Figure 1: Magnet pump.

1. What it is

Magnet Pumps are seal-less pumps that use the technology of a drive magnet and inner magnet connected to an impeller to move fluid through the pump. The drive magnet and inner magnet are separated by a rear casing or housing, creating a seal-less containment. A Mag Drive Pump will prevent the leakage of fluid and even more importantly save you from the loss of potentially dangerous and costly liquids. With environmental concerns and EPA requirements more stringent than ever, seal-less pumps allow for zero fugitive emissions, allowing them to meet the necessary compliances. Due to their simplicity, mag drive pumps save maintenance time replacing seals and dealing with hazardous leaks. With only two moving parts, there is little chance for failure. Mag drive pumps are the answer for reliability and zero emissions.

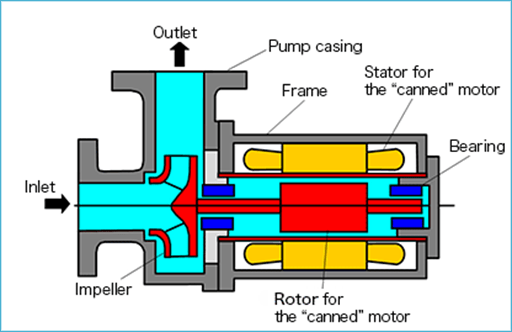

Figure 2: Structure of a magnet pump.

2. How it Works

A magnet pump uses a balanced magnetic field to create the rotation of the fluid impeller. Unlike a traditional centrifugal pump which has a direct drive connection between impeller and motor, a mag-drive pump eliminates the direct drive mechanism and replaces it with a magnetic field. An outer magnetic bell housing is mounted on the end of the pump shaft. This outer bell is aligned on the outside of the rear casing. The pump impeller is connected to a smaller magnet assembly and rides on an internal shaft and bushing assembly. (The liquid end parts are all isolated within the fluid head of the pump without the need for a mechanical seal.) The smaller magnet assembly is mounted within the center of the magnetic field of the outer bell housing. Although these two magnet assemblies are separated by a fluid barrier, the magnetic fields are aligned. When the pump motor is started the outer bell housing begins to rotate. As the outer bell rotates, the rotating magnetic field effects the inner impeller magnet. As the two magnets begin to turn together, the impeller begins turning and displacing fluid.

Figure 3: Working principle of magnet pumps.

3. Magnet Pump or Canned Motor Pump

In a canned motor pump, the motor’s rotor winding is encapsulated in a ‘can’ and it, and the entire drive shaft up to the impeller is immersed in the pumped fluid.

Canned motor pumps tend to be smaller, have fewer bearings and can be more efficient. They also offer secondary containment as standard: if the ‘can’ is ruptured then the pumped medium is contained within the stator housing. This can be a particular advantage if the pumped medium is so dangerous or expensive that secondary containment is essential. Magnetic pump manufacturers offer secondary containment on some designs but this is usually an additional cost.

Figure 4: Canned motor pumps.

The main disadvantage of canned motor pumps is that a motor failure requires replacement of the whole unit. A magnet pump can be repaired or upgraded because the motor is not an integral part of the pump. Both canned and magnetic drive pump designs have versions available to handle slurries, liquids at both high and low temperature, and volatile fluids.

Often, the choice of pump depends only on site standards or preferences.

Related Info

What is Check Valve?Types of Check Valve

How to Install a Sump Pump Check Valve: 5 Steps

How To Repair a Pool Spring Flapper Check Valve?