Figure 1: Adding oil to the air compressor.

With the improvement of the industry and people's living standards, the requirements for industrial products have also been greatly increased. At the same time, the upgrade of the air compression system has promoted higher requirements for the oil content, water content, and decibel of the compressed gas. In response to market demand, the application of oil-free air compressors was born, and it is popular with the general public. What are their pros? Please keep reading, and you will get it.

Oil-Free Scroll Air Compressor Internal Details & Pros

Oil-Free Scroll Compressor Internal Details

Air filter

High-efficiency paper cylinder type intake can filter dust and particles.

Automatic adjustment

When the required pressure is reached, the compressor will stop automatically to save energy.

Mute cover

It reduces noise, so the compressor can be installed near the place of use.

Human-machine interface

It is used to monitor alarm alerts, maintenance plans and to view operations online.

Coolers and Pipes

Large-size coolers greatly increase unit performance.

Energy-efficiency rotor

As an air-cooled scrolling type rotor, it has the advantages of long service life, stability, and good energy efficiency.

Figure 2: A rotor of the air compressor.

Oil-Free Scroll Compressor Advantages

There is no metal contact between the compression scrolls and no oil lubrication in the compression chamber. Therefore, the working principle ensures clean oil-free compressed air. The oil-free scroll compressor is of high efficiency, using a simple start and stop control, which lacks the loss of unloading power. Scroll compressors are designed with fewer moving parts and to operate for long periods.

Oil-Free Screw Air Compressor Pros

Non-Oil Characteristics

Because the lubricating oil is very sticky, most oil filters cannot completely remove it. However, for the oil-free and water-lubricated air compressor, there is no oil during the whole compression process, which can ensure high-quality gas.

Water Removal Equipment Protection

Before the appearance of high-quality oil-free screw compressors, some water removal equipment would lose its function due to the oil produced in the compressed air during operation.

In addition, now a lot of free dryers, no heat regenerative adsorption dryers, and other water removal equipment on the market, whose water removal efficiency is gradually reduced due to the oil in the compressed air. But the water-lubricated oil-free screw air compressor provides 100% oil-free gas after compression, which not only fully protects the water removal equipment but also reduces the cost caused by its maintenance.

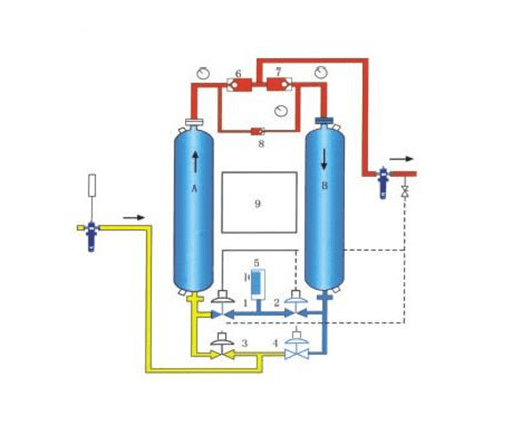

Figure 3: The process of a no heat regenerative adsorption dryer.

Pressure Loss Reduction

The oil-free water-lubricated air compressor will not reduce the load of the motor due to the pressure loss caused by the oil filter to save energy.

At present, the quality tertiary filter in its use process will lose 1 to 1.2 kg pressure. If a screw compressor increases 1 kg of pressure, there will be 7% of power loss. For instance, a 50p air compressor works for 10 hours each day, 26 kWh will be wasted.

Figure 4: A water-lubricated oil-free air compressor.

Save Compressor Oil Cost

Air compressors need to use lubricating oil to ensure high-efficiency operation. But oil-free compressors can use other lubricants to replace the lubricating oil, so as to greatly reduce the use of the oil.

The oil-free air compressor is capable of saving the cost of lubricating oil. Take a 37KW oil-free air compressor as an example, it consumes 20 kilograms of lubricating oil every 2500 hours at least, and 60 kg of oil will be increased in a year.

In addition, to remove the oil in the compressed air, a high-efficiency oil filter is required whose core needs to be replaced many times. The more the filters, the greater the pressure drop. From this point of view, an oil-free air compressor can solve many problems that occur in an oil compressor.

Save Maintenance Expense

The use and maintenance of the oil-free air compressor are also simple and convenient, which can improve work efficiency and accelerate the speed of production. As is known to us all, the regular maintenance of the oil air compressor, including replacing the head and adding lubricating oil, takes time and cost, which relatively increases the user's workload. Both two types of compressors are basically the same in functions and are very suitable for use in the food and medicine industry, and asepsis laboratories.

Figure 5: Two workers are maintaining the air compressor.

Summary

The material of the oil-free scroll air compressor does not contain oil-based substances, and there is no need to add the lubricating oil during the operation, so it greatly improves the quality of the discharge, which adds a layer of protection to the equipment matched by users. Unlike the screw air compressor, the normal compressor discharges the gas containing a large number of oil molecules. It will bring pollution and corrosion to the equipment and products produced by users, so the choice of the oil-free silent air compressor is the guarantee of air quality.

It can be concluded that on the premise of comprehensive consideration of enterprise production requirements, water-lubricated oil-free screw air compressors have the advantages of energy-saving, pollution reduction, and fewer costs. At present, the oil-free compressors on the market can be divided into screw compressors, piston compressors, and scroll compressors. Among them, oil-free screw air compressors are more used in pure compressed air industry applications thanks to their oil-zero characteristics.

Related Info

How to Prevent Air Compressor High Oil ConsumptionFactors Affecting Service Life of the Air Compressor Oil

Causes of Oil Separator Burning