1. Types of Vacuum Pump

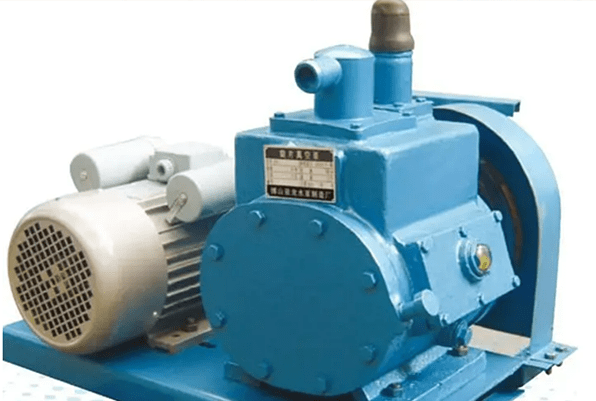

Figure 1: The appearance and model of rotary-vane vacuum pump.

1.1 According to the working principle

According to the working principle of vacuum pump, there are two types of vacuum pumps.

Extraction vacuum pump: Vacuum pump sucks air in the system, and discharges the air molecules out of the system.

Capture vacuum pump: Vacuum pump traps air molecules in the system, and makes them directly absorb the working wall of pump without discharging out of system.

1.2 According to structure

According to structure of vacuum pump, there are three types of vacuum pumps.

Mechanical vacuum pump: This type of vacuum is similar to compressor and it is a volumetric type with reciprocating and rotary structures. Besides, together with powered turbo molecular pump, they also belong to extraction vacuum pump.

Jet vacuum pump: There are two types including jet pump and diffusion pump. Booster pump that integrates jet pump with diffusion pump also belongs to extraction vacuum pump.

Suction vacuum pump: This type of pump uses physical or chemical measures to absorb air molecules on the wall of pump, which belongs to trapping vacuum pump.

Figure 2: The model of turbine molecule backing pump.

1.3 According to working role

According to working role of vacuum pump in the system, there are four types of vacuum pumps.

Main air extraction pump: It plays a main role of working pump to achieve required pressure.

Pre-extraction pump: When the main air extraction pump cannot directly start pumping in the atmosphere, the pre-extraction pump needs to be pumped to a certain pressure before the main air extraction pump can start to work.

Backing pump: When main air extraction pump cannot directly discharge the extracted air into atmosphere, it is necessary to connect backing pump in series.

Holding pump: When main air extraction pump completes the required pressure and stops working, the pressure may rise due to system leakage or surface evaporation, so the holding pump is used to continue extraction.

2. Application Fields

2.1 Pharmacy and Chemical Industry

Vacuum pump enjoys a wide range of application including medicines, pesticides, cosmetics and toiletries, soap and synthetic detergents, surfactants, printing inks and its auxiliaries, adhesives, photosensitive materials, water treatment agents and polymeric flocculants, papermaking auxiliaries, leather auxiliaries, mineral flotation agents, casting chemicals, metal surface treatment agents.

Applicable products: vacuum unit, water ring vacuum pump series, slide valve vacuum pump series, reciprocating vacuum pump series.

Figure 3: The appearance of water ring vacuum pump.

2.2 Vacuum Plating, Vacuum Drying, Surface Treatment

Preparation film layers in vacuum consist of simple substances such as plating crystalline metal, semi-conductor, and insulator, and compound films. Chemical vapor deposition also uses vacuum measures such as reducing pressure, lowering pressure, plasma, etc., but vacuum plating generally speaking, refers to adopt physical methods to deposit films. Vacuum pump plays a vitally important role in plating industry, surface treatment, and drying link.

Appliable products: vacuum unit, root vacuum pump series, slide valve vacuum pump series, rotary vane vacuum series, etc.

2.3 Vacuum Smelting, Brick, Ceramic Manufacturing Industries

The use of vacuum pump is reflected in that vacuum technology is a very critical part of metallurgy and brick and ceramics industries, and it can be used to prevent metals from being oxidized due to high temperature during processing. It discharges water and air existing in brick and ceramics to ensure the premium quality.

2.4 Food Packaging, Milking, and Beverage Industries

Vacuum packaging technology dated back to the 1940s. Polyester, polyethylene plastic films were successfully used in vacuum packaging, and later time witnessed rapid development in vacuum packaging. Vacuum packaging is to completely extract air existing in the packaging container and seal it, maintain a high degree of decompression in the bag where the scarcity of air is equivalent to the effect of low oxygen, so that microorganisms have no living conditions to keep fruit fresh without suffering from rotting.

Applicable products: water ring vacuum pump series, rotary vane vacuum pump series, oil free vacuum pump series, vacuum unit.

Figure 4: A vacuum pump set in a wood box.

Related Info

Six Common Faults and Solutions of Water PumpStructural Characteristics of Vacuum Pump

Working Principles and Characteristics of Common Water Pumps

Four Characteristics of Water Pump in Energy Conservation

The Installation and Maintenance of Water Pump