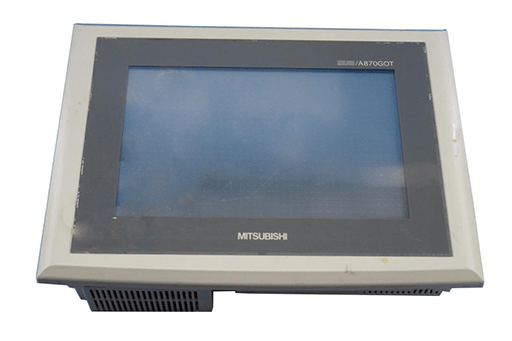

Figure 3: Mitsubishi HMI A8GT-70GOT-EW

Motor control system is usually in a bad electromagnetic environment, so monitor products are required with strong anti electromagnetic interference ability and stability. In order to ensure the reliability of communication, the HMI tablet system is set with redundant network port, serial port, power supply system. Besides, the system should be convenient to maintain and operate.

For ensuring the security of remote monitoring data, the HMI tablet system is capable of realizing remote management and intelligent control. In view of the characteristics of wind resources, it is very important for the system to effectively monitor the wind turbine for the purpose to ensure the safe, reliable and economic operation of the wind farm.

4. Data Collected by HMI Tablet

Main information of fans: wind speed, power, power generation, generation time, temperature, humidity.

Impeller / Variable pitch system: blade angle, temperature of variable - pitch motor, angle of impeller to air.

Converter / Cooling system: temperature, humidity.

Motor / Grid system: motor speed, acceleration, and current, voltage, frequency, power of the grid.

Yaw / Hydraulic system: yaw position, wind, wind speed, atmospheric pressure.

Operation environment monitoring: environmental temperature and humidity, temperature and humidity of engine compartment, temperature and humidity of tower base.

Related Info

Application of HMI in PLC Based Industrial Control SystemDo You Really Understand Human Machine Interface (HMI) - HMI Q&A

PLC (Programmable Logic Controllers) and HMI (Human-Machine Interface) for Intelligent Factory

A Quick Look at HMI Touch Screen in Industrial Scenes