In which cases will a servo motor vibrate? What happens if the servo motor vibrates? How can we solve the problems caused by the vibration? This article will explain various reasons for this.

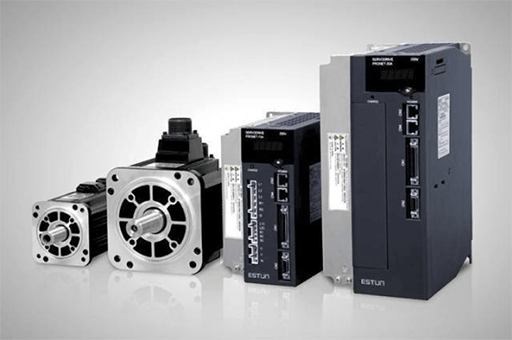

Figure 1: Servo motors and servo drives.

1. Reason for Servo Vibration

1.1 High Gain of Servo Motor

When the servo motor vibrates with its speed at zero, the reason for the vibration may be that the gain is set too high. Try to reduce the gain value. At startup, if it vibrates to stop, it’s most likely that the motor phase sequence is not correct.

1.2 Large PID Gain Adjustment

When the PID gain adjustment is too large, it is easy to cause motor vibrate, especially after adding D. So try to increase P, reduce I, and it is better not to add D.

vibration will also occur when the encoder connection is wrong.

The load inertia is too large. You could replace a larger motor and drive.

Interference of the analog input causes vibration. Add magnetic ring in the motor input line and servo drive power input line, so that the signal line gets away from the power line.

There is also a rotary encoder interface motor, which is easy to cause vibration if the grounding is not good.

1.3 Wiring and Mechanical Reasons

* Problems Exist in Servo Wiring

Use standard power cable, encoder cable, control cable. Check whether the cable is damaged.

Check whether there is interference source near the control line, whether control line is parallel to or too close to the nearby high-current power cable.

Check whether the grounding terminal potential has changed to ensure good grounding.

Figure 2: Appearance of grounding terminal.

* Problems Exist in Servo Parameters

If the servo gain is set too large, it is recommended to re-adjust the servo parameters manually or automatically.

Confirm the setting of the time constant of the speed feedback filter. The initial value is 0, and you can try to increase the setting value.

If the electronic gear ratio is too large, it is recommended to return it to the factory setting.

Resonance of servo system and mechanical system. Try to adjust the frequency and amplitude of harmonic filter.

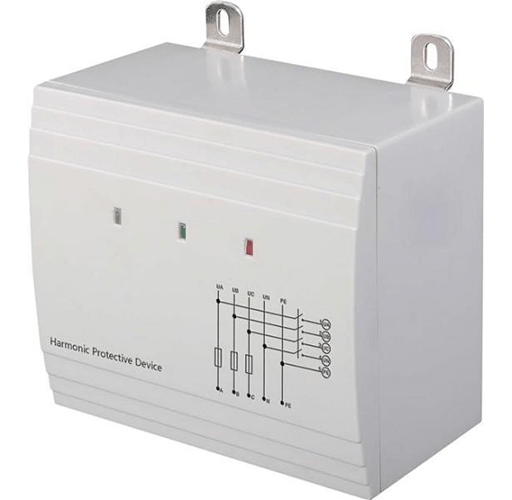

Figure 3: A kind of harmonic protective filter.

* Problems Exist in Mechanical System

The coupling connecting the motor shaft and the equipment system is offset, and the mounting screw is not tightened.

Poor occlusion of pulley or gear will also lead to load torque variation. Try to run without load. If the no-load operation is normal, check whether there is any abnormality in the joint part of the mechanical system.

Verify whether the load inertia, torque, and speed are excessive. Try to run without load. If the no-load operation is normal, reduce the load or replace the drive and motor with a larger capacity.

1.4 Mechanical Structure Problem

Servo motor vibration caused by mechanical structure, speed loop, servo system compensation plate and servo drive, load inertia, electrical parts and other faults.

Summary of Why Servo Motor Vibrates

2.1 Motor Vibration Caused by Mechanical Structure

The vibration caused by mechanical structure can be divided into two cases:

* Non-Load Vibration

The motor has a weak foundation, insufficient stiffness or loose fixation.

The fan blade is damaged, destroying the mechanical balance of the rotor.

The shaft is bent or cracked. It can be solved by fastening screws, replacing fan blades, changing machine shaft and so on.

* Load Vibration

The vibration after loading is generally caused by the failure of the transmission device, it can be judged that the following parts are defective:

Unbalanced rotation of belt wheel or coupling.

The center line of the coupling is inconsistent, so that the motor does not coincide with the mechanical axis it drives.

Unbalanced transmission tape joints. It can be balanced by correcting the transmission device.

2.2 Vibration Caused by Speed Loop

Improper parameters such as velocity loop integral gain, velocity loop proportional gain and acceleration feedback gain. The greater the gain, the greater the speed, the greater the inertia force, the smaller the deviation, the more easy to generate vibration. Setting the servo motor’s gain at a small value can maintain the speed response, ensuring it less prone to vibration.

2.3 Problem of Compensation Board and Servo Amplifier

The motor stopped suddenly when moving, resulting in great vibration, which is related to the servo drive BRK terminal and improper setting parameters. The acceleration and deceleration time constant can be increased, and the motor can be started or stopped slowly by PLC to avoid vibration.

Figure 4: Fuji servo drive RYH401F5-VV2

2.4 Vibration Caused by Load Inertia

Problems with guide rail and screw lead to increased load inertia. The rotational inertia of guide rail and lead screw has a great influence on the rigidity of servo motor transmission system.

With fixed gain, the greater the rotational inertia is, the greater the rigidity is, and the easier it is to cause motor vibration. The smaller the moment of inertia, the smaller the rigidity, the motor is not easy to shake.

By replacing the guide rail and screw with smaller diameter to reduce the moment of inertia so as to reduce the load inertia to avoid vibration.

2.5 Vibration Caused by Electrical Parts

The brake is not open, the feedback voltage is unstable and other factors. Check whether the brake is open. This can be solved by adding the encoder vector control zero servo function and output a certain torque in the way of torque reduction. If the feedback voltage is not normal ,you should first check whether the vibration period is related to the speed. If relevant, you should check the connection of the spindle and the spindle motor, and pulse generator at the end of the AC spindle motor etc.. If not, you should check whether there has fault on a printed circuit board.

The sudden vibration of the motor during operation is mostly caused by the lack of phase. It should focus on checking whether the melt of the fuse is fused, whether the switch contact is good, and measuring whether each phase of the power grid has power.

Related Info

Basics of Servo Motor You Should KnowWhere is Servo Motor and Servo Drive Used?

Case Studies of TECO Servo Drive and Servo Motor

Application of Servo System in Textile Machinery