1. Operation Process of Vacuum Pump

Figure 1: Engineers are operating the vacuum pump.

1.1 Starting and Stopping Operation of Vacuum Pump

About 20 minute’s operation should be done in advance before vacuum pump starts to vacuumize assembling unit. And after oil temperature rises, open extraction valve of assembling unit to extract unit.

When vacuumizing unit, open gas ballast valve to vaporize stream immediately, and oil drain port regularly to release condensed water (every 20 minutes).

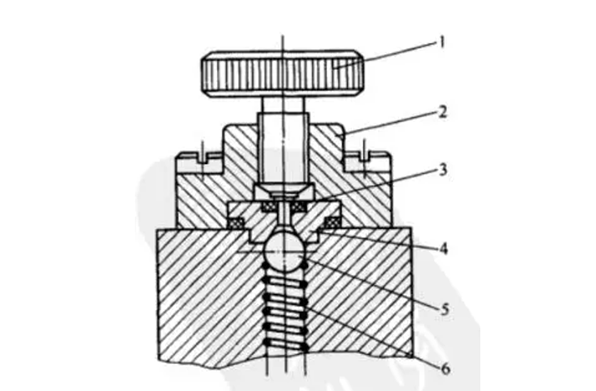

Figure 2: The internal structure of gas ballast valve of rotary-vane vacuum pump.

If main unit has poor vacuum, extraction, in principle should not be opened too largely and fast during the operation, otherwise the LiBr will be easily pumped.

Condensed water at the bottom of the oil stopper should be drained in time to avoid entering the vacuum pump and causing damage.

After closing the extraction valve of the unit, which is about to stop the operation of vacuum pump, the vacuum pump should continue to run for 20 minutes to evaporate the steam in the pump and prevent corrosion in the pump.

Only when it is confirmed that there is non-condensable gas in the unit, can the vacuum pump be started to vacuumize the unit.

It is strictly forbidden to vacuumize the unit blindly, so as not to damage the vacuum pump and destroy the vacuum of the main engine.

1.2 Operation of Measuring Maximum Vacuum Value of Vacuum Pump

1.Connect the Michaelis vacuum gauge to the sampling valve on the oil stopper.

2.Check whether the corresponding valves are closed.

3.Start vacuum pump.

4.Open sampling extraction valve.

5.See the value on the Michaelis vacuum gauge after 3 minutes. (whether the value can reach 30Pa).

Figure 3: The PM-2 type Michaelis vacuum gauge.

2. Maintenance of Vacuum Pump

The operating temperature of the pump is generally controlled within the range of 5-40°C, and the bearing temperature cannot exceed 35°C. It is better to install vacuum pump in a dry, ventilated, clean and stable place.

Designated special oil for vacuum pump must be used, otherwise, the drainage performance of the pump will be affected, the maximum vacuum capacity will be reduced, and the service life of the vacuum pump will be shortened.

Regular replacement of the vacuum pump oil should be ensured, observe the contamination of the oil through the oil level sight glass, and replace the pump oil.

Rising oil level or ivory oil color indicates oil has been emulsified. Loosen the oil drain bolt at the bottom of the fuel tank to release the emulsified oil or water drops.

Figure 4: Different types and specifications of vacuum pump oil.

When the vacuum pump is running, if the oil level of the pump oil is lower than the lower line of the red dot of the oil level sight glass, the pump oil should be replenished immediately until the oil level rises to the upper line of the red dot of the oil level gauge.

If the vacuum pump suspends for a long time, the vacuum pump should be jogged several times before official start so as to avoid damage to the pump due to excessive load when the pump is directly started.

If the LiBr solution enters the vacuum pump due to mistaken operation, the contaminated oil and LiBr solution should be released immediately, and the vacuum pump should be jogged several times to discharge the residual solution, and gradually replace and clean with a small amount of oil until there is no solution.

Related Info

Six Common Faults and Solutions of Water PumpStructural Characteristics of Vacuum Pump

Classification and Application of Vacuum Pump

The Operation and Maintenance of Vacuum Pump

The Installation and Maintenance of Water Pump